Introduction

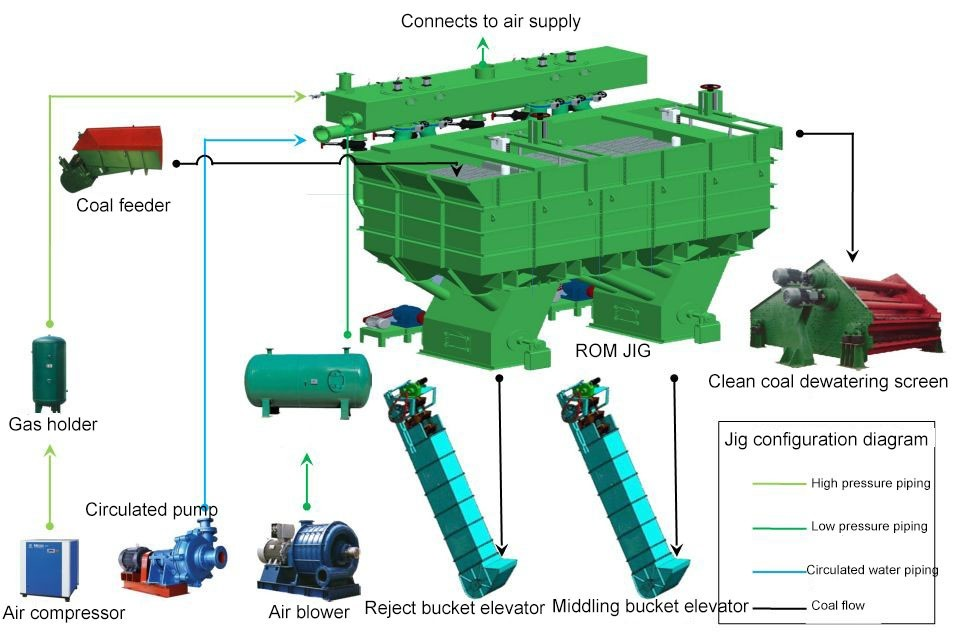

The SKT Jigging Machine, a flagship product from HOT Company, has earned widespread acclaim in the realm of coal sorting equipment. It has rapidly gained traction and is now widely adopted in coal processing plants. Real-world applications have demonstrated the SKT Jigging Machine's remarkable ability to boost processing capacity by up to 20% compared to conventional jigging machines, along with an impressive 3 to 5% improvement in separation efficiency. These enhancements translate into an annual revenue increase of over 3 million RMB per machine, underscoring its exceptional performance and value.

Key Features and Specifications

The SKT Jigging Machine is available in various structural configurations, including single-stage, two-stage, and three-stage, offering over twenty different specifications. It excels in sorting lump coal, fine coal, and ungraded raw coal, making it suitable for coal processing plants of varying scales. This machine stands out due to its outstanding features:

1. High sorting precision.

2. Large processing capacity.

3. Wide range of feed particle sizes.

4. High level of automation.

5. Simple operation.

6. Reliable performance.

7. Notable enhancements include:

Utilization of multi-chamber shared CNC conical slide valves or new type plate valves (single-plate or double-plate without backpressure) for improved valve performance, reducing faults, and lowering power consumption by 60-70%.

Adoption of a high-pressure air centralized purification and refueling device, enhancing the high-pressure air system's reliability and reducing maintenance requirements by 80%.

Incorporation of a single-chamber hopper-shaped modular body structure, simplifying installation and transportation while reducing the machine's load by nearly 30%.

Use of a new anti-clogging bed layer detection float and a stable discharge structure for precise control of discharge rates, ensuring product quality.

Implementation of fuzzy control algorithms to enhance bed layer control precision.

Integration of an intelligent control system with a PLC programmable controller, enabling single-machine automation and centralized control for the entire plant.

