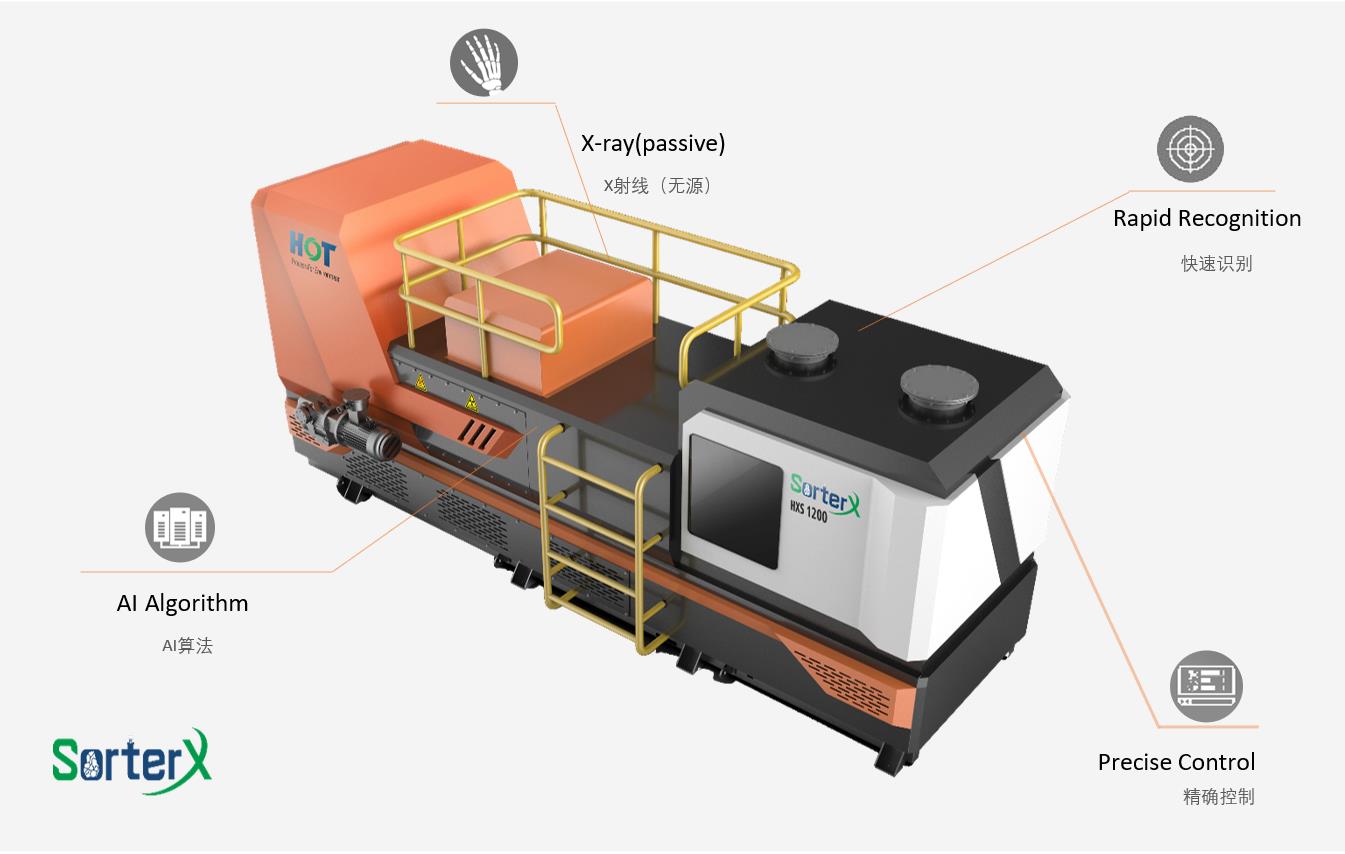

XRT Intelligent Sorter: The XRT sorter is an automated sorting machine that uses advanced imaging and artificial intelligence (AI) technologies. It employs an X-ray imaging system to analyze and identify coal and gangue (impurities) based on material characteristics. High-pressure air jets then selectively remove the gangue, achieving precise, particle-level sorting.

