As the most energy consumption equipment for mineral processing factories, the ball mills occupy more than 50%of the energy consumption of the entire plant. Therefore, even if it improves the milling efficiency by 1%, this will bring huge production income to the mineral processing factories, while saving a lot of energy sources.

By leveraging the rich experience of our engineers, massive grinding data, a full set of test equipment and monitoring equipment, HOT can help mining enterprises effectively improve grinding power.

Parameters that affect grinding efficiency:

1. Steel ball type, size, density;

2. Mining grading circuit parameters;

3. The structure inside the grinding machine;

4. The parameters of the grinding machine;

5. The density and filling of the slurry;

In order to optimize the grinding process, the most important parameter, the mill feed fill level, needs to be measured as precisely as possible. However, this critical parameter cannot be measured directly, but is determined by monitoring the sound and vibration of the mill.

The previous measurement method was to judge the mill filling amount by monitoring the noise in the mill cavity through the microphone, but due to the different noise in the production environment of different factories, the sound monitoring accuracy was extremely low, which had no effect on determining the mill filling amount.

Today, all these drawbacks of noise sensors can be avoided by measuring sound directly where it occurs (on the mill workshop). Through the monitoring and analysis of these parameters, the AI optimization of the grinding grading power is realized.

System Introduction

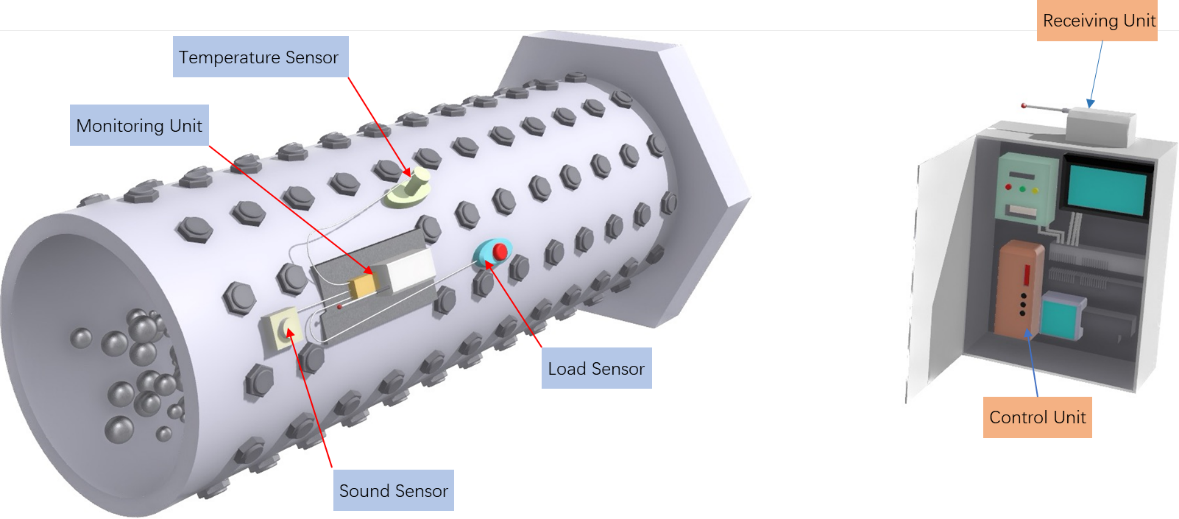

Grinding & classification power AI intelligent optimization system consists of two distinct parts.