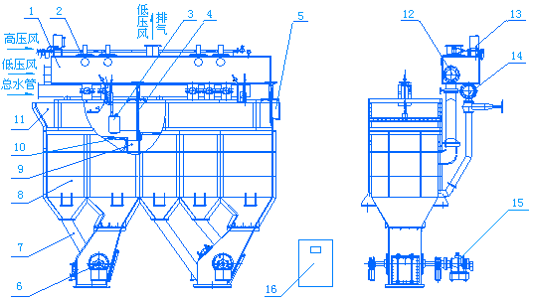

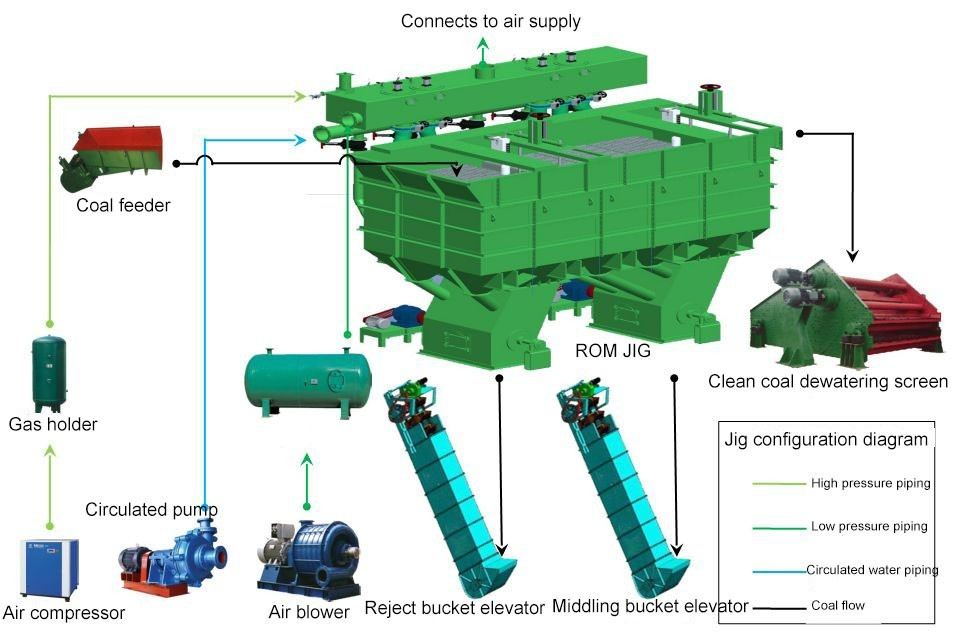

Structural Diagram of the SKT Jigging Machine

1 - Air blower 2 - Multi-chamber shared air valve 3 - Feeding end 4 - Single-chamber modular body 5 - Float device 6 - Dynamic overflow weir 7 - Sieve plate 8 - Discharge channel 9 - Transparent sieve material pipe 10 - Discharge wheel 11 - Overflow end 12 - Main air duct 13 - High-pressure air centralized purification and refueling device 14 - Main water duct 15 - Motor reducer

Non-Backpressure Soft Contact CNC Plate Air Valve

The performance of air valves is crucial for efficient material stratification. The SKT Jigging Machine employs state-of-the-art air valve technology to ensure optimal material sorting. Traditional electric rotary valves are slow to open and challenging to adjust. In response, the SKT Jigging Machine introduced CNC pneumatic plate valve technology, offering quick opening and flexible adjustment.

To address limitations, HOT further improved the valve by introducing CNC pneumatic slide valves that operate without backpressure and are resistant to damage from coal slurry and water. The latest innovation, the Non-Backpressure Soft Contact CNC Plate Air Valve, eliminates backpressure and impact, resulting in energy savings, extended durability, and high performance.

Multi-Frequency Pulsating Air Valve

The SKT Jigging Machine's air valves are equipped with PLC and touchscreen controls, enabling flexible adjustment of jigging systems. A multi-frequency pulsating function has been developed to cater to varying feed material properties. It allows independent adjustment of pulsation frequency and amplitude for gangue and middle-coal segments, optimizing sorting efficiency.

