Understanding the settling of particles is vital to understanding most issues in the coal selection field. The essence of gravity separation is to utilize the differences in settling particles to achieve mineral separation. For example, jigging utilizes the differences in the settling of particles in alternating water flows, shallow slot beneficiation uses the differences in settling of particles in suspension, heavy medium cyclones utilize the differences in deciding of particles in a centrifugal force field, teetered bed separators (TBS) utilize the differences in settling of particles in upward water flows, thickener clarification uses the settling of fine particles in a gravity field, flotation columns use the settling of bubbles in a slurry, and even the transportation of slurry in pipelines involves the settling of particles.

Therefore, understanding particle settling can solve most problems in ore or coal selection. Below is a detailed explanation:

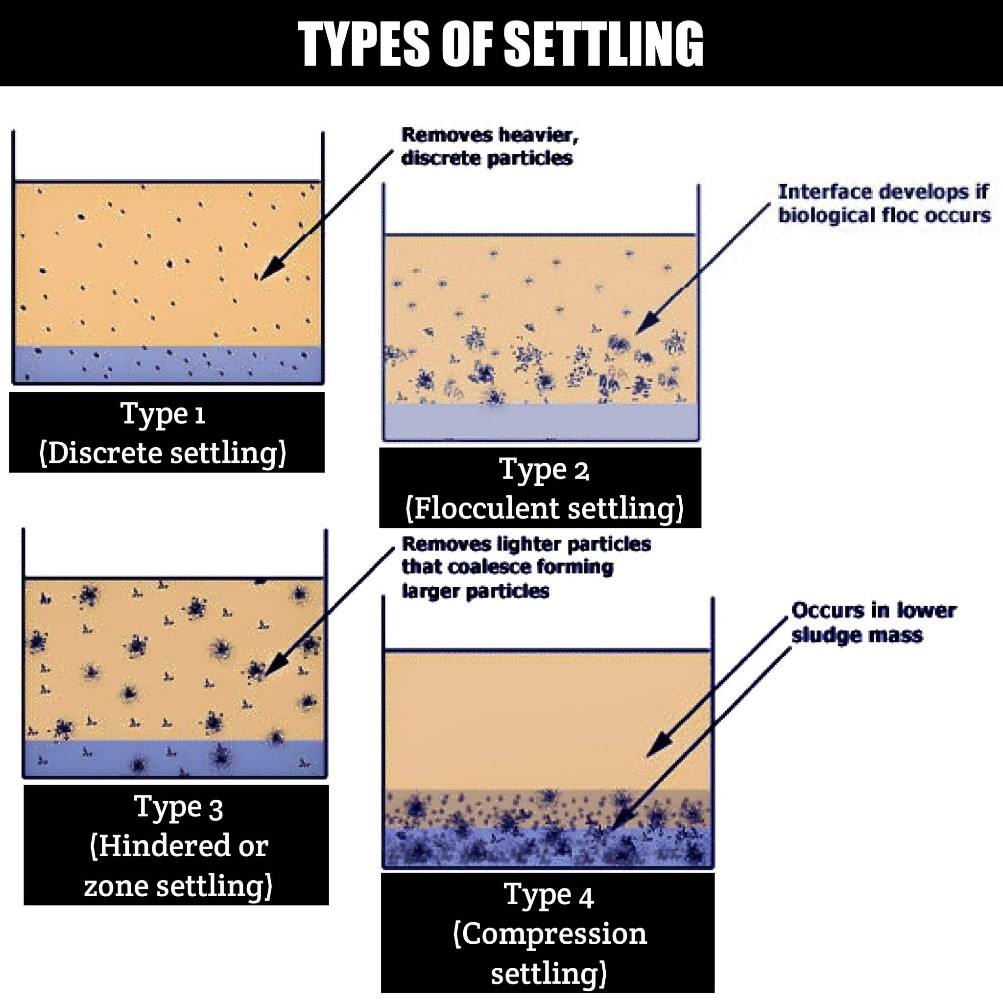

Types of Particle Settling

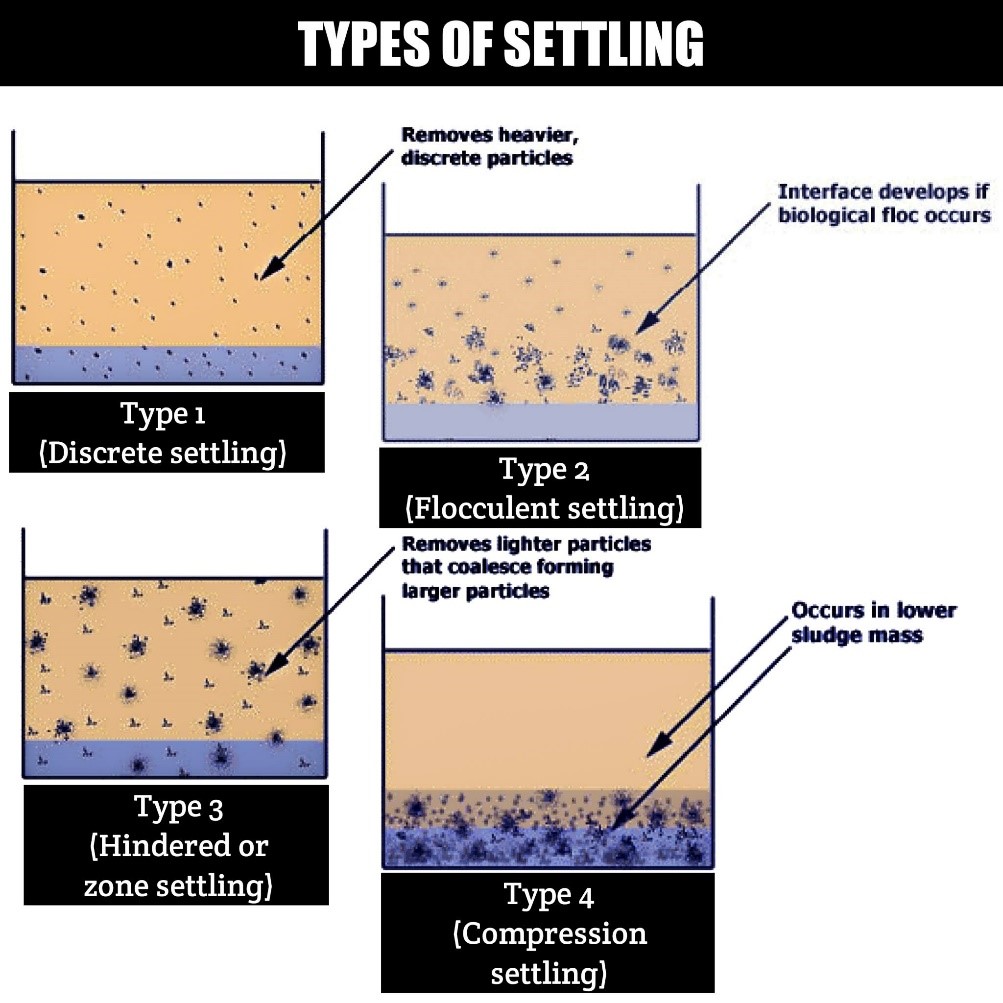

1. Estimation of TBS Upward Water Flow

TBS uses the differences in particle settling velocities in an upward medium flow to achieve separation. The disturbance settling velocity of coarse coal slurry particles is approximately 0.003~0.008 m/s, which is used for estimating the top water volume of TBS. The lower value is used for finer particle sizes, and the higher value is used for coarser particle sizes. For example, a 3-meter TBS requires an approximate upward water flow rate of 120 m³/h, and a 5-meter TBS requires an approximate upward water flow rate of 350 m³/h. More details can be found in the article "Core Technology of TBS."

Summary: After simplifying the abovementioned coefficients, the TBS upward water flow calculation method is 14D*D cubic meters per hour.

