The Horizontal Decanter Screen Bowl Centrifuge, commonly known as the Screen Bowl Centrifuge, combines centrifugal sedimentation and filtration to efficiently dewater fine particles like 0.045-1mm flotation concentrates, tailings, and slimes. This continuous solid-liquid separation device surpasses pressure filters in processing capacity, residual moisture reduction, compact footprint, energy efficiency, and simplicity of operation.

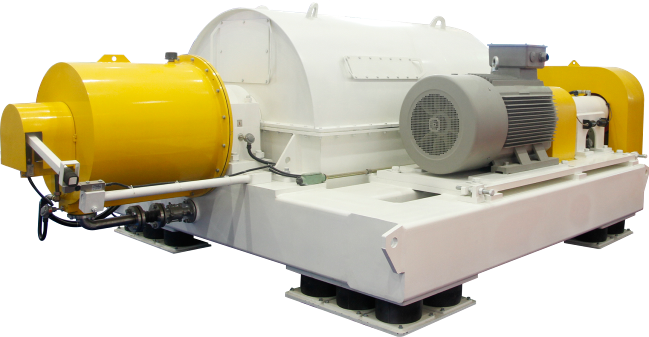

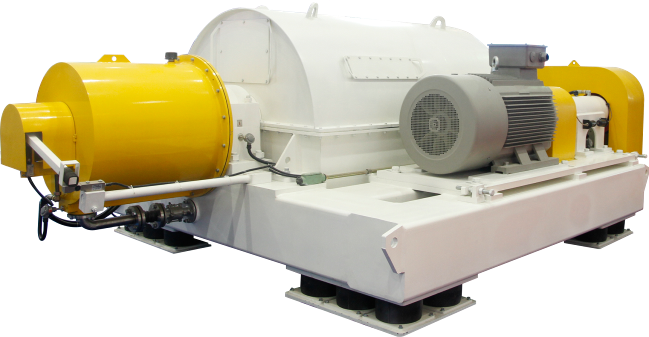

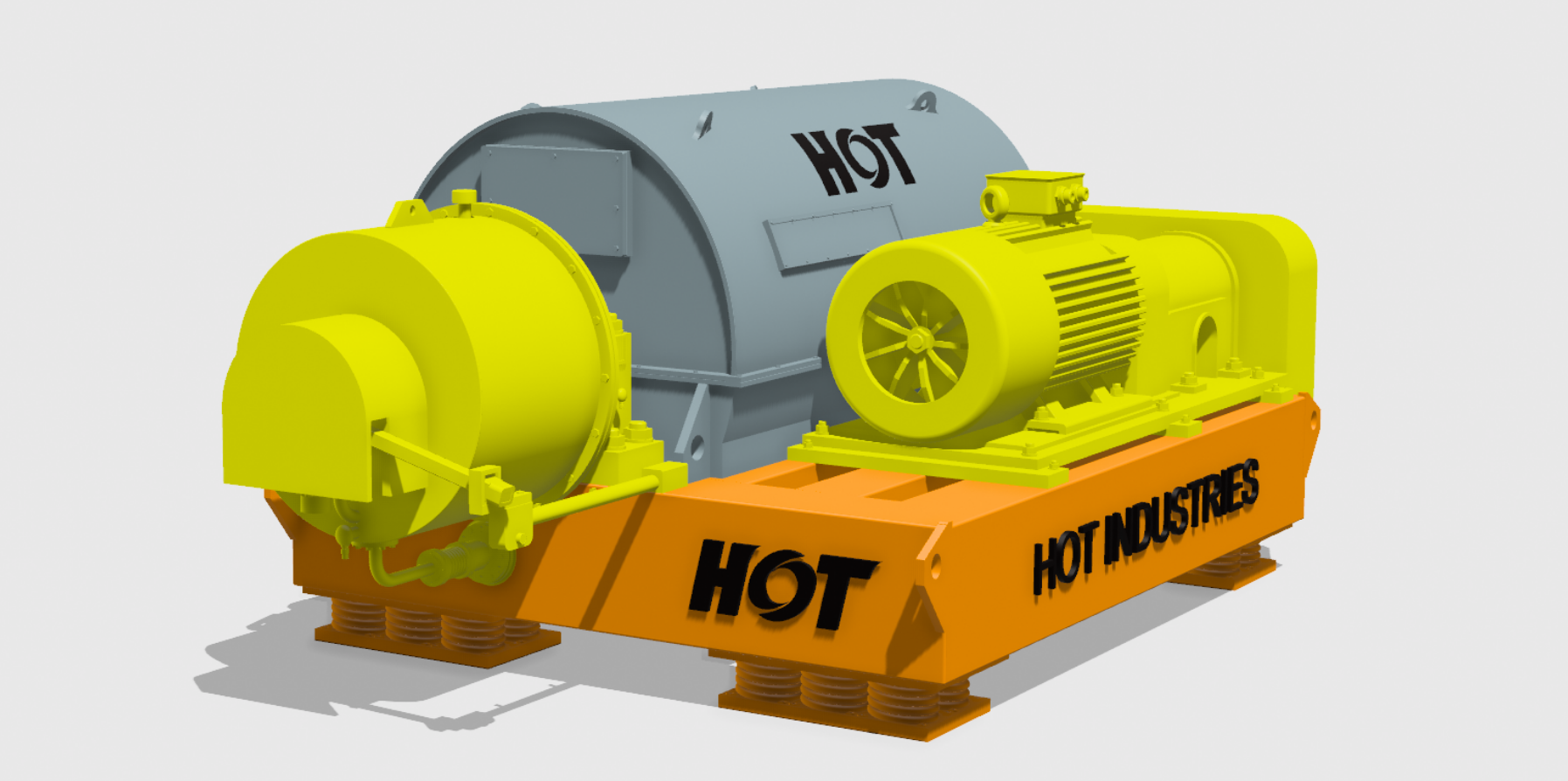

Developed by HOT (Chengdu) Industries Co., Ltd., this centrifuge incorporates advanced international design principles and several innovative features. Engineered for coal washing plants that demand high workloads and extended operational periods in harsh environments, the DSBC series ensures reliable, long-lasting performance.

Working Process

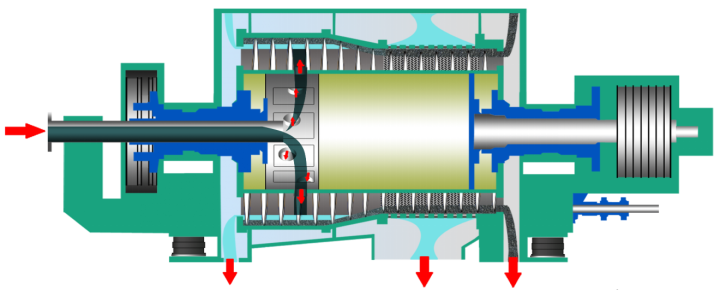

The DSBC Series Horizontal Decanter Screen Bowl Centrifuge integrates several key stages to achieve efficient solid-liquid separation and dewatering of fine coal particles.

1. Mixing and Acceleration Stage: In the specially designed feed chamber, slime water is mixed and accelerated for optimal separation.

2. Clarification Stage: Under centrifugal force, particles quickly separate and settle, with clarified liquid discharged through the overflow weir.

3. Compression Stage: The spiral propeller pushes settled solids to the compression section, further compressing them and releasing interstitial water.

4. Filtration Stage: The solids advance to the screen filtration section, where they undergo further dewatering under centrifugal force.

5. Discharge Stage: The dewatered solids are expelled by the discharge scraper.

Key Features and Structures

The DSBC Horizontal Decanter Screen Bowl Centrifuge excels in dewatering ultra-fine coal slurry through centrifugal sedimentation and filtration technology. Key features include:

· Full Automation: Seamless operation with minimal manual intervention.

· Ultra-Fine Solid-Liquid Separation: Efficiently handles fine particles for superior dewatering.

· Durable Design: Built to withstand rigorous operational demands.

· Easy Maintenance: Simplified maintenance processes for prolonged equipment life.

· Automated Monitoring: Real-time performance tracking and predictive maintenance.

