Laser-Induced Breakdown Spectroscopy (LIBS) or Laser-Induced Plasma Spectroscopy (LIPS) is a rapid chemical analysis technology that uses a short laser pulse to create micro plasma on a sample surface. This analytical technique offers many compelling advantages compared to other elemental analysis techniques.

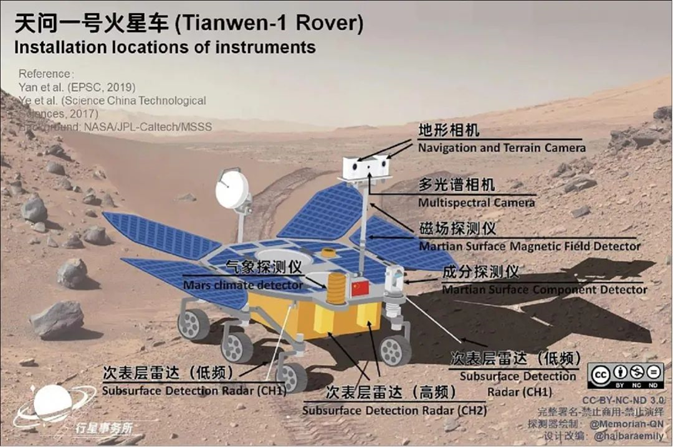

The surface composition detector of the Zhurong rover includes Laser-Induced Breakdown Spectroscopy (LIBS) and Short-Wave Infrared Spectroscopy.

Let's start with the latter. "Spectroscopic" detection is a commonly used remote sensing method. Different materials have different characteristics in reflecting light, and the result is that the reflection spectrum image containing a particular substance will show prominent absorption bands in certain specific bands. This is the "fingerprint" that scientists search for when looking for a particular sense in outer space that they cannot physically reach.

Whether it is a spectrometer carried by an orbiter or a spectrometer taken by a rover, essentially, they both detect which minerals are contained on the planet's surface and what their distribution is by observing the features of the reflected spectrum of the target area— the difference is only in the detection frequency band and resolution of different spectrometers, and the corresponding detected material composition may also differ.

The Short-Wave Infrared Spectroscopy is a detection band of this spectrometer in the short-wave infrared band (0.85-2.4 μm).

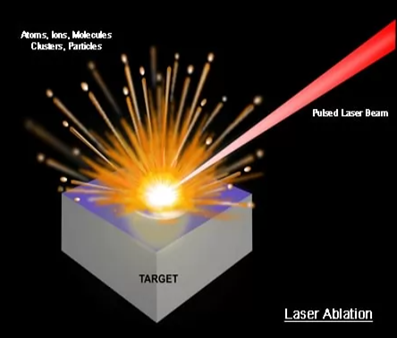

The LIBS is even more impressive: by emitting high-energy laser pulses to the target object, it detects the characteristic emission spectrum during the cooling process of the ablation-excited plasma. It then remotely detects the basic composition information of the target object. Simply put, this is a "laser cannon."

The LIBS of the Zhurong rover can detect more than ten elements in the target object, including silicon, aluminum, iron, magnesium, calcium, sodium, oxygen, carbon, hydrogen, manganese, titanium, and sulfur. This is also China's first time using this technology for deep space exploration. Before this, NASA's ChemCam and SuperCam carried by the Mars rover verified the scientific value of this "high-energy" technology on Mars.

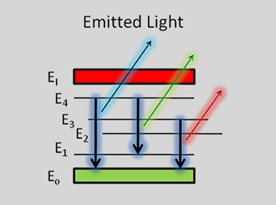

How does the LIBS laser-induced breakdown work? Spectral analysis can reveal the chemical composition of planets and stars tens of thousands of light-years away. Essentially, this is based on the unique characteristic that each element has a distinctive absorption spectrum. This principle can also be applied in reverse. When electrons return from the "higher" energy level to the "lower" energy level, they release the energy they previously absorbed, which means the previously absorbed specific wavelength of light will be rereleased, changing from an "absorption" spectrum to an "emission" spectrum. The most common example in life is the different colored flames produced when metals burn: copper produces a blue flame, lithium produces a red flame, calcium produces an orange flame, sodium produces a yellow flame, and barium produces a green flame. Each element has its unique emission spectrum.

Therefore, in theory, to analyze the chemical composition of a compound, one only needs to ignite the combination and explore the spectrum of its flame. But, of course, without even considering that some compounds' ignition points and even melting points can be very high, in most cases, people want to complete the analysis without destroying the sample itself. This is where the laser comes in. Compared with the "violent" behavior of collecting the spectrum of the flame of the plasma by igniting the compound as a whole, the laser, which also originated from quantum mechanics, has the unique advantage of being able to release enormous energy in a short time and small range, allowing a small part of the compound to become plasma without damaging the overall sample. If the shutter of the spectrometer is fast enough, it can capture the light emitted by the plasma after the trace sample is ionized in a short time. On the premise of not damaging the sample, it can construct an emission spectrum and analyze the specific composition of the compound sample.

