1. Equipment Optimization & Maintenance (Maintenance is not a cost but an investment)

Maintenance is not an expenditure—it is an investment that enables equipment to become “predictive and perceptive.”

Predictive Maintenance System Monitoring

Prevention Over Repair

Establish predictive and preventive maintenance systems to shift from reactive repairs to proactive prevention.

Through real-time monitoring and data analytics, unplanned downtime can be reduced and equipment availability improved.

Many mines today have adopted PHM (Prognostics and Health Management)–based intelligent monitoring technologies to identify early-stage failure trends, enabling scientific maintenance and lifecycle management.

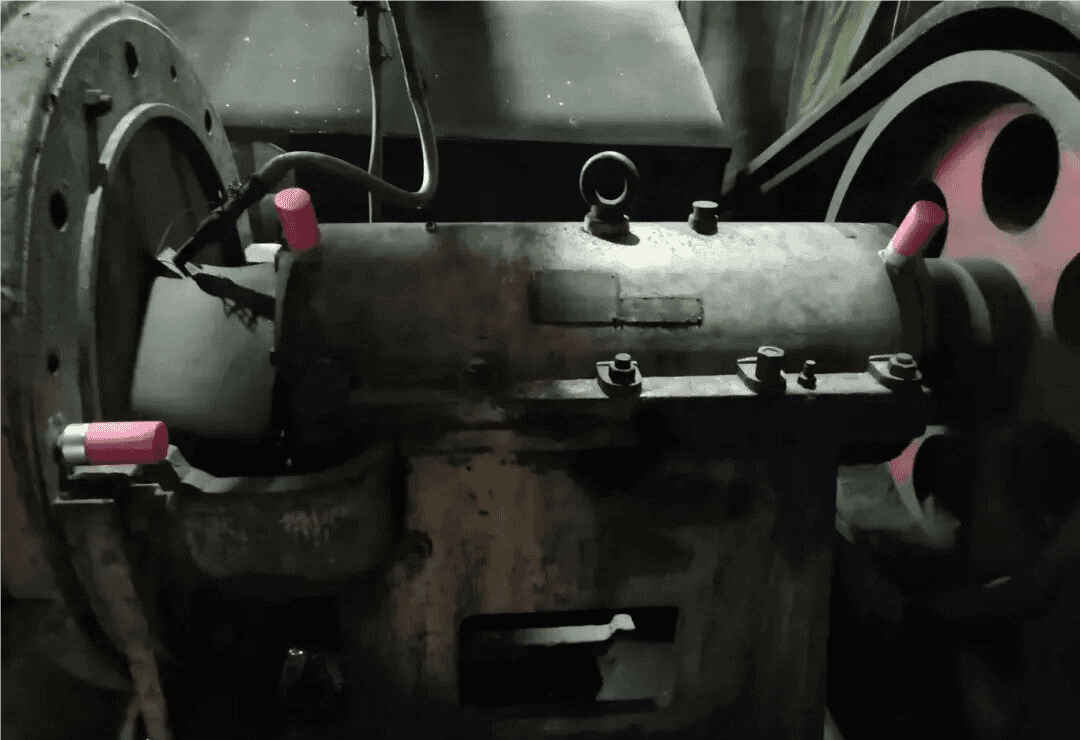

Centrifuge PHM Monitoring System Interface

On-site PHM Sensor Installation

Increase Equipment Utilization: Focus on extending MTBF (Mean Time Between Failures) and reducing MTTR (Mean Time To Repair) to comprehensively boost the performance of critical equipment.

Rational Equipment Fleet Sizing: Configure hauling and loading fleets scientifically based on production capacity and operational needs, avoiding both “oversized equipment for small tasks” and capacity shortfalls.

Tire Management as a Key Cost Item:Tires represent a high proportion of operating costs; therefore, maintaining haul-road conditions and monitoring tire pressure are essential to prolong tire life and reduce replacement frequency.

2. Core Process Efficiency (Focus on the Four Major Cost Drivers)

Mining costs are primarily concentrated in drilling, blasting, loading, and hauling.

Drill & Blast Optimization

Reduce over-break and over-fragmentation: optimize blast design to achieve ideal fragmentation and reduce downstream crushing energy consumption.

Rational powder factor: control explosive consumption to balance blasting costs with downstream processing expenses.

Loading & Hauling Efficiency Management

Road quality: Maintain high-quality haul roads to reduce rolling resistance, save fuel, and extend tire life.

Loading match: Ensure capacity alignment between loading equipment and haul trucks to minimize waiting times and increase cycle counts.

Fuel management: Establish fuel-monitoring systems to track fuel consumption per ton of ore, enabling energy-use visibility and optimization.

As electric-drive technology advances, battery-electric mine trucks have become a powerful tool for reducing transport-related costs. Compared with diesel trucks, electric mine trucks offer significant advantages in energy consumption, maintenance costs, and environmental performance.

Combined with intelligent dispatch systems, they deliver more efficient haul cycles and stable energy management.

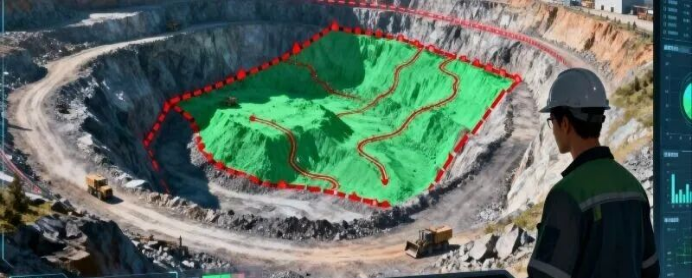

3. Planning and Quality Control (Pursuing "Value Maximization" Rather Than "Output Maximization")

Strictly Execute the Mine Plan

Ensure daily operations strictly follow the overall mine plan and production schedule, avoiding misalignment with orebody geometry or excessive production that leads to resource waste.

