Latest Application Case

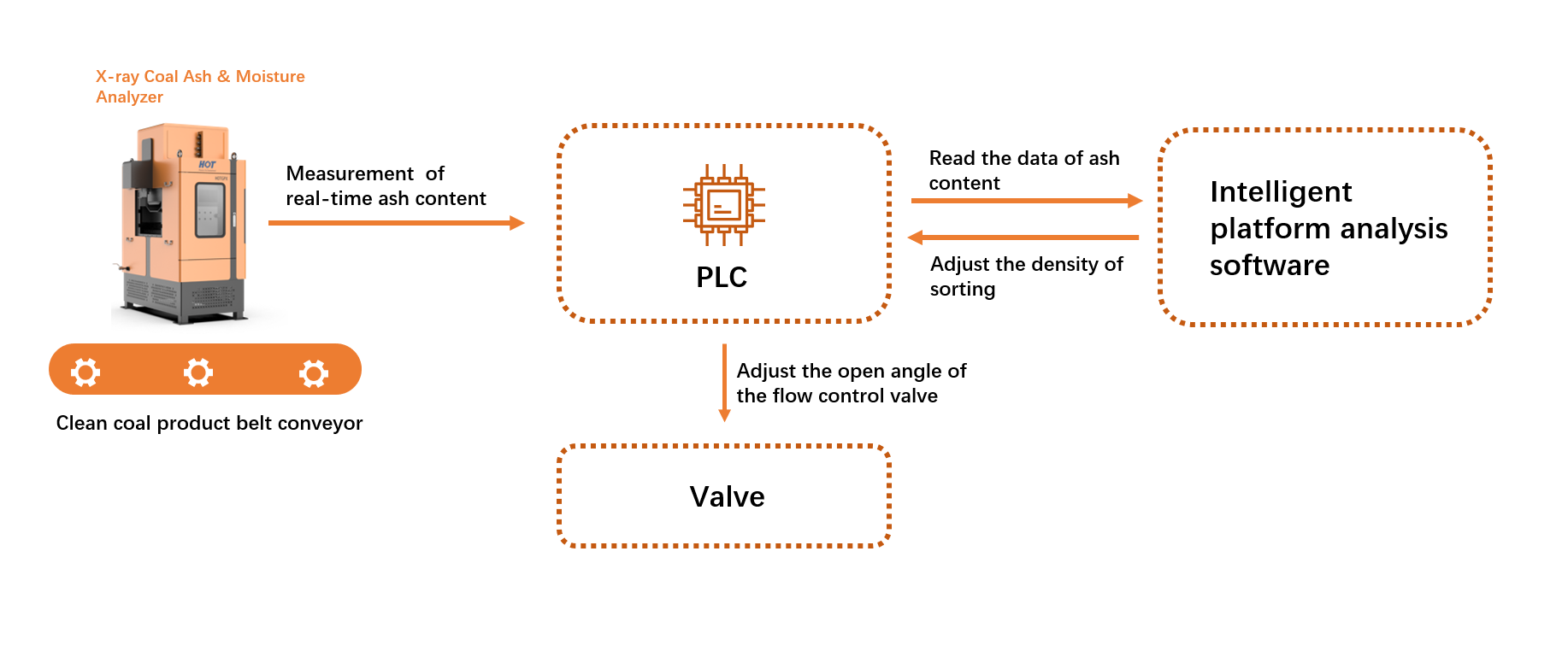

HOT applied the own coined X-Ray Ash Moisture Analyzer on the JiangZhuang fine coal conveyor belt, realizing intelligent control of product index, ensuring the recovery degree of fine coal resources, stabilizing product quality, increasing the recovery rate of fine coal by 0.5%, reducing three positions and labor force, and generating margin CNY 10 million annually.

Why Develop X-Ray Ash Moisture Analyzer?

Ash content is an important indicator to measure the quality of coal products. In addition, to real-time control, the quality of coal products, rapid detection methods, and equipment have been widely used in coal, coking, steel, power generation, and other related industries. For example, steel mills must strictly control the ash content of coking fine coal. According to the data, for every 1% increase in acceptable coal ash content, the ash content of coke will increase by 1.328%; for every 1% increase of coke ash content, the blast furnace ratio will increase by 2.057%, the furnace utilization rate will decrease by 3%, and at the same time, the quality of pig iron will also be reduced. There are four rapid detection methods for coal ash content: radiation measurement, image processing mapping, photoelectric mapping, and weighing method.

