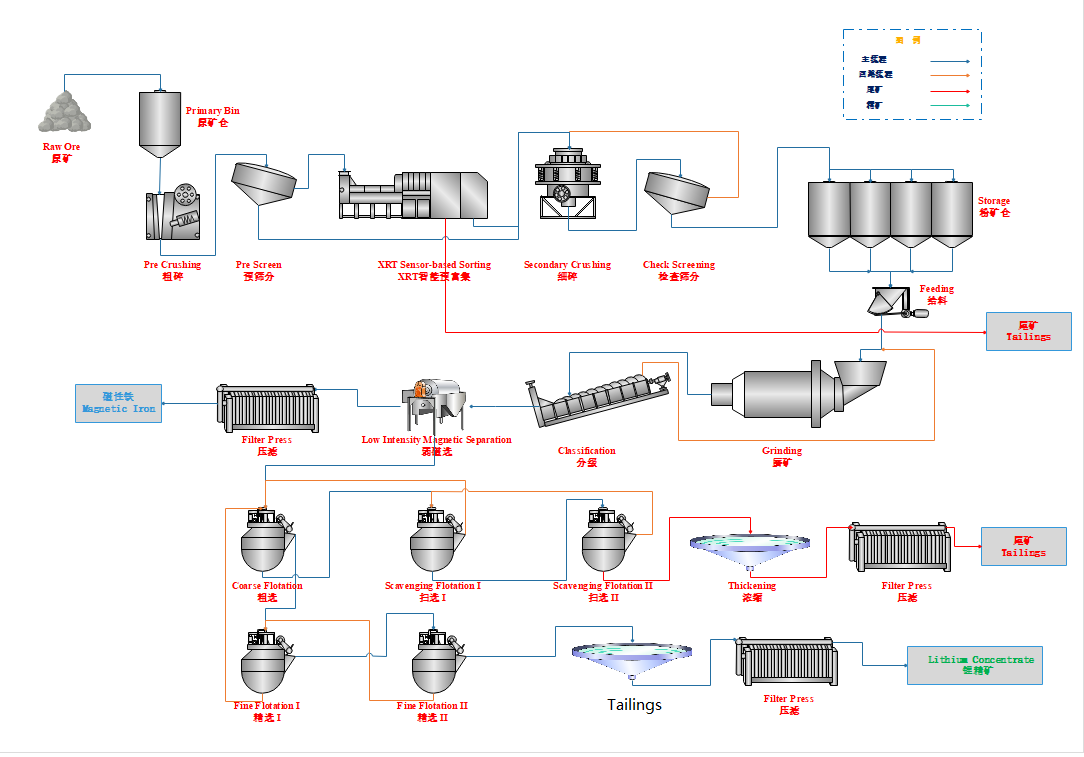

Crushing and XRT pre-concentration

The crushing system has two stages crushers and a closed-circuit screen.

The raw ore is fed into a jaw crusher for primary crushing. Discharge from the jaw crusher will enter check screening, from which coarse fraction will be attained over the screen deck and sent to XRT sorting.