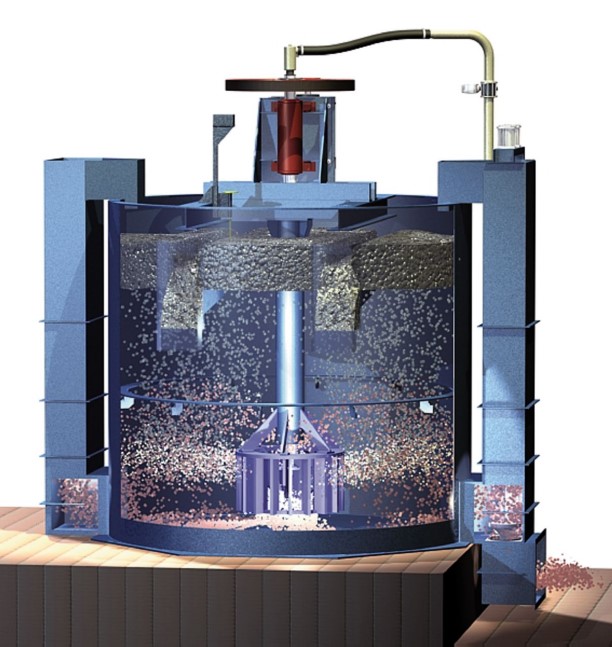

How Teetered Bed Separators (TBS) Works

HOT Teetered Bed Separators (TBS)

2. Estimation of Flotation Column Capacity

When the mineral slurry is fed into the column, hydrophilic minerals rise with bubbles, while hydrophobic gangue begins to sink. The settling velocity of gangue particles determines the speed of the separation process. Therefore, by roughly estimating the settling rate of these particles, we can calculate the processing capacity of the flotation column. For instance, according to the "Design Specification for Coal Washing Engineering," the slurry throughput range for flotation columns is 20-30 [m3(m2*h)], which translates to 0.005-0.008 m/s. This means that the settling velocity of gangue minerals in the flotation column is 0.005-0.008 m/s.

HOT High Separation Efficient Flotation Column

The order of magnitude of this settling velocity is similar to the disturbance settling velocity of coarse particles in a TBS. The main reason for this similarity is that while particles in a TBS are coarse, their volume concentration is very high, resulting in relatively low disturbance settling velocities. In contrast, particles in a flotation column are smaller, but their volume concentration is lower. It can be determined through calculations that the settling rates of particles in both cases are of the same order of magnitude.

Knowing this velocity allows us to estimate the processing capacity of any flotation column. For example, the processing capacity of a two-meter flotation column is approximately 56 m3/h, while a four-meter flotation column can handle around 226 m3/h. For further details, refer to the article "Calculation of Relevant Parameters for Flotation Design."

In summary, after simplifying the coefficients mentioned earlier, the calculation method for the processing capacity of a flotation column is the same as that for TBS: 14D*D cubic meters per hour.

Operation Principle of HOT Flotation Column

3. Solution for Flotation Column Tailings Pipe Blockage

When applied in the ore beneficiation field, flotation columns occasionally encounter the issue of tailings pipe blockage. The main reason for this is the higher settling velocity of coarser particles, preventing them from moving upward from the base of the flotation column to the tailings box. This is primarily due to the prolonged flow rate within the tailings pipe.

To address this problem, the solution is to reduce the diameter of the tailings pipe. By decreasing the diameter of the tailings pipe, the liquid level within the flotation column rises relative to the fluid level in the tailings box. Under these conditions, a more significant pressure head is required while maintaining the same flow rate. Consequently, the flow velocity of the mineral slurry within the tailings pipe is increased, preventing the blockage of the flotation column's tailings pipe by the coarser particles unable to move upwards.