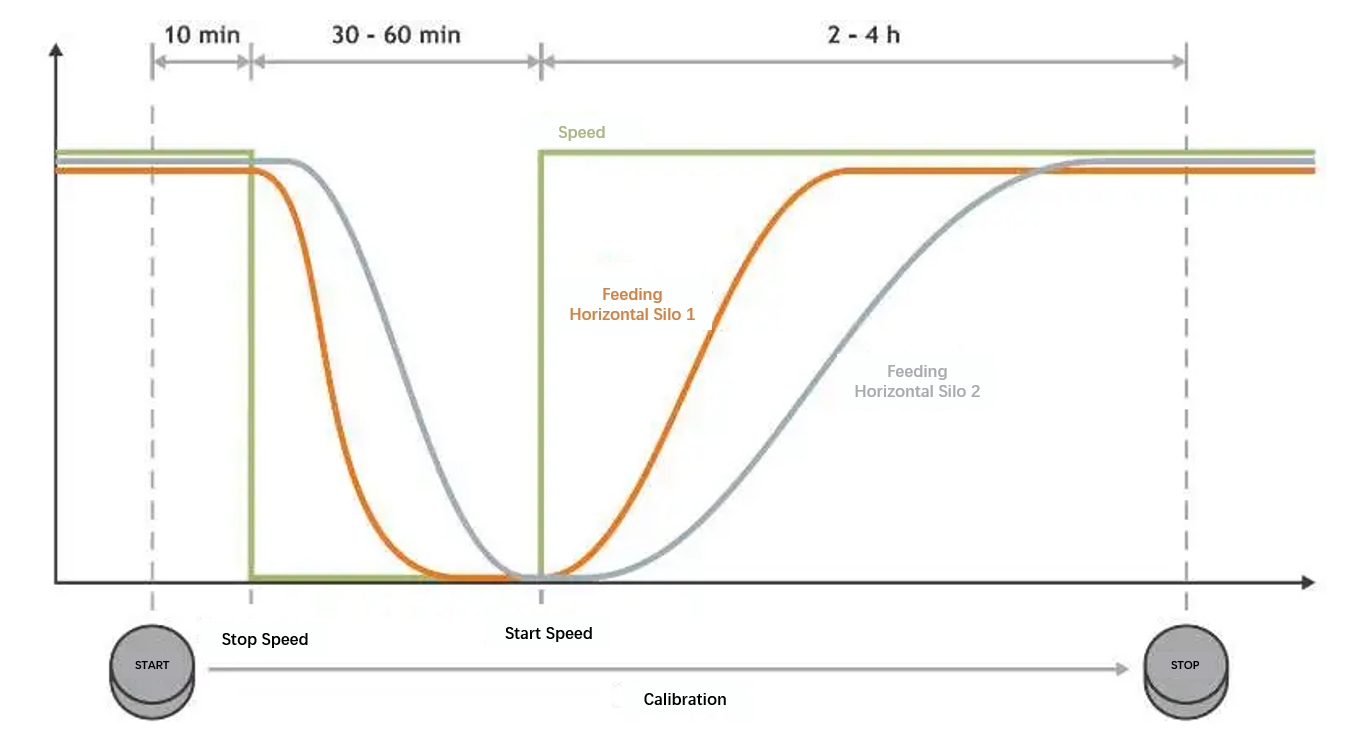

Parameter monitoring: The monitoring system is installed on the ball mill with a monitoring unit including temperature, vibration, sound, load and other parameters. It can wirelessly send the real-time operation data of the ball mill to the receiving unit, and the receiving unit is further transmitted to the basic control unit, which can realize the basic control of the ball mill according to the built-in calculation results of the single machine, and at the same time can transmit the received digital and analog quantities to the central database through the PLC.

