What is LIBS?

LIBS: Laser-induced Breakdown spectroscopy.

It is an elemental analysis technology developed based on the principle that the atomic and ion spectrum wavelength has a one-to-one correspondence relationship with specific elements. Consequently, the spectral signal intensity has a particular quantitative connection with the content of corresponding elements.

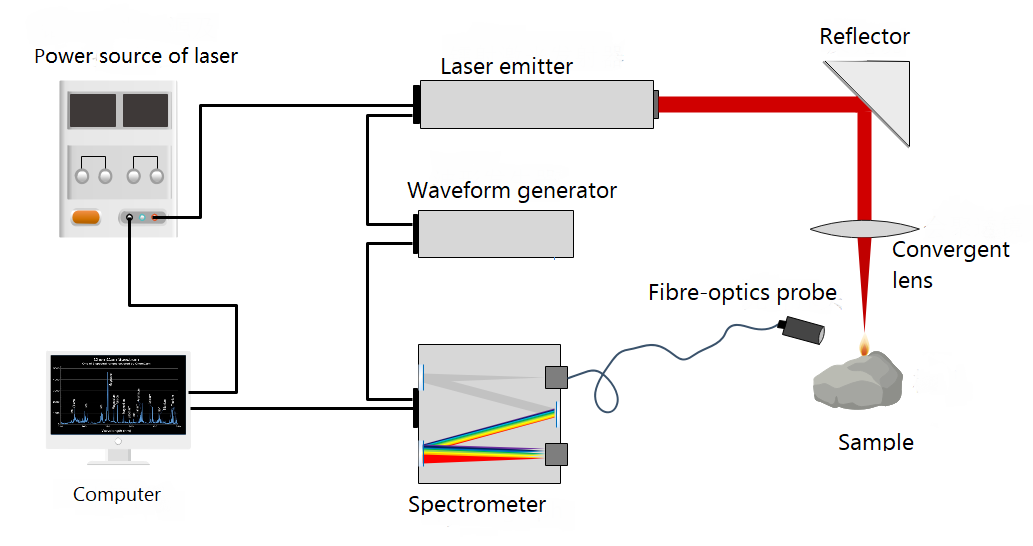

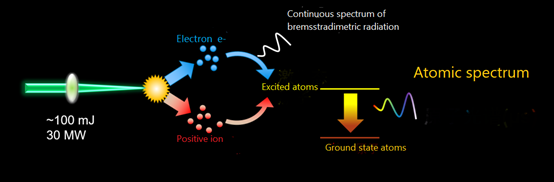

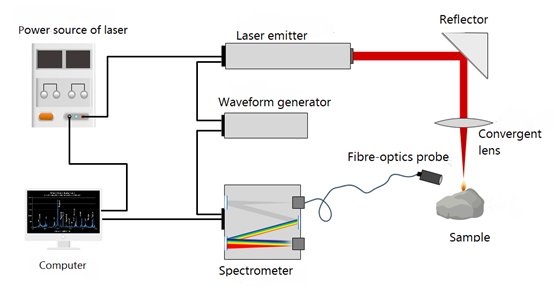

Schematic diagram of laser induced plasma spectral excitation

(Figure from the network, if involved in infringement, inform us to delete it.)

Laser-induced fast elemental analysis technology can be developed based on the LIBS principle. It takes a high-energy laser as the excitation source, irradiates the surface of the sample with high energy pulse laser (within a few nanoseconds), converts the sample of the illuminated area into plasma, combines with an elemental spectrum analysis system, carries out a thorough analysis on characteristic spectrum produced by plasma, the sample can be rapidly analyzed on quality and quantity in a short period, thus obtain the information of each element contained in the model.

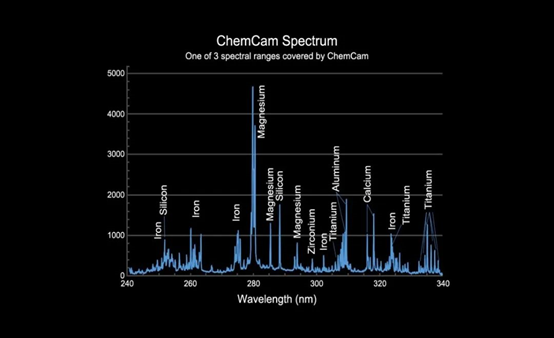

LIPS element analysis of Martian soil.

(Figure from the network, if involved in infringement, inform us to delete it.)

Principle, advantage and application of laser-induced elemental analysis technology based on LIBS

Based on LIBS principle, laser induced fast elemental analysis technology can be developed. It take high-energy laser as the excitation source, irradiate the surface of sample with high energy pulse laser (within a few nanoseconds) , convert the sample of irradiated area into plasma, combined with elemental spectrum analysis system it carries out a special analysis on characteristic spectrum produced by plasma, the sample can be rapidly analyzed on quality and quantity in a short period, thus obtain the information of each element content in the sample.

