1. Filter Press

The filter pressing of concentrate or tailings is an important link in the production of concentrator, and the filter press plays a pivotal role in this processing link. As the last ring of the concentrator, the filter press system restricts the washing capacity of the whole system. Therefore, the efficient operation of the filter press system is particularly important. HOT is a leading supplier of filter presses with complete models and excellent performance in China. The features of HOT filter press are automatic feeding, automatic end of feeding, automatic queuing unloading, system safety locking, and intelligent monitoring of filter press status.

2. HOT's Filter Press Advantages:

Rapid separation times increase processing efficiency

Improved safety an d lower operating costs

Reduced component stress, improved safety and lower operating costs:

Automate your press’ internal cleaning

Holistic service and maintenance support

3. Types

3.1 Membrane Filter Press

·Application: Membrane Filter Press is mainly used in mining, paper making, coking, medicine, food, chemical and other industries.

·Features: feeding pressure: 0-16MPa; filtering area: 30-1000m

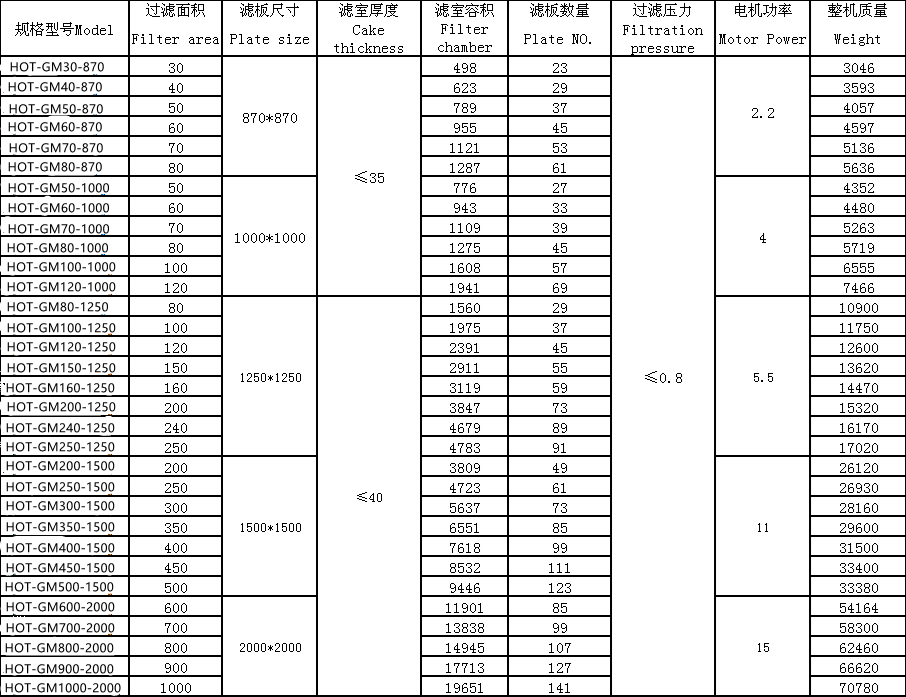

·Model parameter table

3.2 Chamber Filter Plate

·Application: widely used in metallurgy, chemical industry, printing and dyeing, ceramics, food, medicine, mining, coal washing and other industries