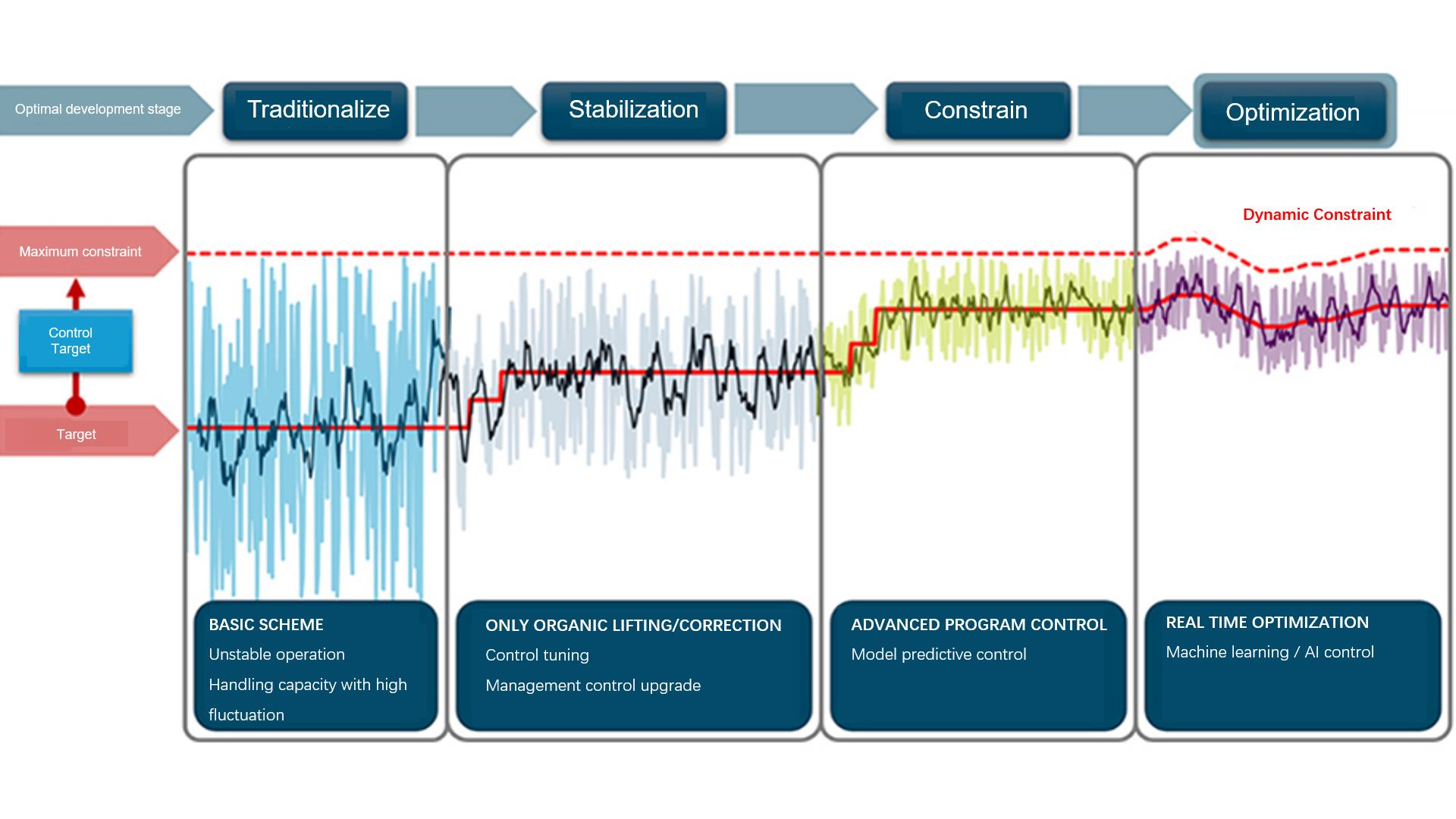

Intelligent control: The control system has multiple modules, including digital filters, potential field operation, programmable modules, classical closed-loop control (PI, PID) and freely programmable computing modules, as well as components of artificial intelligence (AI), including machine learning modules. Based on these modules, the system can establish various characteristic models of the parameters in the database, such as: real-time material level model, lining wear model, mill load model, collision point analysis model, etc., the system will be able to determine the best value of the mill operation through the analysis and verification of such models, so as to complete the control of the ball mill through the control module.

Through the monitoring and analysis of various parameters of the mill, the mill speed, steel ball volume, feed amount, etc. can be dynamically adjusted. The grinding & classification power AI intelligent optimization system integrates precise monitoring results into your grinding process, adjusts the mill feed, and stabilizes the grinding process while maintaining optimal fill levels, improving overall grinding efficiency and directly improving the production process.

It monitors:

1. Fill level height in the ball mill chamber;

2. Mill temperature;

3. Internal wear and tear;

4. Steel ball drop point;

It has the following advantages:

1. Easy installation;

2. Zero crosstalk;

3. Free band;

4. Virtually no maintenance required;

5. Process interface (4–20 mA)

6. Up to 3 sensors can be freely selected

7. Up to 16 product types

8. Industrial proof: IP65/Atex

9. Mounted on a ball mill (self-powered)

It makes beneficiation plant to:

1. Increase production;

2. Reduce ball mill maintenance costs;

3. Reduce ball mill energy consumption;

4. Improve and stabilize product quality;

It can be used in various industrial ball mills and the following industries:

1. Cement

2. Limestone

3. Coal

4. Gold

5. Iron

6. Alumina