Multi-Chamber Shared Air Valve

HOT's multi-chamber shared air valve technology simplifies the system by reducing components, complexity, and maintenance requirements. It also significantly reduces high-pressure air consumption and the power demand of air compressors, enhancing operational convenience and saving costs.

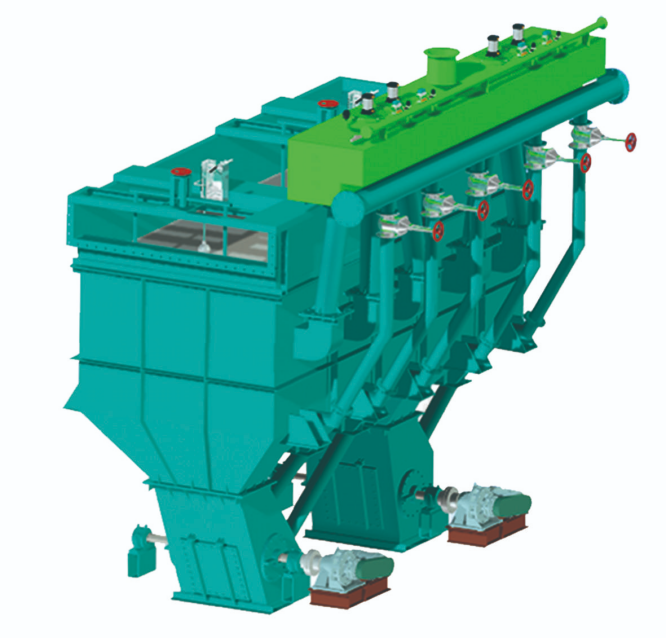

Single-Chamber Hopper-Shaped Modular Body

The innovative single-chamber hopper-shaped modular body structure improves pulsation efficiency, reduces energy loss, and streamlines transportation and installation. This design enhances the machine's overall performance and adaptability to varying coal qualities.

Non-Overflow Weir Hopper-Style Stable Discharge

Efficient material separation and discharge are vital for quality control and productivity. The SKT Jigging Machine employs the Non-Overflow Weir Hopper-Style Stable Discharge technology to achieve:

1. Precise and stable discharge.

2. Adjustable bed layer thickness.

3. Prevention of water surges.

4. Reduction of blockages by large particles.

5. Continuous, stable, and accurate control of discharge quantity.

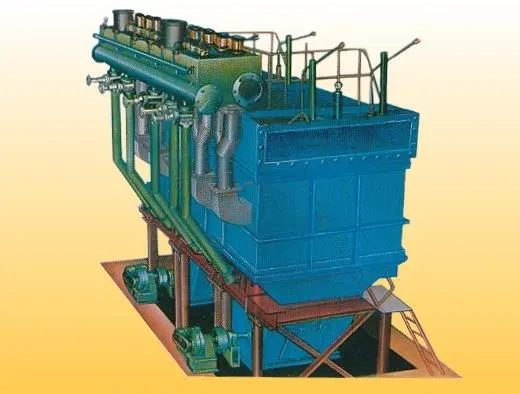

SKT CNC Resonance Jigging Machine

The SKT CNC Resonance Jigging Machine combines CNC pneumatic air valves and control systems to enhance sorting precision and productivity. It offers flexible CNC resonance, auxiliary jigging for different coal qualities, and conventional jigging, making it adaptable to various conditions and coal types.

SKT Intelligent Jigging Machine

The SKT Intelligent Jigging Machine features an intelligent control system with PLC and touchscreen, enabling automatic adjustment of operating parameters. It enhances control over bed thickness, feed rate, air and water volumes, and clean coal quality, leading to improved automation, higher productivity, and effective communication with central control systems.

Conclusion

The SKT Jigging Machine is a testament to innovation in coal sorting technology. Its exceptional performance, adaptability, and intelligent features make it a valuable asset for coal processing plants. As the industry evolves, HOT continues to pioneer advancements, ensuring the SKT Jigging Machine remains a cornerstone of efficient coal sorting for years to come.