Mineral separation plant operators might be aware of this: Finding the right solution for your particular need is not always easy. Many mine preparation plants required a new and effective machine to sort gangue and coal, separating ore from waste before they can be crushed and separated once more.

My old equipment for coal separation, consisting of machines I bought 15 years ago, did not seem to be suitable for my facility's needs anymore, with the progress of science and technology, the air separation equipment is no longer suitable for the needs of most preparation plants. It has low separation accuracy, lacks flexibility, and it is generally combined with crushing and screening.But how could I find a tailored solution among all the new machines and the modern, high-end technology? At this point, I contacted HOT Mining Test Center, inquiring on a new sorting solution to meet my needs – and was invited to have my materials tested at the HOT Mining Test Center. But let me tell the whole story about XRT Intelligent Sensor-based ore sortor!

Initially, I addressed HOT Mining with my requirements and told them all about the materials we work with, which gave HOT Mining's sales team an idea on what I might expect from a new sorting solution. Having received all the necessary information and after some conversations, HOT Mining's team arranged for an upcoming test of my own materials in their Test Center to convince me of their machine’s performance and find the best suitable sorting solution tailored to my needs and materials. From an early stage onwards, I felt really included in the planning process. Based on my requirements and the material I sort in my facility it became soon clear that the XRT Intelligent Separator would most likely be my machine of choice, so that I will have my material tested with an XRT Intelligent Separator machine.

I was astonished by the efficiency of the whole planning process: Before the actual testing date, their team gave me a rough idea on what to expect at the Test Center – no doubt I was working with true separation experts!

A couple of days before the test date, my excitement rose. I was asked to send my ore to the Test Center a few days ahead, leaving HOT Mining some room to prepare and experiment. On the actual test date, HOT Mining's friendly team welcomed me and gave me a tour to the Test Center – there was so much to see! I remember how amazed I was by all the innovative technology I was able to witness on that day.

Finally, we reached the XRT Intelligent Separator, where everything had already been set up for our test. Just moments after the supporting Application Engineer started the sorting process, I was already convinced: this would be my ideal purchase. The precision with which the XRT Intelligent Separator recognized and separated ore from gangue was miraculous. And the speed of it! In fact, this was exactly what I had been searching for. While we watched the process, I was introduced to all the specific functions and performance features of the machine, which combines quite a lot of technologies at once to detect gangue by X-ray, in when running at high belt speeds.The sorting task I wanted to carry out was to precisely separate coal from gangue. As the application engineers knew about my request, they were prepared to solve the problem together with me and would also go beyond and through further possible scenarios.

Unlike other manufacturers I had contacted, I felt like I was treated individually and competently by HOT Mining's team all the way through the testing process.

Close collaboration for an ideal outcome

Throughout my day at the HOT Mining Test Center, I could feel that everything was well-conceived. I deeply sensed that the focus lay entirely on me as a customer, and on their product as the ideal solution to my inquiry. Furthermore, their suggestions for adjustments did not solely focus on HOT‘s own machines. They helped me to plan a holistic process for my plant, including the pre-concentration and pre-processing of the separation.

![]()

After my day at the Test Center, I received a test report listing some results from the test day. The report also provided me with facts and figures, the performance key indicators of the XRT Intelligent Separator in connection with my materials: It neatly contained all the valuable information I needed on the throughput, the overall sorting results and the levels of quality received after the sorting process. The Application Engineers who supervised the testing process had also listed technical specificities concerning my customized XRT Intelligent Separator. With these hard facts in hand, I was convinced I had found the ideal product.

Creating a tailored solution for the customer

Based on the results, HOT Mining submitted me an offer, including the definition of the individually configured product I was going to receive. The day at the HOT Mining Test Center had already left me with the persuasion that HOT Mining would be a reliable and proficient business partner.