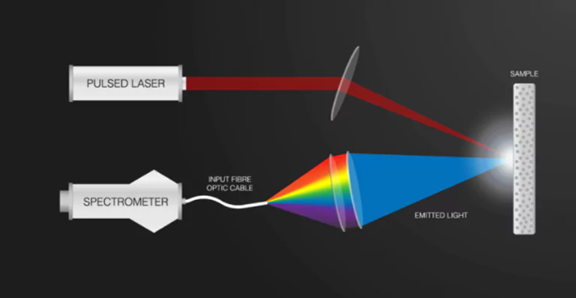

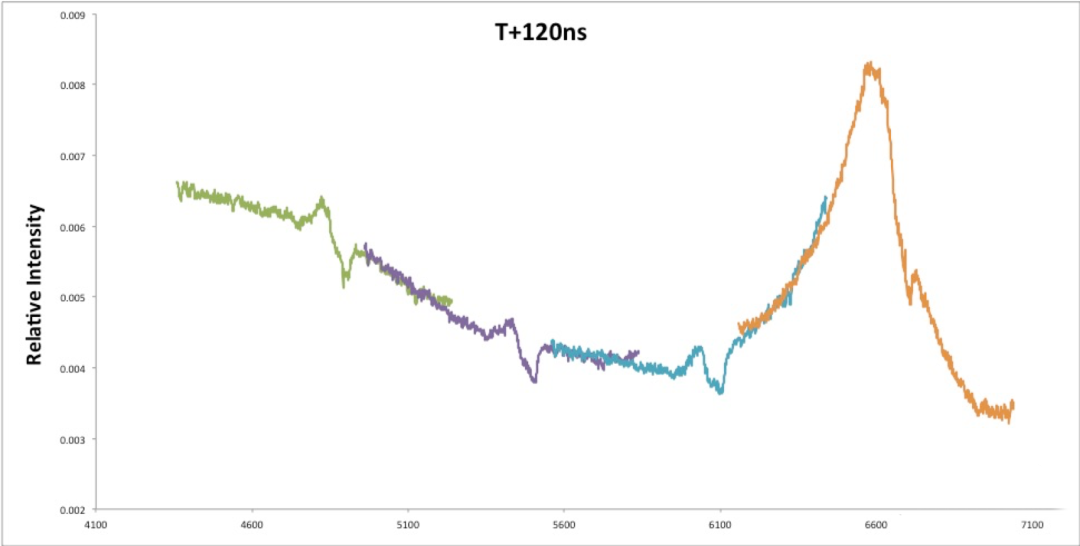

Specifically, LIBS focuses on a tiny area on the sample's surface and rapidly emits a pulsed laser with a temperature exceeding 30,000 degrees Celsius, causing the sample to ionize to about one picogram (10^-12 grams) to 1 nanogram (10^-9 grams). As a result, chemical bonds quickly break down, and electrons within the elements are instantly excited to higher orbits. The plasma then expands supersonically and rapidly cools after 10 microseconds (10^-6 seconds), and the excited electrons return to lower orbits to release the light of specific wavelengths. The spectrometer then scatters the light at different wavelengths to analyze the chemical composition. Taking water, the most commonly used substance in nature, as an example, the water spectrum of LIBS is as follows:

There is a prominent peak at a wavelength of about 660 nanometers, called the Balmer series alpha line, which corresponds to the light released by the electron of a hydrogen atom returning from n=3 to n=2. The accurate wavelength is 656.3 nanometers, corresponding to visible red light. The peak is much broader than almost a single line for pure hydrogen gas. The peak position is also shifted because the plasma generated has a concise duration and is easily affected by external factors such as refraction in water. Therefore, for samples with complex components, LIBS often requires hundreds or even thousands of laser pulses to obtain a large amount of spectral data for comprehensive analysis to reduce the impact of external factors on single sampling. Fortunately, even with 1000 laser pulses, only about one microgram of mass is lost, and the sampling time is short, which will not harm the sample or actual collection.

