With the rapid development of the mining industry, the underground loaders of trackless mining equipment in China's non coal underground mines increase by about 15% every year. At present, there are thousands of underground loaders in domestic underground mines, which are basically operated manually. With the attention of governments at all levels to occupational health and safety, underground mining has evolved from the original manual mining to automation and intelligence after mechanization. It is these developments that make this industry, which used to be labor-intensive and high-risk, easy and safe. The automation and intelligent development of underground loaders will make "unmanned mine" a reality. The development of underground loader automation has been the fourth generation, the following will be introduced from the development process and future development trend.

With the progress of society and the development of science and technology, people pay more and more attention to health and environment, safety has become the top priority of mechanical equipment. In order to protect the safety of operators and equipment, reduce mining costs and improve production efficiency, mining equipment has been transformed from mechanization to automation. Some foreign mines have achieved or partially achieved the goal of automation. Its development has gone through manual control, remote control, remote control, semi autonomous control and autonomous control, as shown in Table 1.

At present, the underground mining equipment basically adopts manual control (as shown in Figure 1), one machine and one person, which has the advantages of simple operation and low cost. Due to the manual operation of these equipment, the labor intensity of workers is high, and the efficiency is low, especially the bad working conditions such as rock fall, vehicle vibration, dust and harmful gas emitted by diesel engine, which pose a direct threat and harm to the safety and occupational health of drivers. In order to solve this problem, remote control technology of underground loader has been developed.

(Line of Sight Control)

Sight distance control (as shown in Figure 2) is the operator's direct observation and control of the equipment outside the dangerous area in the work area. The visual range is generally 5 m to 250 m. The operator can see the vehicle and remote control the vehicle via the radio unit (RRC). Line of sight remote control is widely used.Since the development of sight distance remote control underground loader in 1970s, sight distance remote control underground loader has been developed and applied rapidly.In 1983, Changsha Mining Research Institute successfully developed YK-1, yk-2, ykcy-1.5 and wjd-1.5 remote controlled underground loaders. At the end of 1980s, Anqing copper mine introduced st-5c remote control underground loader from Wagner company of the United States. Especially in recent years, the underground loaders produced by Hengyang Machinery Co., Ltd. of Sinosteel group can basically be equipped with various remote control systems. At present, visual distance remote control technology is adopted on wj-0.4, wj-1.5, WJD-2 and wjd-3 models, and video remote control technology is adopted on wj-1.5, WJD-2 and wj-4 models. A lot of work has been done in this respect. Generally speaking, the automation technology of sight distance remote control underground loader is still improving and developing, new remote control underground loaders are also emerging, and the application scope is also expanding. There is still a big gap between domestic remote control technology and foreign developed countries, so we still need to make efforts to catch up.

First Generation (manual operation)

The first one was produced in the United States in 1958. People operate directly on the LHD at all times. The driver is easy to be tired, easy to make mistakes in operation, and the most unsafe. One person can only operate one console.

Second Generation (remote control operation)

Sight distance: it began to develop in the mid-1970s. LHD is controlled by remote transmitter. The distance is 5-250 m, the most common is 60 m. Drivers often operate the remote control vehicle visually, which is easy to fatigue and make mistakes, and the production efficiency is lower than that of manual control.

Video: The development and development of LHD began in the mid-1990s. The operator can operate LHD with video in the safe area, and can also operate outside the sight distance at the corner.

Third generation (remote control)

Developed in the 1990s, the operator is safe and comfortable. The vehicle runs at the second speed to avoid hitting the tunnel wall. The production efficiency is lower than that of manual control, and it needs to be operated by people, sometimes resulting in operation errors. The remote control distance is 5~2 000 m.

Fourth generation (semi autonomous control)

The LHD was developed ten years ago. The loading of LHD was operated manually and the transportation and unloading were automated.

Fourth generation (autonomous operation)

With the development of 5g technology application, the operator controls LHD in the ground control center, one person can monitor several LHDs at the same time, and the remote control distance is unlimited, which is still under test.

(Remote Control with Video)

When the vehicle runs farther or turns a corner, the sight distance remote control is powerless, so the video remote control is needed. The video remote control is similar to the line of sight remote control system (as shown in Figure 3), except that a video monitor (as shown in Figure 4) is added, which is suitable for the range of 500 m.