·Features: feed pressure: 0-0.6MPa Filter area: 30-1000m

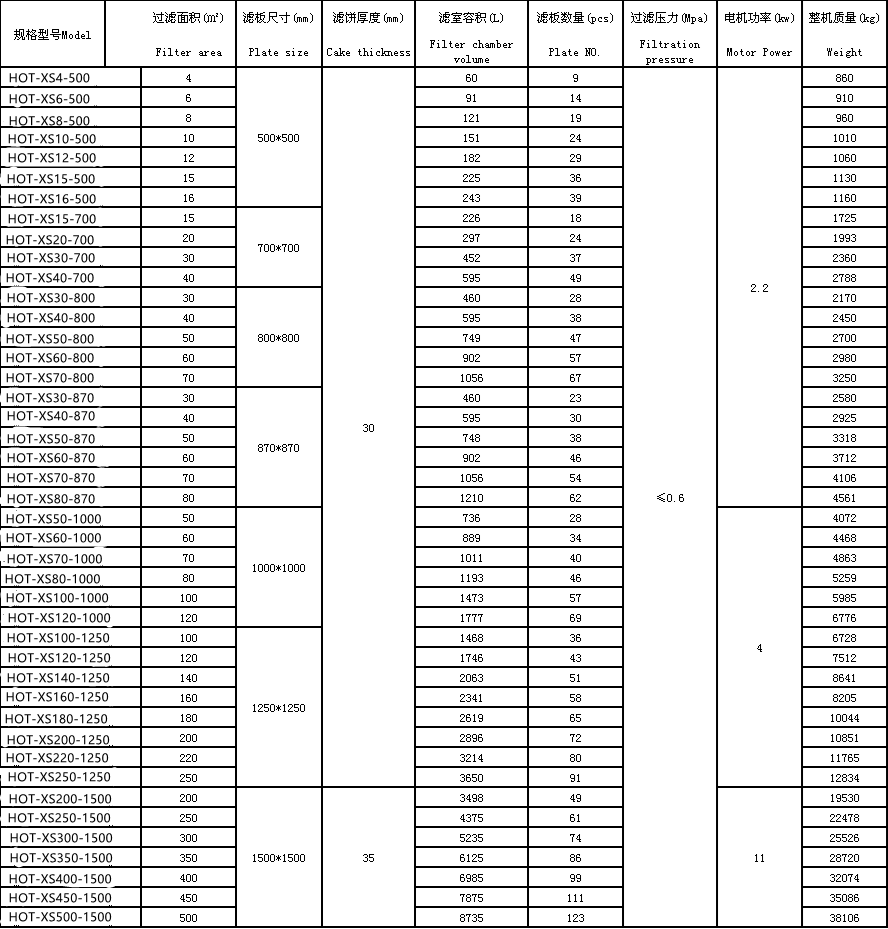

·Model parameter table

3.3 Plate and Frame Filter Press

·Applications: chemical industry, dyestuff, petroleum, ceramics, pharmacy, sugar making, starch, paint, metallurgy, sewage treatment and other products.

·Features: The plate and frame filter press is applicable to suspensions with high compressibility of filtering slag or nearly incompressible. The plate frame is usually square, the inner side length of the filter frame is 200~2000mm, the frame thickness is 16~80mm, and the filtering area is 1~1200m. The plate and frame shall be compressed by manual screw, electric screw and hydraulic pressure. The plates and frames are made of wood, cast iron, cast steel, stainless steel, polypropylene and rubber.

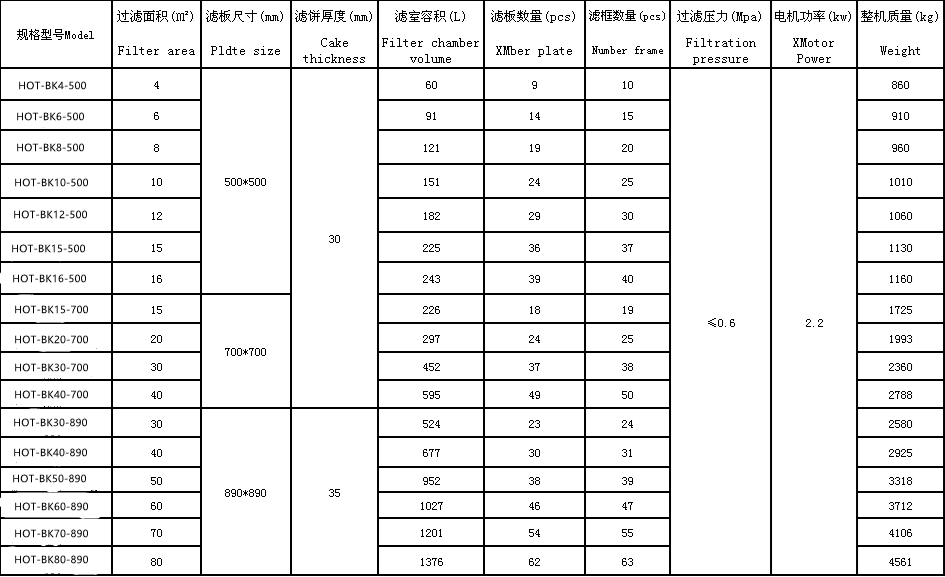

·Model parameter table

3.4 Sludge Pressure Filter

·Application: It is widely used for sludge dewatering treatment in urban domestic sewage, textile printing and dyeing, electroplating, paper making, leather, brewing, food processing, coal washing, petrochemical, chemical, metallurgical, pharmaceutical, ceramic and other industries, as well as for solid separation or liquid leaching processes in industrial production.

·Features: The series belt filter press features compact structure, novel style, convenient operation and management, large processing capacity, and low water content of filter cake.