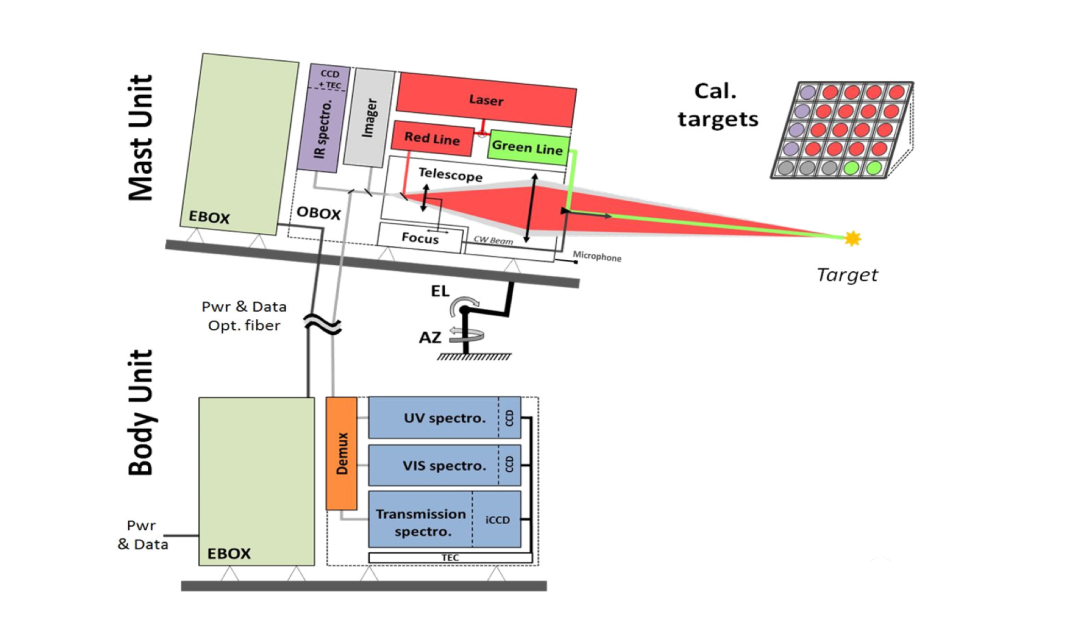

Because of its non-contact sample composition analysis feature, LIBS is particularly suitable for use in outer space explorers. For example, ChemCam, which uses LIBS technology, followed the Curiosity Mars rover and landed on the surface of Mars in 2012. The "eye" on the "head" of the Curiosity rover is the ChemCam laser emitter, which emits a 5-nanosecond pulsed infrared laser to ionize the Martian soil within a range of 7 meters. The 110-millimeter lens camera under the laser emitter then transmits the light emitted by the plasma state of the Martian soil to the spectrometer inside the vehicle through optical fibers, and the spectrometer scatters the light onto the spectrum from 240 nanometers to 820 nanometers.

Now, let's turn to the application to mineral processing.

In response to the need for fast and real-time quantitative detection of multiple elements, exceptionally light factors (Z<11), involved in different products in different industries, this cutting-edge technology relies on the green technology of laser-induced breakdown spectroscopy to solve the technical problem of rapid detection of all elements, and develop intelligent spectroscopy technology for quick and quantitative detection of all elements, thus meeting the product requirements of key sensor links in the field of intelligent manufacturing. As a result, it will be widely used in coal, soil, metallurgy, and other areas, filling the technical gap of missing sensors.

Based on the theory and technology of micro-area enhanced spectroscopy, HOT has developed an online coal quality analyzer. Using the approach of large dielectric constant and the technology of discharge-enhanced spectroscopy to partially suppress the matrix effect, the spectral intensity has increased by nearly ten times. The spectral stability has increased by 57%, achieving high-precision spectral measurement, solving the problems of low accuracy and poor stability in coal quality testing, and then completing the industrial application of a high-stability all-element rapid detection spectroscopy system establishing an industrial base. This system can conduct a high-precision and quick quantitative analysis of more than 50 elements, including C, H, N, and S, and provide four significant indicators of coal calorific value, ash content, volatile content, and moisture content.

Application areas:

1.Online quality management of industrial enterprises;

2.Energy-saving and consumption reduction of coal-fired power enterprises;

3.Combustion control;

4.Quality identification;

5.Rapid monitoring of elements in the soil industry;

6.Rapid screening of beneficial and harmful elements of bulk commodities by customs.

HOT LIPS Element Analyzer has provided a green online coal quality detection solution for coal enterprises, which has been applied in several coal preparation plants in Guizhou and several power plants in Shandong. In the application scenario of power plants, the last technical link of combustion control of coal-fired power enterprises is opened up. As a result, each unit can save millions of money annually on average. The total energy saving of several installed units is more than tens of millions of cost, significantly reducing the boiler accident rate caused by improper element detection and changing the rough operation mode of the coal-fired power industry.

Application Prospects:

The market potential for rapid detection of all elements in the mining industry is enormous, covering coal quality testing, mineral elements, and other sectors, with a market capacity of nearly 100 billion yuan. However, traditional element detection technology has a low sampling rate, and the sample preparation and processing process could be more convenient. For example, coal quality analysis in coal preparation plants and coal-fired power plants takes 4-6 hours, which cannot meet the real-time coal blending, fine coal combustion control, energy-saving, efficiency-enhancing, and other large-scale environmental needs.

Furthermore, existing real-time analysis technology is based on radioactive methods such as neutron activation technology, which the industry opposes due to its radioactive nature, and requires strict safety and environmental impact assessments. On the other hand, the all-element rapid detection instrument combines LIPS technology's real-time and green advantages. On this basis, innovatively introduces the spectral enhancement method, significantly improving the detection accuracy and breaking through the industrialization problem of LIPS technology, truly achieving fast and accurate detection. Therefore, our product has unique technical advantages, solves the detection industry's pain points, meets the detection market's needs, and has broad development prospects.

After the equipment is put into operation, the accuracy of all element detection has reached the industry standard. The Yueliangtian Coal Preparation Plant in Guizhou, combined with the Dynamic Dense Medium Controlling System, produces about 8,000 tons of clean coal annually, with an economic benefit of up to CNY 15 million annually.

Contact us

Email: sales@hot-mining.com

Linkedin: Click here