Optimize Cut-off Grade

Regularly evaluate and dynamically adjust the cut-off grade.

Low-grade ore has high processing cost and low profitability; when metal prices decline, the cut-off grade should be increased to focus on high-margin production zones.

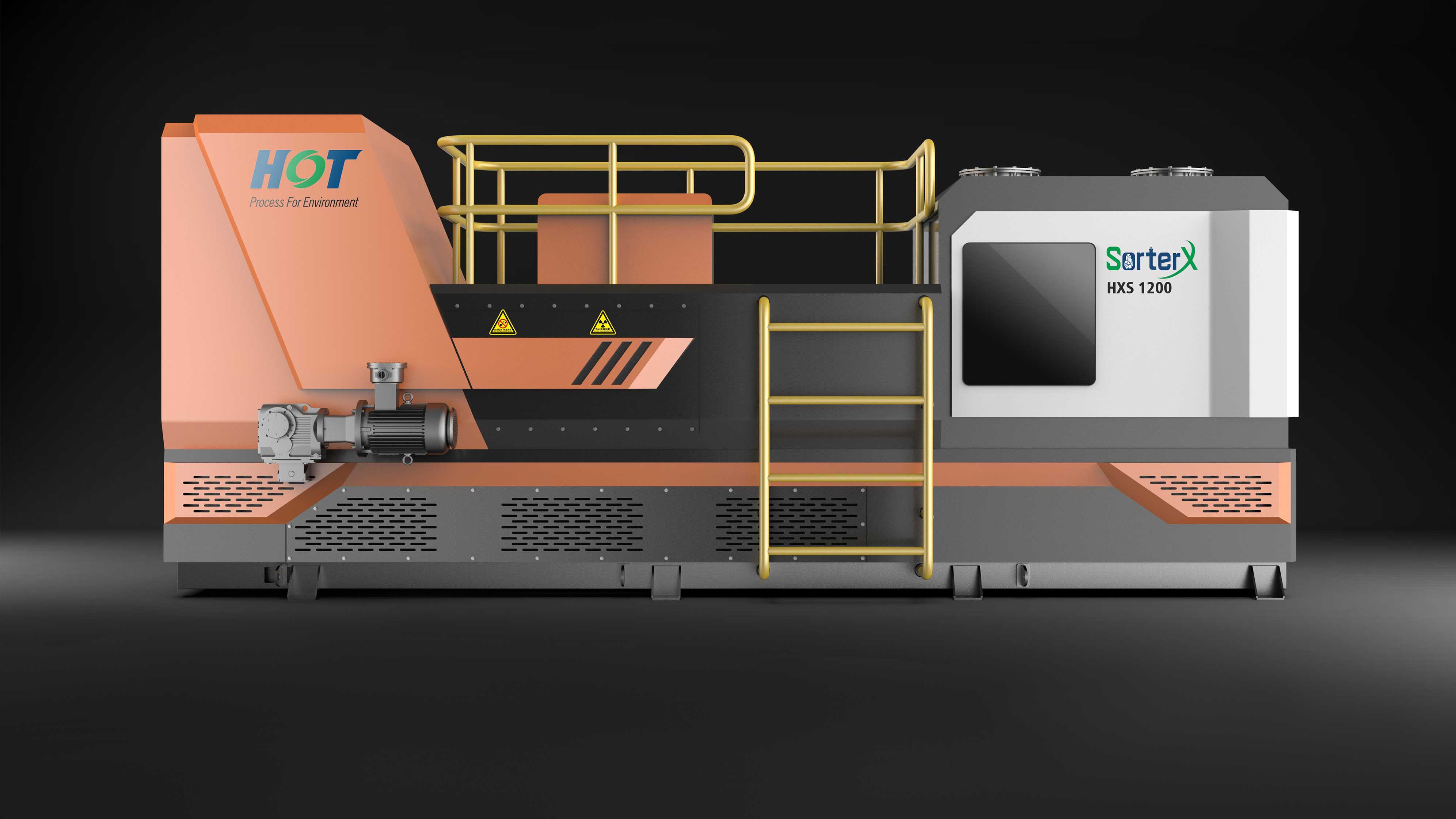

XRT intelligent ore-sorting technology can remove waste rock at the ROM (run-of-mine) stage, effectively increasing the cut-off grade and improving economic returns.

Grade Control Management

Through accurate sampling and strict quality control, reduce ore dilution and loss, ensuring stable feed quality and optimal economic performance.

LIBS online elemental analysis technology enables real-time detection of ore composition, supporting rapid on-site adjustments to process parameters and reducing cost fluctuations caused by feed variability.

LIBS On-site Operation

4. Supply Chain and Inventory (Leveraging Procurement Effects)

Centralized Procurement to Maximize Bargaining Power

Consolidate procurement across different mines or departments to build scale advantages with key suppliers and secure volume discounts and long-term cooperation benefits.

Optimize Spare-Parts Inventory

Avoid excess inventory tying up capital.

Using equipment maintenance cycles and consumption patterns, implement intelligent inventory-management systems to achieve "available when needed without overstocking."

Automated Logistics Sorting System

Conclusion: Let Intelligence Become the Invisible Lever for Cost Control

Mining cost control is not about simple cost-cutting—it is the outcome of systematic optimization.

From equipment and processes to planning and procurement, incremental improvements at every stage can yield significant economic gains.

In the era of digitalization and intelligent mining, the “golden rules” are being redefined.

Intelligent maintenance, precision ore sorting, real-time analysis, and green transportation are quietly becoming new drivers of cost reduction and efficiency enhancement in modern mines.