(Tele-remote Operation)

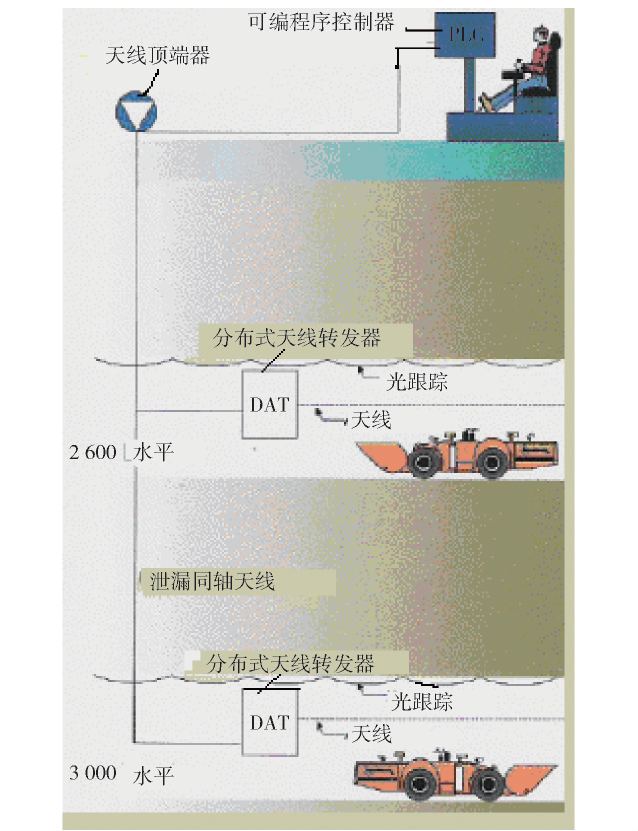

Remote control operation means that the driver remotely controls the underground loader at a ground or underground central control station (as shown in Fig. 5 and Fig. 6), and the distance is within 2 000 m. Tele-remote operation is another step forward to the automatic vehicle.

Fig.1 Manual Control of Underground Loader

Fig.2 Sight Distance Control and Radio Remote Control

Fig.3 Video Remote Control

Fig.4 Video Remote Controller

Fig.5 Schematic Diagram of Ground Remote Control Underground Loader

Fig.6 Ground Remote Control Underground Loader

Semi-autonomous and Autonomous

With the rapid development of computer technology, communication technology and artificial intelligence technology, the latest technology of semi autonomous and autonomous underground loader developed in recent years is the development direction of underground loader technology in the next few years. The biggest difference between remote control and remote control is that a driver can control several machines at the same time, while remote control is that a driver can only control one machine. Semi autonomous and autonomous control are semi-automatic or fully automatic in the whole operation process, while remote control is manual control in the whole operation process. Semi autonomous and self-control vehicles have faster running speed, higher production efficiency and better safety than remote control. The difference between semi autonomous control and autonomous control is that in the whole operation cycle, most of the operation time is automatic, and a small part of the operation time is completed by people. In the production cycle, the shovel loading operation is carried out under the remote control of the operator, and the transportation, unloading and return are completed under the automatic control of the airborne computer. Autonomous control is automatic in the whole operation cycle of loading, transportation, unloading and return. The operator only plays the role of monitoring, which is the most advanced and complex technology in the current mining equipment.

At present, the automation of underground loader has developed to the fourth generation. The next development trend of underground loader is digitization and intelligence. In general, digital and intelligent mines (unmanned mining) are all kinds of dynamic and static information on the ground and underground of mines and engaged in mining mineral resources by human beings. Moreover, it is managed by computer network. Meanwhile, remote remote control and automatic mining can be realized by using space technology, automatic positioning and navigation technology. Mine digitization is the foundation of mine intelligence. Mine intelligence mainly refers to intelligent mining, that is, the mining decision-making process is highly reliable and accurate. The integration of intelligent mining equipment (robot) and modern mining scheduling system is unmanned mining. In China, it will be 25-30 years later, and the whole mine will be remote controlled and automatic mining in a shorter time. What can meet these requirements is the vehicle navigation system.

Navigation is a science to determine the position, direction and route of a vehicle, and then guide the vehicle to move in a logical way to enable the equipment to perform its specific tasks. The underground loader navigation is mainly used to guide the automatic underground loader to transport ore from the stope or ore heap along the specified route to the unloading point, and then automatically return to the original starting point along the original road after unloading. It can be seen that the navigation technology plays a key role in the underground loader automation. It can be said that the development of underground loader automation is developed with the development of navigation technology.

The development of underground loader has gone through manual control, remote control and remote control to the fourth generation of semi autonomous control and autonomous control. Although the automation of autonomous or semi autonomous control has many advantages, it is also a very complex technology. There are only a few mines to realize automation in the whole mining process, and they are concentrated in several large mines. The automation of autonomous or semi autonomous control of underground loaders requires a lot of investment, high technical requirements, and a certain amount of high-quality professionals, this is difficult for ordinary mines, so it is more difficult to popularize it. However, with the development of economy and the progress of science and technology, people's demand for underground loader automation is becoming more and more urgent, and mining automation will become the future development trend.