Basic Introduction

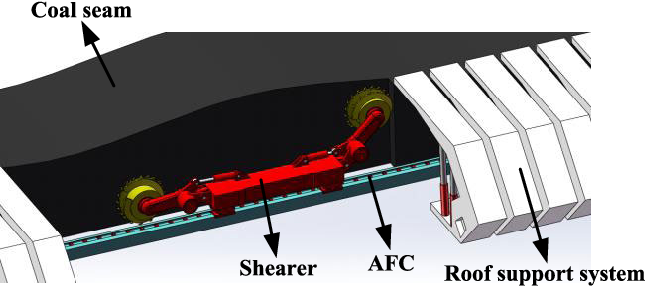

At present, large coal mines currently use shearers for mining. The shearer is core equipment for the fully mechanized coal mining face. During operation, the worker follows the machine and adjusts the working mode of the hydraulic support on shearer track (the mining efficiency is the highest when the track is straight). Moreover, manual adjustment of the track can only be started after the end of a mining cycle, which is not efficient and has potential safety hazards. Obtaining accurate shearer position and attitude information and the running track of shearer is key to realizing coal mine automation and unmanned mining.

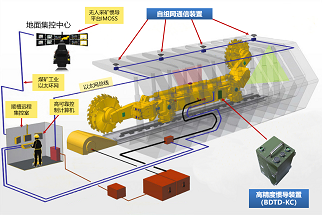

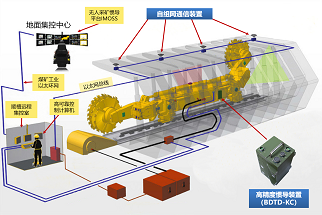

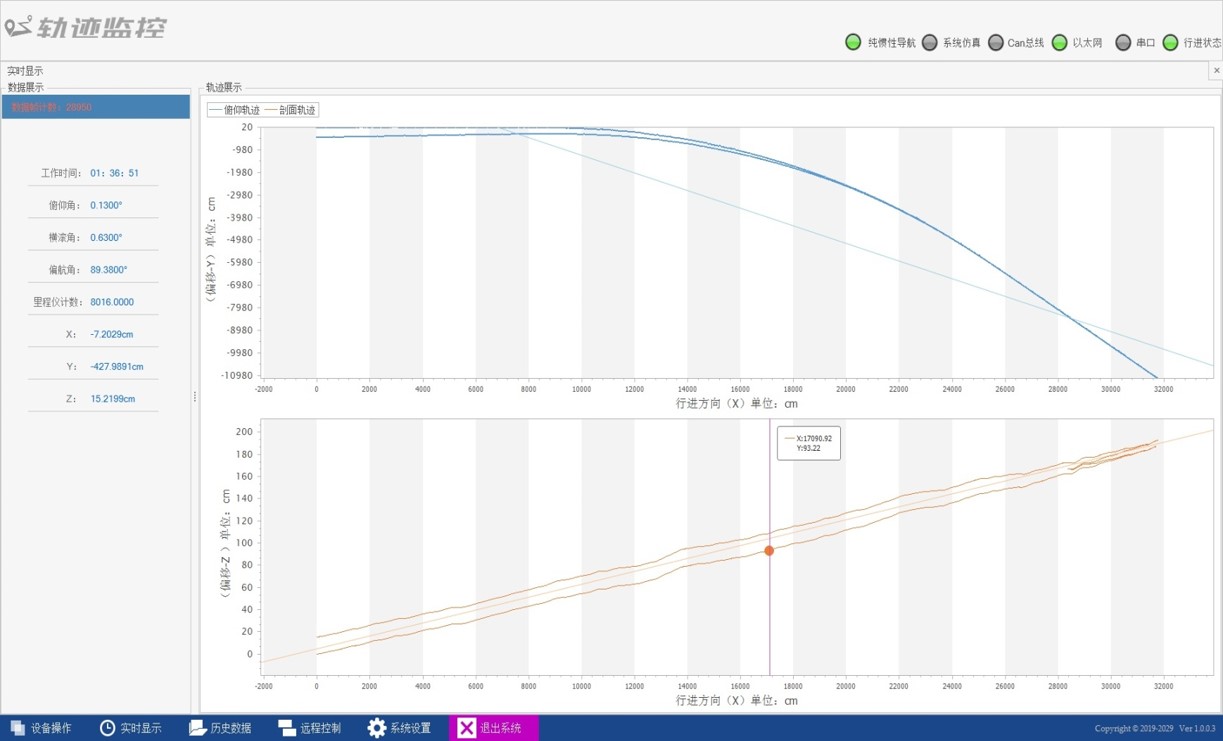

The Precision inertial measurement system is an automated coal mining system based on gyro-guided positioning (LASC) technology. Through the high-precision inertial navigation system, the real-time position and attitude of the shearer are measured, and the operation track of each shearer is given. Based on the self-developed straightening algorithm, the system can obtain the process amount of each ejector rod for the next cutter of the shearer, realize the relative parallel and straight-line operation of each cutter, so as to improve the working efficiency and safety of the shearer, and finally realize the automatic straightening of the running track of the shearer.

The first-generation products are based on military high-precision laser inertial measurement systems, and now the development of the third-generation system has been completed, which is based on high-precision fiber optic gyroscope and has been applied in the actual mining environment.

Hardware Devices

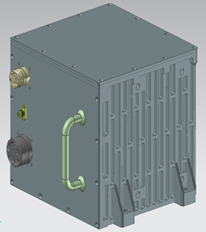

The high-precision inertial navigation positioning deviceis mainly constructed by two parts, a high-precision optical gyroscope and an accelerometer. With small size and large power, it is better than most of the current GPS systems, and is more adaptable to the coal mine environment. The device can measure the heading, pitch, and roll three-dimensional space angles of the shearer in the working process, and combine it with a high-resolution odometer. The measured data is fused and calculated by multi-source data to obtain the shearer's running trajectory.

System Advantages

High precision inertial measurement system: Inertial / log combination technology

Automatic straightening algorithm of working face: According to the measurement results of inertial positioning system and constraint conditions, the trajectory of shearer is fitted and drawn in real time; The automatic straightening function can liberate personnel from the coal mining site and basically eliminate the occurrence of personnel safety accidents.

Comprehensive information processing unit: The processing unit can generate the track of Shearer in real time and display it in graphic form.

Application Effect and Economic Benefit

The system can increase the mining efficiency by about 20-30%, increase the annual coal mining volume by about 3 million tons, save 5-6 on-site operators, and increase the annual benefit by about 400 million yuan.

Contact us

Email: sales@hot-mining.com

Tel:+86 28 8331 1885