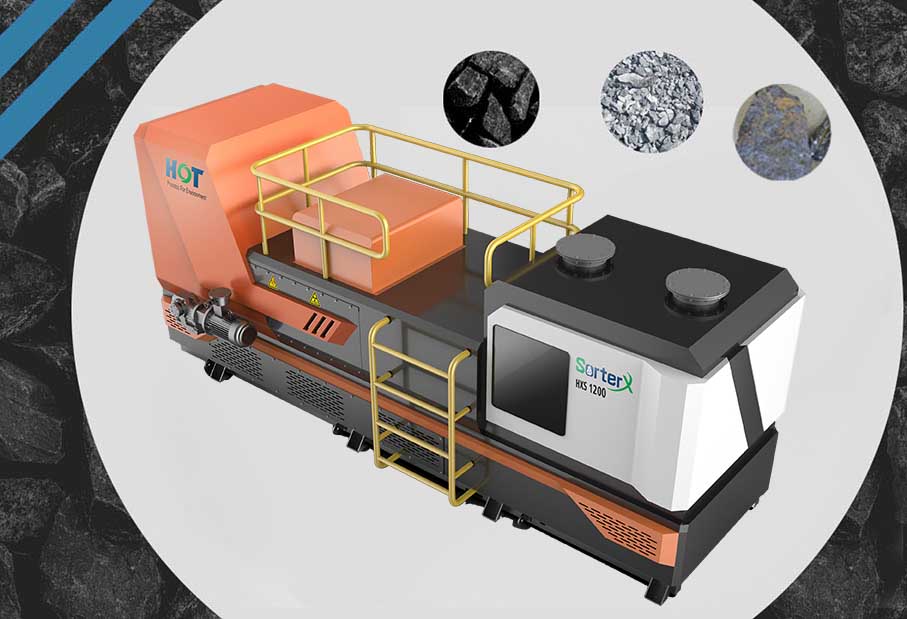

The XRT sorting is based on advanced sensors, advanced AI algorithms, and machine learning and utilizes X-rays to identify different mineral compositions. Coarse mineral fraction is discretely arranged along a belt conveyor inside the XRT sorter and moved forward. An X-ray generator inside the sorter will radiate directional X-rays to penetrate the mineral. A sensitive plate behind the belt will collect the X-ray radiate, transform it into an electronic signal, and then send the call to a computer for mineral identification. A pneumatic mechanism located at the discharge end will eject high-velocity airflow to reject waste rock precisely according to the command from the computer. Spodumene is primarily concentrated and sent to the secondary crushing; the waste rock will be dismissed to the stockpile.

One or more cone crushers are used for secondary crushing. Discharge from the cone crusher will be transported to a vibrating screen for checking to screen. The oversize part will be detained from up on the screen and transported back to the cone crusher, while the undersized part from under the screen is qualified and transported to a storage bin, called a grinding bin. For this part of material enters into the grinding bin, their size is often less than -10mm. The process above forms a closed circuit.

Tips: about XRT sorting

XRT sorting is on behalf of a leading technical trend in mineral beneficiation. The grade of functional composition will increase while grinding consumption (energy, balls, plate, water consumption) will decrease after a large amount of waste rock is rejected precisely. Therefore, its operation cost is relatively low when it helps with more margin for investors.

Click here to know more about XRT sorting.

Grinding and classification

Fine material from the grinding bin will be transported and fed with water into a ball mill for grinding; discharge from the mill is slurry. Slurry from the mill goes into a spiral classifier for classification. The underflow part of the spiral classifier is coarse; it goes back to the mill and is ground again. Thus forms a closed circuit. The overflow part of the classifier is delicate enough and enters the separation sector.

Separation sector

Fine slurry initially goes into a low-intensity magnetic separator to remove magnetic particles. After that, the slurry enters flotation machines for primary float flotation, called rough floatation. Next, concentrate from the rougher concentration enters two stages of sequential flotation machines for further separation, called cleaning floatation. Finally, tailings from the rougher concentration enter two sets of sequential floatation machines for reclaiming valuable spodumene, called scavenging flotation.

The tailings from cleaning concentration and the concentrate from scavenging flotation go back to rough floatation. This will form a closed circuit.

The concentrate from cleaning floatation is qualified, often with a Li2O grade ranging from 5~6%. The tailings from scavenging floatation are eligible for discarding.

Thickening and dewatering

The concentrate and the tailings are transported into thickeners for thickening. Then, the underflow part from the thickeners is transported into press filters for dewatering. After that, the final product and final tailings are obtained. Finally, they will be stocked irrespectively and waiting for transportation.

Process flow diagram above is illustrated blow in Fig.1.

Fig.1. The PFD of the spodumene beneficiation plant with XRT sorting

Fig.2. A spodumene floatation workshop

Fig.3. Spodumene concentrate