Principle of LIBS laser elemental analyzer

Compared with other traditional elemental analysis technologies, laser elemental analysis technology has the following advantages:

1. Qualitative and quantitative analysis of almost all elements;

2. It can conduct almost nondestructive analysis on various forms of substances (solid, liquid and gas);

3. Non-uniform samples can be analyzed without pretreatment;

4. Fast analysis speed, sample analysis can be completed in a few seconds, online analysis can be done;

5. Safe without radiation, without any physical damage to the operator;

6. Non-contact analysis, can deal with a variety of environments.

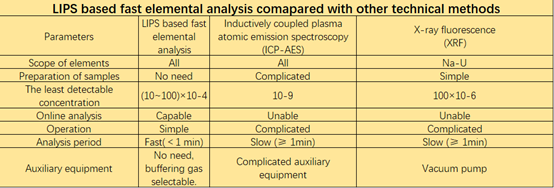

Comparison of laser-induced Extreme velocity element analysis based on LIPS with other techniques

Fast elemental analysis based on LIBS laser-induced plasma technology has a wild applicability. Therefore, it’s application can be developed based on this technology for different industries, such as:

1. Metallurgical engineering

2. Gem identification

3. Archaeological analysis

4. Biomedical science

5. Food industry

6. Military uses

7. Environmental detection

8. Material analysis

9. Space mining

Online analysis system of coal integral composition

Development Background:

Intelligent perception is the first problem in the intellectual construction of coal preparation plants, and online analysis of ash content is the most urgent problem. LIBS has emerged for coal preparation plants to provide real-time analysis online and control costs.

The existing coal ash analysis methods are divided into four kinds:

1. Traditional analysis method: there are many problems, such as manual sampling and testing, and there are potential safety hazards; The time lag of output results makes it difficult to realize intellectualization

2. Active online ash analyzer: expensive and fast attenuation of radioactive source

3. Passive online ash analyzer: the application of the universality is not comprehensive, and the analysis accuracy and precision are not good

4. Other ash content analysis methods: laser-induced plasma spectroscopy, which achieves spectrum and ash content analysis.

Technical principle:

By irradiating the surface of coal with a high-energy pulse laser (time width of several nanoseconds), a high temperature of more than 10,000 degrees is generated in the area within several microns, which causes the formation of plasma of the coal in this area, and various elements in the plasma will glow. By measuring the spectrum, the content information of each component can be obtained. .

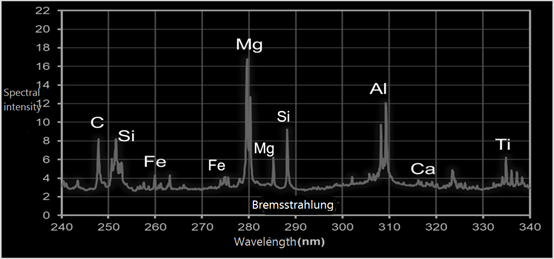

Typical spectrum of coal, Panpanta flotation feed slime, ash content :26.25%

(Figure from the network, if involved in infringement, inform us to delete it.)

Application

Industrial tests were carried out from November 2020 to July 2021 at the Panpanta coal preparation plant, which has been used for nearly a year. The test results show that the laser ash meter is simple to maintain and stable to function, which verifies its performance in high humidity, high dust content, intense vibration, frequent temperature variation, and online conditions. For repeated testing of the same coal sample, the absolute error of this method is less than 0.2%, and the fundamental mistake of manual test results is less than 0.3%, which suffices the requirements of the national standard for testing error. The error of online test results in production is about 0.4%.

It's now in use in the Yueliangtian coal dressing plant of Panjiang Group and the Longwanggou coal preparation plant of Datang Group, etc.

Notice

The content of each element in coal can be determined online by LIBS, which can accurately obtain the industrial analysis indexes of ash content, sulfur content, fixed carbon content, volatile matter content, and calorific value of coal.

LIBS coal integral component analysis system is safe without radioactive sources and can realize high accuracy and high precision online analysis of coal total elements. It has the characteristics of small volume, simple installation and debugging easy operation and maintenance. In addition, it can provide an effective perception method for the intelligent construction of coal preparation plants.

Using an artificial intelligence algorithm based on machine learning and data mining to process spectrum and ash content data, the output and ash content values can be highly consistent. For repeated testing of the same coal sample, the absolute error of this method is less than 0.2%, and the fundamental mistake of manual test results is less than 0.3%, which suffices the requirements of the national standard for testing error. The error of online test results is about 0.4%. (ash content less than 15%).

Contact us:

Mr.Tari

Tel:+86 15927439651

WeChat: wb15927439651

Mr.Kurt

Tel: +86 18160016286

WeChat: kurt553014