1. Centrifuge Basket

1.1 Brief Introduction

Centrifuge basket is one of the key parts of centrifugal dehydration machine. It is a high speed rotating component. When the screen basket is not only subjected to vibration load, but also bear the serious impact of coal and water, the intensity and accuracy requirements are relatively high.

1.2 Materials of Centrifuge Basket

The main material of centrifuge basket includes low carbon steel, high manganese steel wire, stainless steel wire.

1.3 Advantages of Centrifuge Basket

Long service life, carrying capacity.

High screening efficiency.

Wide range of application, the application is stronger, and can be used for any type of vibrating screen machine.

High screening precision.

Low working noise, in line with national standards of environmental noise standards.

1.4 Technical Parameters

Model | Wide end diameter (mm) | Inner diameter (mm) | Half conical angle (°) | Maximum height (mm) | Sieve basket aperture (mm) |

HWZ-1300k | φ1312 | 13° | 700 | 0.5 | |

HZI-1000 | φ1015 | 13° | 554 | 0.5 | |

H-9 | φ919 | 20° | 475 | 0.5 | |

H-1200 | φ1200 | 450 | 0.3 | ||

H-800 | φ800 | 400 | 0.3 | ||

H-800 | φ320 | 90 | 0.3 | ||

H2-800 | φ801 | 290 | 0.3 |

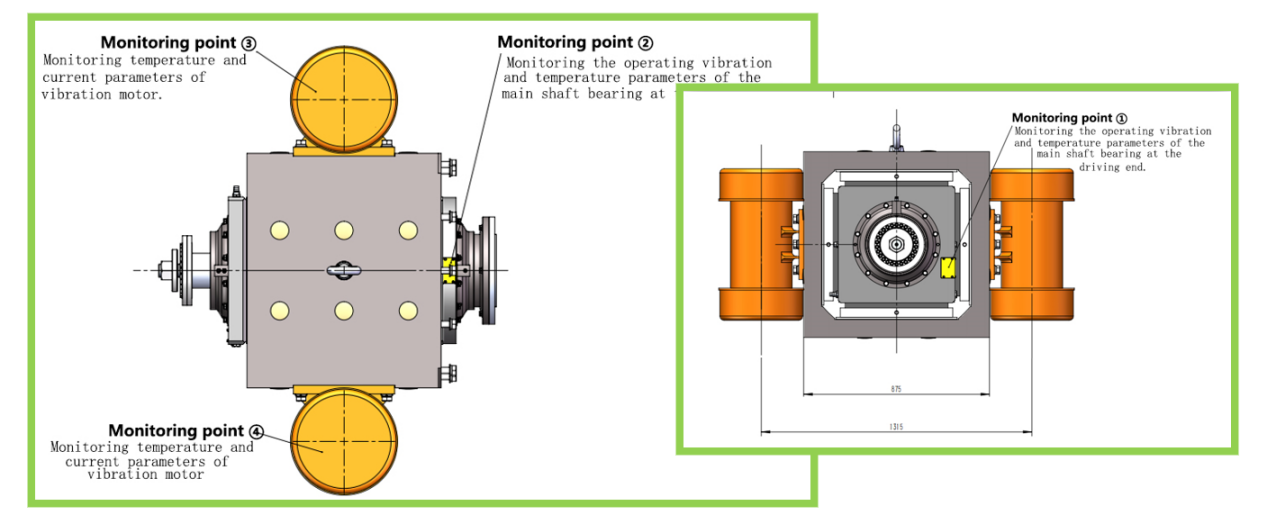

2. Cube

The cube is one of the core parts of the centrifuge, including bearings, bearing boxes, rubber plates and other parts. In daily production, due to the change of the feed quantity and production loss, it is necessary to replace it in time to avoid the loss caused by the shutdown.

The cube has two main functions:

1. Transfer vibration;

2. Support and fix the main shaft and screen blue;