Usually, coal washing plants typically rely on manual medium feeding methods, which result in low work efficiency, insufficient precision in medium feeding, high labor intensity, operational risks, and difficulties in remote control.

The existing medium feeding methods cannot meet the requirements for automation and intelligent production. Additionally, data statistics pose challenges, making precise data calculation difficult.

System Introduction:

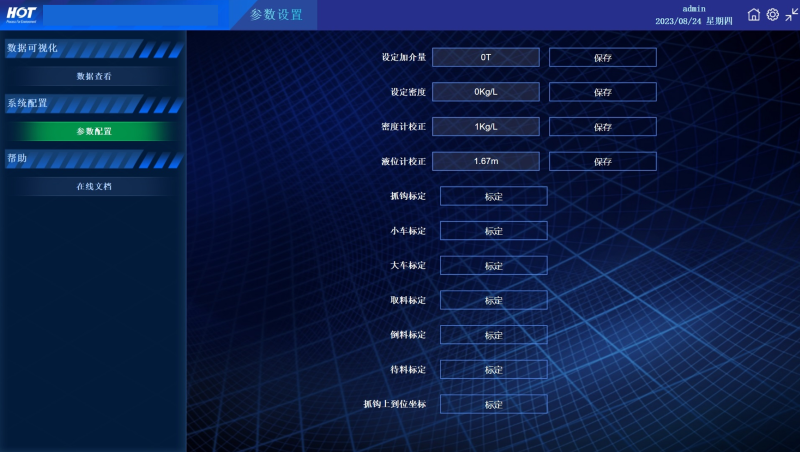

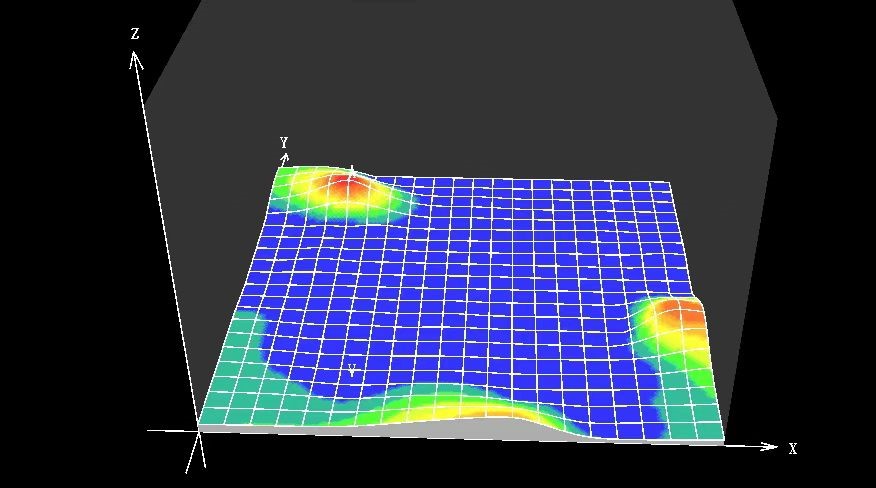

The Intelligent Dense Medium Feeding System utilizes key instruments such as 3D level laser radar, 3D measurement software, and an intelligent dense medium feeding system, complemented by a self-developed software platform.

This system aims to effectively optimize the dense medium feeding process(DSM), precisely monitor crucial data and outcomes. It achieves functions such as 3D automatic detection and measurement of medium powder materials, automatic material retrieval and measurement, automatic dense medium feeding ratio control, and automatic dense Medium transport. The goal is to achieve intelligent dense medium feeding.

The Intelligent Dense Medium Feeding System has a total of three modes:

1. Manual Mode:

Control Room Configuration Software: Users can input the medium quantity or frequency through the software to perform tasks such as crane positioning, material retrieval, unloading, and tracking the weight of the medium powder.

Valve Control: The configuration interface allows users to switch valves and display the status of water supply and air blower valves.

On-Site Control: Remote control for cranes and pump control buttons are retained for on-site operations.

2. Cyclic Automatic Mode:

Process Breakdown: This mode divides the entire process into three steps, namely, Medium preparation, aeration, and medium transport, with parameters set on the main control touch screen.

One-Click Operation: Users can simply click a button to automatically complete the entire process without manual intervention.Fully Automatic Mode.

3. One-Click Media Feeding:

In this mode, users can set buttons on the operating interface to automatically execute the medium preparation, aeration, and medium transport processes based on predefined density parameters.

Intelligent Assessment: The system incorporates intelligent judgment; if medium feeding is unnecessary, it will skip the automatic Media Feeding process.

These three modes provide diverse operational options for the intelligent dense medium feeding system to meet various work requirements and operational scenarios.