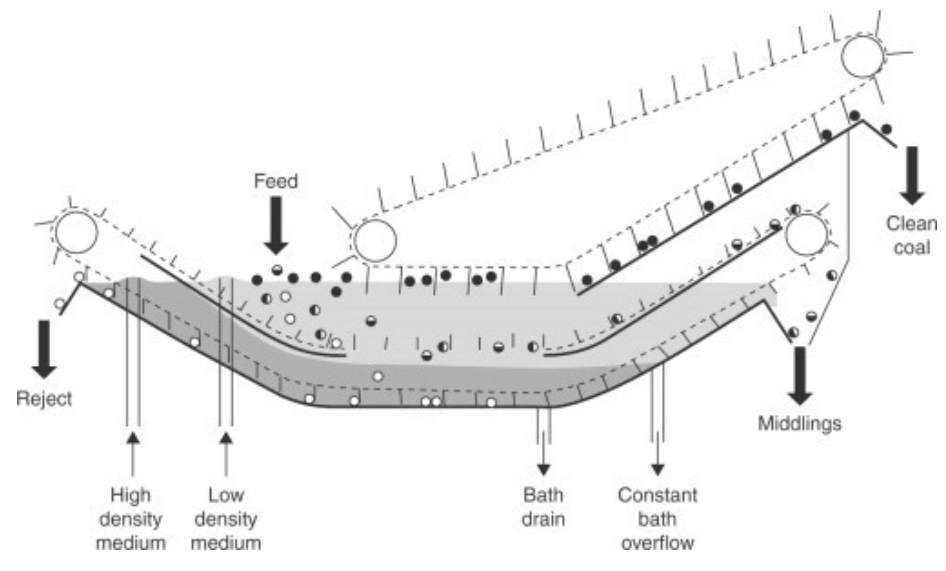

DSM Bath: This traditional method operates on Archimedes' principle, sorting materials within a gravity field. Coal that is less dense than the medium floats and is directed to overflow as clean coal. Denser gangue sinks and is removed by a slow-moving chain scraper. The DSM Bath's sorting accuracy, however, can be affected by the density of the suspension, water flow, and settings of various machine components.

XRT Intelligent Sorter:

o Processing Size Range: Capable of handling coal sizes from 10-300 mm.

o Separation Accuracy: With a gangue removal rate over 95%, the presence of gangue in coal is kept below 2%.

o Processing Capacity: Manages up to 300 tons per hour, accommodating a wide variety of particle sizes.

o High-Level Automation: Self-detection for faults minimizes labor requirements, contributing to cost efficiency.

Dense Medium Bath:

o Processing Size Range: Handles coal sizes from 6-300 mm.

o Adaptability: Strongly resistant to fluctuations in coal quality, making it suitable for varying inputs.

o Operation Cost: Low operational costs and a wide range of gangue discharge capabilities.

1)Simplified Structure and Process: Unlike traditional systems, the XRT sorter requires no water, filtration, or dense media recovery systems. This simplifies the setup, eliminates the need for complex piping, and reduces maintenance requirements.

2)Enhanced Sorting Accuracy: By using AI and precise data modeling, the XRT sorter identifies and separates coal and gangue with a high degree of accuracy, even at varying particle sizes. This accuracy surpasses traditional sorting methods, enabling cleaner separation.

3)Lower Operational Costs: The XRT system uses X-ray identification and high-pressure air jets, keeping energy consumption low and eliminating the need for water and dense media. Compared to DSM Bath’s higher energy and setup costs, this offers substantial cost savings.

4)Reduced Labor Needs: With advanced automation, the XRT sorter reduces the need for continuous manual monitoring. In contrast, DSM Bath still requires labor for handling large particle sizes, making XRT safer and less labor-intensive.

5)Minimized Environmental Impact: Traditional coal washing processes produce waste slime, which contributes to environmental pollution. The XRT sorter, however, requires no water, thus eliminating slime production. Additionally, the high-calorific coal produced by the XRT sorter can be sold directly, further reducing environmental impacts.

The XRT Intelligent Sorter offers numerous advantages over the DSM Bath, including automation, water conservation, reduced operational costs, and increased sorting accuracy. It enhances coal utilization efficiency, aligns with sustainable practices, and adapts to the future direction of the coal industry. Through advanced technology and eco-friendly operations, the XRT sorter represents a step forward in coal preparation technology.