HOT Flotation Column for Mineral Processing

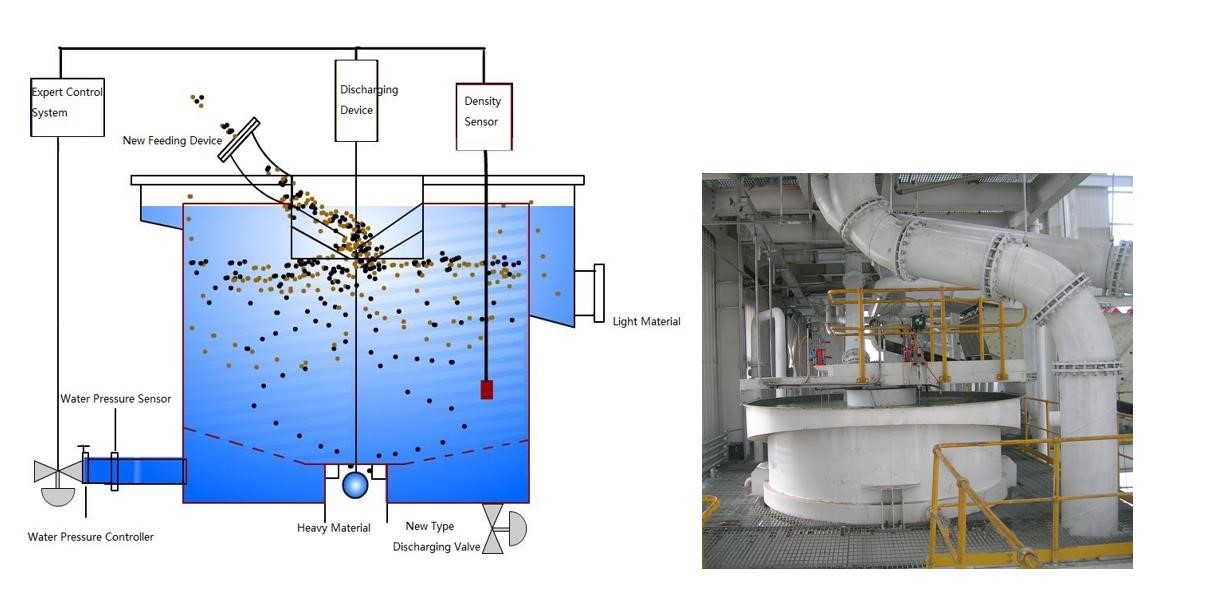

4. Estimation of Thickener Capacity

Similarly, concentrators also utilize the settling of particles to achieve solid-liquid separation. In the "Design Specification for Coal Washing Engineering," the typical surface hydraulic load rate for ordinary concentrators (flotation tailings) is 0.8-1.2 [m3(m2*h)], which translates to approximately 0.0002-0.0003 m/s when converted to units of velocity. The surface hydraulic load rate for raw coal slurry is 2-3 [m3(m2*h)], corresponding to approximately 0.0005-0.0008 m/s in velocity. It can be observed that the settling rate of fine particles is slower. To obtain clear circulating water, the upward flow velocity in the concentrator must be lower than that in flotation columns or TBS.

Furthermore, even with the addition of inclined plates within the concentrator, the surface load rate of flotation tailings only ranges from 1.6-2.4 [m3(m2*h)], equivalent to velocities of 0.0004-0.0006 m/s. This remains within the same order of magnitude, even though the settling area is increased several-fold. Thus, the processing capacity still needs to reach this limit.

By understanding this magnitude, we can estimate the slurry processing capacity of any concentrator with a specific diameter. For example, the processing capacity of a 30-meter concentrator is approximately 1271 m3/h, while a 50-meter concentrator can handle around 3500 m3/h. Further discussions on this topic can be found in the article "Application of Tailings Settling Tests to Guide Concentrator Design and Operation." Of course, this method can also be used to estimate the flow rate of the circulating water pump, as concentrator overflows are essentially circulating water, with only minor differences.

Summary: After simplifying the coefficients mentioned earlier, the calculation method for concentrator processing capacity is 1.4D*D cubic meters per hour.

HOT Large Capacity Thickener

5. Application of Mixer Design

In the article "Key Aspects of Mixer Design," the author derives the necessary inner cylinder diameter of a mixing barrel for different diameters of cyclones and maximum feed particle sizes based on the throughput of the cyclone and the settling velocity of the largest particles. This fundamentally illustrates the design errors in practical engineering related to mixing barrel design, particularly when the mixing pump fails to draw coal. This phenomenon is also attributed to applying particle settling velocity in a suspension. Understanding particle settling resolves the core issue of mixing barrel design, as highlighted in the article.

