1. Introduction of TPUStack SizerFine

TPUSTACK SIZERFINE high frequency vibrating is such equipment of which a single driving source drives multiple screen decks to vibrate simultaneously. The effective feeding width of tpustack sizerfine is the sum of multiple single screens.

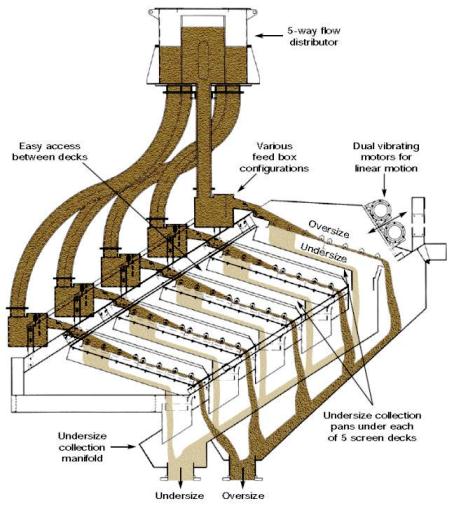

The processing capacity, screening efficiency and service life of tpustack sizerfine are similar to US Derrick stack sizer. In tpustack sizerfine up to five screen decks is positioned one above the other and operating in parallel. Each screen deck completes separating independently and has separate under-size and oversize collection pan. The under- size/oversize collection pans discharge to two common outlet respectively.

Two vibrating motors supply the vibratory action for all five of the screen decks. This high frequency vibratory motion is uniform throughout the entire width and length of each of the screen decks.

The use of dual vibrating motors creates a linear vibratory action by which an acceleration of 7.5G is discharged on particles.

Once the thin layer of slurry is introduced to the screen surface, the slurry is accelerated by the linear vibratory force.

This acceleration extends the effective fluidized zone of the mineral slurry, which enhances the separation over a larger area of screen surface.

The linear motion also conveys the screen oversize material out of the way of oncoming feed slurry so that more open screen area is available for the oncoming feed and classification efficiency is improved.

(1) Big screen area specific capacity

Practical production indicated when iron ore concentrate is treated:·

area specific capacity is 9-10 t/m2•h at screen aperture 0.15 mm

area specific capacity is 8-9 t/m2•h at screen aperture 0.10 mm

area specific capacity is 6-8 t/m2•h at screen aperture 0.08 mm

Area specific capacity of TPUstack sizerfine is 1.5-2 times of single Electromagnetic vibration sizer.

(2) Big floor area specific capacity

TPUstack sizerfine has greatest capacity at the same floor area coverage comparing to other vibrating fine sizers. One 5-deck stack sizer is able to replace 3-6 single deck vibrating fine sizers.

At the same capacity stack sizer saves 1/3 floor area.

(3) Patented repulping system improves the capacity and quality of screening

Spray water is directed at repulping troughs located between the two panels on each screen deck. Repulping system removes fines from oversize to maximum extent.

(4) One pair of motors provides a uniform high frequency linear motion throughout the entire volume of all screen decks. This cannot be realized by electromagnetic vibrating sizer.

(5) Screen frame surfaced by polyurethane, extending machine life significantly

Surfaced by special modified polyurethane abrasion-resistant compound imported from US; not only anticorrosive but also abrasion-resistant. The abrasion resistance is 10-15 times of carbon steel. Life of Hot stack sizer is +8 years.

(6) Low energy consumption (single machine power draw 4.5kW)

No | Solid Feed Flow Rate (t/h) | Undersize Fineness (-200 mesh) | Classification Efficiency | Sand Returning Ratio | |||

1 | 32 | 17.81% | 66.00% | 24.00% | 87.00% | 87.88% | 50% |

2 | 67.8 | 32.78% | 48.00% | 13.00% | 76.00% | 87.96% | 80% |

3 | 87.3 | 39.43% | 45.00% | 13.00% | 70.00% | 87.33% | 78% |

4 | 78.9 | 36.70% | 51.00% | 17.00% | 73.00% | 86.90% | 64.7% |

5 | 112.4 | 46.80% | 46.00% | 18.00% | 73.00% | 80.79% | 96.4% |

6 | 160.5 | 43.31% | 47.00% | 21.00% | 78.00% | 75.70% | 119% |

7 | 100 | 44.00% | 60.00% | 21.00% | 79.00% | 88.53% | 48.7% |

8 | 102.3 | 26.80% | 76.00% | 44.00% | 92.00% | 80.70% | 50% |

9 | 91.45 | 37.75% | 54.33% | 21.00% | 77.20% | 85.37% | 69.63% |

Please note that:

All above equipment we offering are just basic models; 2.MES can produce the specific machinery according to clients' requirements

Contact us:

Mr.Kurt

Email: jiangmy@hot-mining.com