Beginning a new era with HOT Mining

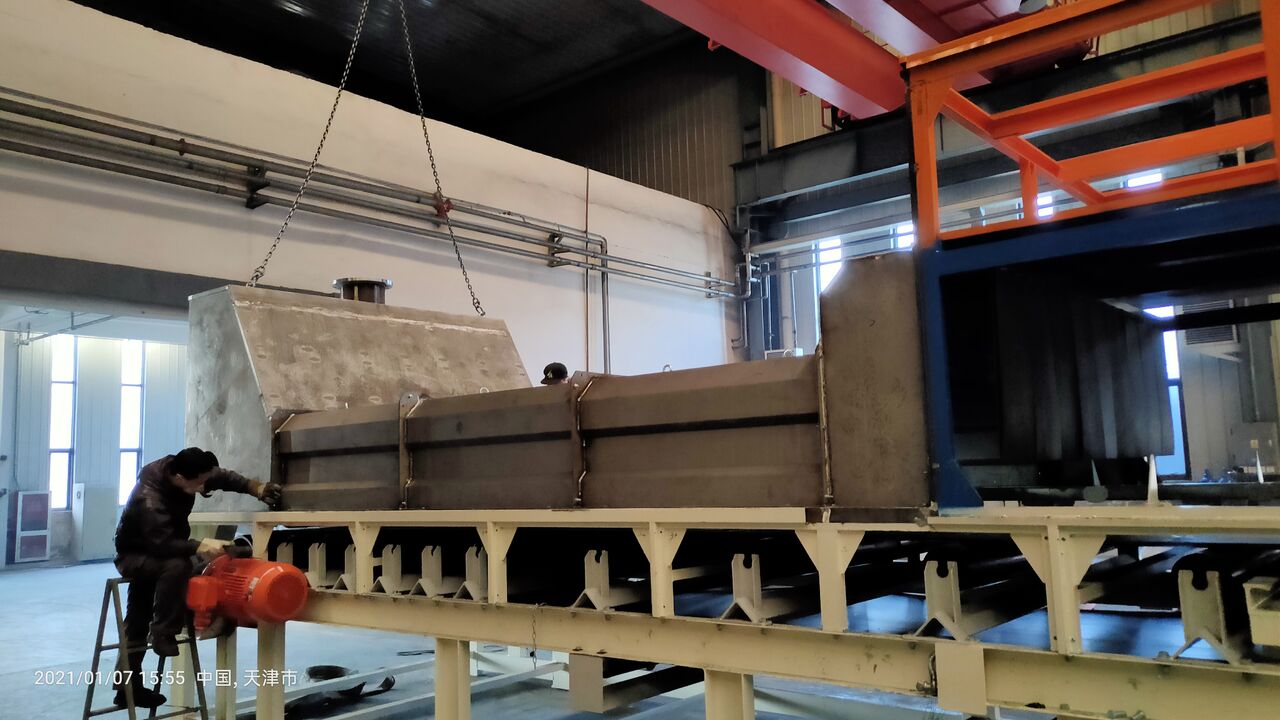

Soon after and after having aligned on all specifics, I placed the order for 1 new XRT Intelligent Separator machine, which will perfectly complement my coal preparation plant and help me increase efficiency and save cost. When the machine arrived on the agreed date, it was already set up based on the results obtained during the tests. Since this pre-setup saved us a lot of time in the start-up phase, one of the HOT Mining service technicians was able to familiarize me and my staff with the technical features and safety regulations of our new XRT Intelligent Separator much earlier.

Even once the machine is up and working, my cooperation with HOT Mining will not cease. Depending on the contract, HOT Mining offers specific maintenance services and checkups to help me keep my machines running at its best.

For me, the arrival and installation of my new XRT Intelligent Separator means a remarkable change in the efficiency and precision of my facility, introducing this advanced and powerful recycling tool to my plant – and I can barely wait.

Contact us

Email: sales@hot-mining.com

Tel:+86 28 8331 1885