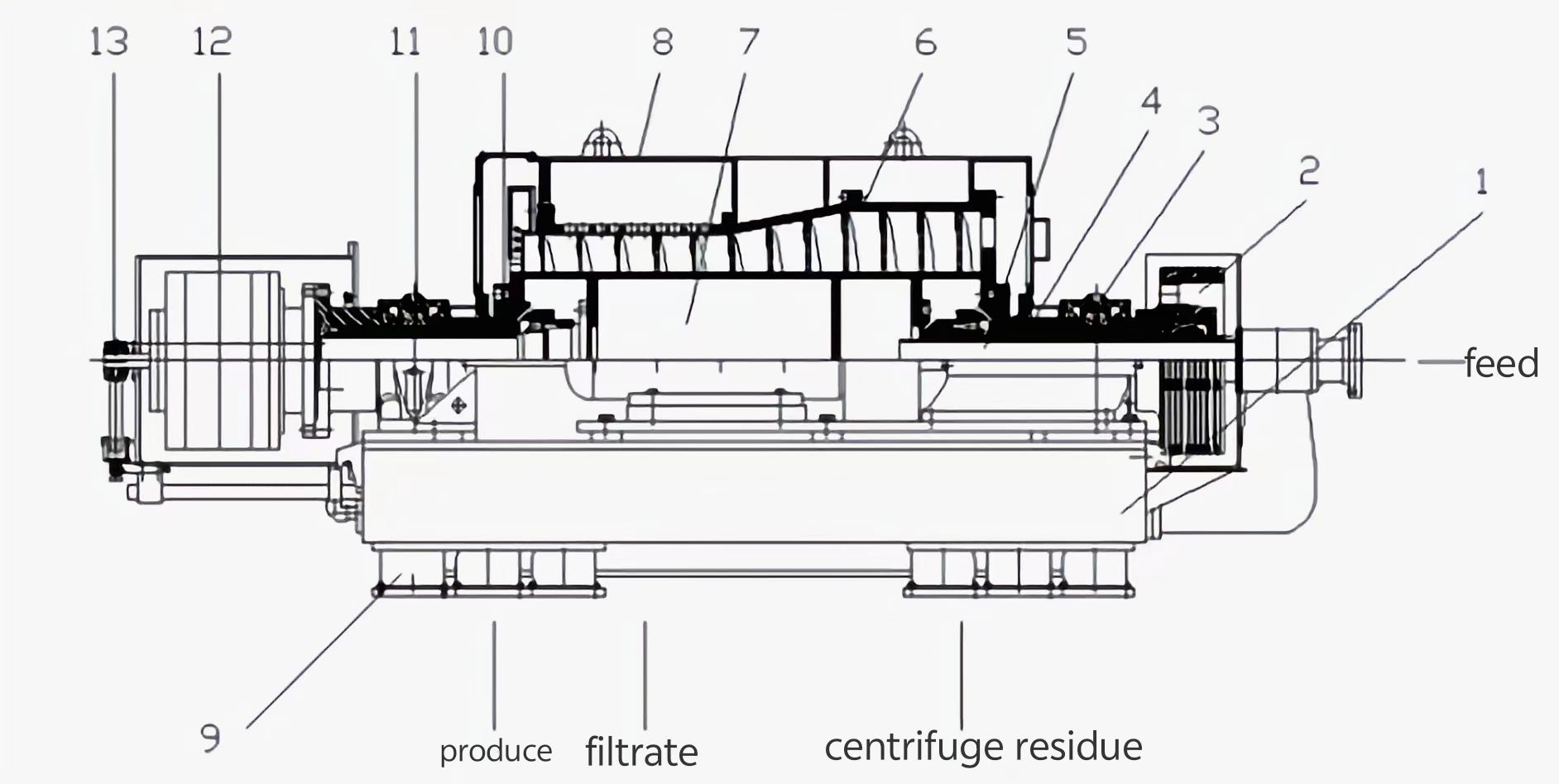

1—Base;2—Transmission Device;3—Floating Bearing;4—Big-Support Shaft;5—Feeding Pipe;6—Basket;7—Screw;8—Upper and Lower Shell;9—Shock Attenuation Device;10—Small-Support shaft;11—Solid Bearing;12—Large Torque Planetary Gear Differential;13—Safety Device;

Technical Parameters

Model | DSBC0918 | DSBC1218 | DSBC1420 | DSBC1133 |

Capacity | 15-25 t/h· | 20-30 t/h· | 40-50 t/h· | 30-70 t/h· |

Maximum Revolution | 850r/min | 643r/min | 534r/min | 1000r/min |

Bearing | Under normal operating conditions and with proper maintenance, ≥8000 hours or at least 1.5 years. | |||

Centrifuge Endurance | Under proper maintenance, ≥12 years. | |||

Power | 380V/660V | 380V/660V/6000V/10000V | 380V/660V/6000V/10000V | 380V/660V/6000V/10000V |

Dimension | 4850mm×2800mm×1550 mm | 5990mm×3200mm×1820 / 1920 / 2190mm | 5370mm×3400mm×1900 / 1920 / 2190mm | 6660mm×3420mm×1925mm |

Weight | 12000Kg | 17500Kg / 19500 Kg / 20500 Kg | 18000Kg / 20000 Kg / 21000 Kg | 23000 Kg |

Centrifuge Intelligent Monitoring System

To ensure long-term performance, the DSBC series includes a customized built-in wireless sensor that monitors core component operations in real-time. Data is uploaded to the cloud for intelligent analysis and predictive maintenance, minimizing downtime and extending equipment life. Real-time monitoring and alerts are available via computer and mobile devices.

Contact us

Email: sales@hot-mining.com

WhatsApp: +151-0833-3341