HOT Double Shaft Mixer for the Mining Industry

6. Analysis of Jigging Principle

The principle of jigging separation still needs to be fully explained today, especially concerning the amplitude and frequency of pulsating water flow, for which a calculation method still needs to be provided. However, it can still be explained using particle settling. For instance, a smaller amplitude of pulsating water flow is required in fine particle jigging separation. This is because when particles rise or fall, they reach their settling terminal velocity within a short distance. The need for multiple frequencies arises from the minimal differences in settling velocities of fine particles. The separation of light and heavy particles is achieved by accumulating the differences in settling distances through multiple cycles.

HOT Mineral Jig Separator Machine

Conversely, coarse particle jigging separation is quite the opposite. The significant differences in settling velocities of coarse particles require a considerable distance to reach their settling terminal velocity. Thus, separating light and heavy particles involves using a larger amplitude of pulsating water flow and a lower frequency. The parameters such as air volume, cycle, and water flow can all be calculated based on the particle settling velocity. These aspects will be further explored in upcoming articles.

7. Discussion on the Circulation Rate and Lower Limit of Separation in Shallow Troughs

Similarly, one must also understand particle settling to comprehend particle separation in shallow troughs. This analysis is detailed in the article "How to Determine the Medium Circulation and Feed Particle Size Range in Shallow Troughs." The central concept is as follows: as the feed particle size in a shallow trough increases, a more significant circulation rate is required to flush it out. Increasing the circulation rate accelerates the horizontal flow velocity within the shallow trough. This, in turn, reduces the vertical settling time for fine particles. Consequently, fine particle gangue cannot settle before entering the overflow, necessitating an elevation of the lower limit for separation in the shallow trough.

HOT Shallow Trough for Mineral Separation

The specific quantitative calculations are outlined in the article "How to Determine the Medium Circulation and Feed Particle Size Range in Shallow Troughs."

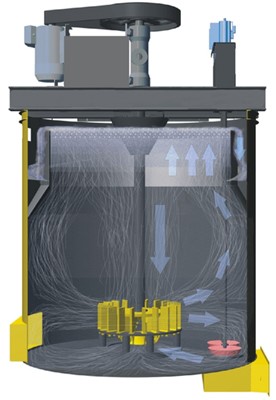

8. Design of Mixing Tanks

In a mixing barrel, particles of different sizes and densities have varying settling velocities. Particles that settle faster require a greater mixing intensity, which in turn influences the selection of an appropriate mixing barrel diameter and the power of the mixing motor. For instance, in the context of ore beneficiation and slurry conditioning, relevant parameters must be calculated to ensure adequate mixing and particle suspension.

Interior Design of HOT Mixing Tank

9. Understanding Classification and Gravity Separation

In a hydraulic classification hydrocyclone, the classification granularity changes as the feed pressure increases. Higher feed pressure increases the centrifugal force on the particles, causing them to settle faster. Fine particles are more likely to be thrown into the outer spiral, resulting in a finer classification granularity. Similarly, increasing the feed pressure in a dense medium cyclone is advantageous for separating fine particle fractions for the same reasons. Furthermore, in the context of pipeline transportation of slurry, the transport velocity influences particle settling behavior. When the transport velocity is too low, particles settle onto the pipeline walls, increasing abrasive wear. As the flow velocity increases, particles will be entrained in the slurry, reducing wear on the pipeline. A more detailed analysis can be found in "Hydraulic Calculations for Pressurized Pipes and Free Flow Pipes."

HOT Spiral Chute for Gravity Separation

Conclusion

The calculation methods for the upward water flow in TBS and the slurry throughput in flotation columns are the same, namely 14.13D*D. The processing capacity of a thickener is calculated as 1/10 of the former, which is 1.413D*D. This simple formula, derived from particle settling analysis, successfully addresses three typical challenges. Understanding particle settling allows us to comprehend the majority of issues within the field of mineral processing, particularly gaining insight into the essence of gravity separation.