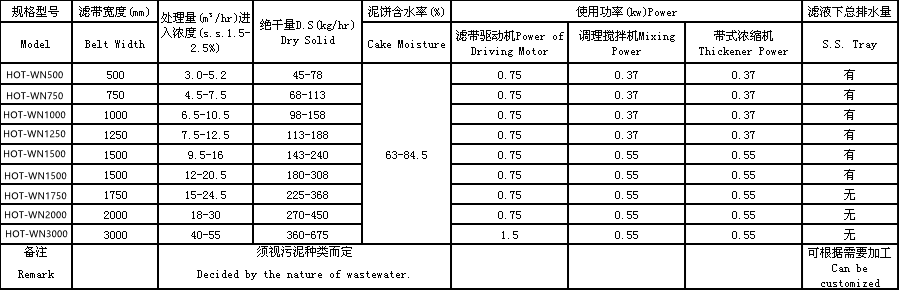

·Model parameter table

4. HOT's Intelligent Filter Press

At present, the filter press used in each concentrator is basically a single machine automation equipment, which can only be operated through the on-site control cabinet, and many production links rely on the observation and judgment of the post personnel, so the work intensity is high, the staff demand is large, the production efficiency and the slime dewatering index cannot be guaranteed. HOT has carried out the research and application of intelligent filter press system in view of this situation, and has carried out research and implementation from many aspects, such as automatic feeding, automatic end of feeding, automatic queuing unloading, system safety locking, filter press status monitoring system, filter press video monitoring and filtrate particulate matter monitoring system, to enhance the intelligent level of each link, improve work efficiency, reduce the demand of post personnel, and reduce the labor intensity of the post.

The following objectives can be achieved:

·The central control room can remotely control the start and stop of the filter press, automatic feeding, automatic pump stop and other functions;

·The filter press can automatically feed, judge the end of feeding, and intelligently queue for unloading and discharging;

·The linkage between the filter press and the centralized control system realizes the intelligent control of the filter press and the automatic queuing of multiple filter presses;

·Monitoring and notification of incomplete discharge of filter press, damage of filter cloth, deviation of filter plate, etc.

5. Applications

Machines involving industrial filter presses can be used in the following industries:

Chemical industry

Pharmaceutical

Sewage treatment

Mining

Catering

Chemicals

Oil

Beverages

Cement

Papermaking

......

The working principle of these industries is liquid-solid conversion. In this process, most suspended solid particles will not be completely dissolved. Filtration is necessary to separate these solid particles and make the liquid transparent for further processing.

Contact:

Tiffany Chen

+86 18282103350

The traditional filter press production mainly relies on manual operation, and there are two main problems: ① the degree of intelligence is limited, and the degree of pressing needs to be checked and judged manually, the work efficiency is low, and the product moisture cannot be guaranteed; ② Manual on-site operation may cause damage to the hydraulic system or personal injury caused by pressure filter spray. The intelligent filter press control technology can remotely control and switch the manual/automatic mode, release, press, feed and other signal commands of the filter press by monitoring the status information of the filter press in the system in real time, including the release, press, feed and other process status information, and realize the automatic feeding and queuing unloading functions of the filter press, which can replace the traditional manual operation.

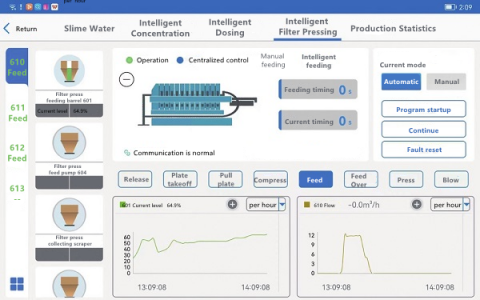

The intelligent filter press control technology includes functions such as remote monitoring at the mobile end, automatic feeding, automatic end of feeding, queuing and unloading, automatic start and stop of transfer equipment, filter press production locking and filter press production statistics. The main configuration includes flow meter (ultrasonic level gauge), automatic control valve and filter press signal communication module. The technology is equipped with control units such as centralized monitoring of the moving end of each filter press, monitoring of the end time of the filter press feeding by operating parameters, and automatic control of the filter press production process. The control interface of the intelligent pressure filtration detection system is shown in the figure.

The functions of each control unit of the intelligent pressure filtration detection system are as follows:

1、Centralized monitoring at the mobile end of each filter press will display the information of multiple filter presses and relevant main equipment in the intelligent filter press detection system on the intelligent operation terminal by adding mobile terminals and wireless network systems, break the information island between the filter press and the filter press, and between the filter press and the relevant auxiliary equipment of the intelligent filter press detection system, and realize the unified and centralized supervision of all equipment and relevant information in the intelligent filter press detection system, Reduce the labor intensity of post inspectors and facilitate production supervision.

2、The automatic control of the production process of the filter press has realized the automatic control of many links of the filter press system from feeding to the filter press feeding, the filter press unloading, the production locking and so on through the intelligent design and transformation, basically eliminating the manual intervention, realizing the full automatic control of production, and combining the historical production data to realize the accurate judgment of each link. Intelligent filter press control technology realizes automatic feeding, automatic judgment of the end of feeding, automatic queuing and unloading, filter press production statistics, coal slurry transportation system locking, automatic switching of underflow pump and other functions through each control unit, realizing the unmanned operation of the whole process of filter press production, improving the working efficiency of the filter press by more than 15%, and realizing unattended operation on site.