Among them, the radiation measurement method is the most widely used by coal enterprises. Radiation measurement can be divided into two categories: active radiation measurement and passive radiation measurement. Dynamic radiation measurement mainly uses the principles of low-energy gamma-ray backscatter, high-energy gamma-ray absorption radiation, and dual-energy gamma-ray transmission. Therefore, gamma radiation source needs to be used inevitably, but due to their penetrating solid ability and rugged shielding, there are significant security risks. In addition, the test conditions of low-energy gamma-ray backscatter are complex and are generally challenging to meet on-site; the high-energy gamma-ray transmission is greatly affected by the high atomic number of elements and heavy fractions residue in coal. Passive radiation measurement measures the gamma rays released from the radioactive elements (potassium, cesium, thorium, uranium, etc.) during the decay process in coal and uses the correlation between them and the ash content to measure the ash content of coal. The primary defect of passive radiation measurement is that the natural radioactive elements deposited in coal are very few, so this method often cannot detect the sedimentary sandstone in coal, thus limiting its generality. Only when the natural gamma-ray emission content of potassium, thorium, and uranium released by coal and the mineral content of coal have a reasonable correlation is the passive radiation measurement suitable for use.

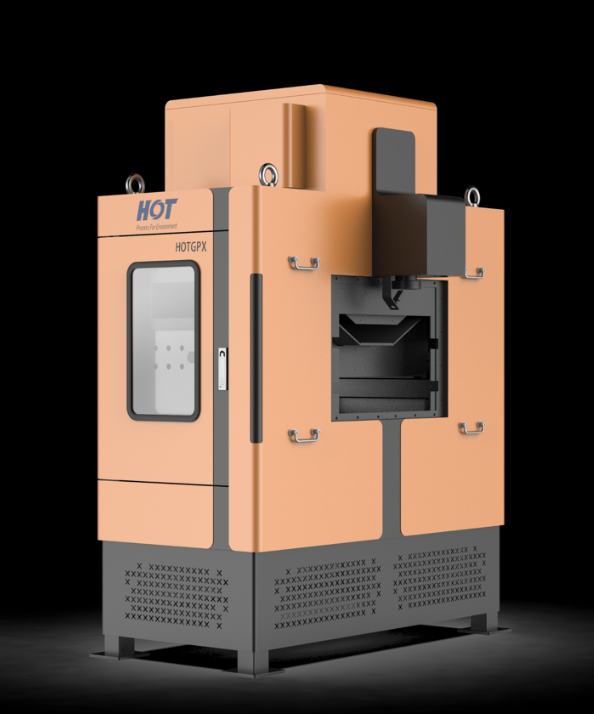

Given the radiation hazards, great management difficulties, low measuring accuracy of active radiation measurement, and the limitations of passive radiation measurement, HOT (Chengdu) Industries Co., Ltd. has independently coined the X-Ray Ash Moisture Analyzer. This ash meter adopts a class Ⅲ X-Ray device, which has less harm to human health and the environment, its radiation can be controlled, and its measuring accuracy is better than that of conventional radiation measuring instruments. The X-Ray Ash Moisture Analyzer integrates intelligent detection, recording, display, control, and other technologies used to measure and control the change in coal ash content. It is an excellent blessing for industries with high accuracy requirements.

The X-Ray Ash Moisture Analyzer (Picture 1) mainly comprises a thickness compensation system, ash detection system, radiation protection system, temperature control cooling system, automatic alarm system, and X-Ray Ash Moisture Analyzer platform software. The ash detection system consists of the X-Ray source and linear array detector, and the temperature cooling system uses industrial air conditioning heating and cooling system.

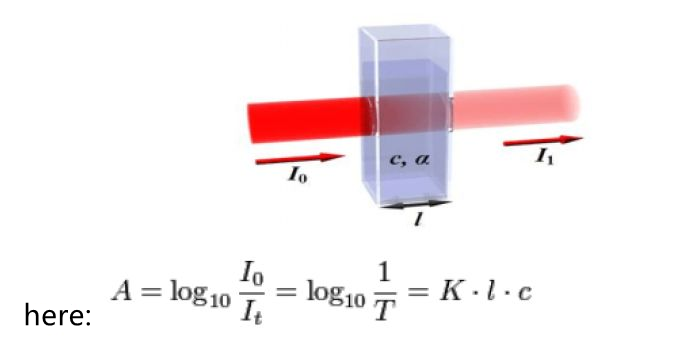

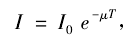

The detection principle of an X-Ray Ash Moisture Analyzer is based on Beer-Lambert Law:

And this formula can be transferred as below.

In which I0 and I are, respectively, the incident and transmitted ray intensity; μ is the mass absorption coefficient; T is the thickness of the tested object.

Since the narrow X-Ray beam transmits substances according to the exponential decay law, the X-Ray Ash Moisture Analyzer has a thickness compensation system and real-time detection of coal sample thickness during the test. The thickness value is entered into the ash calculation algorithm model.

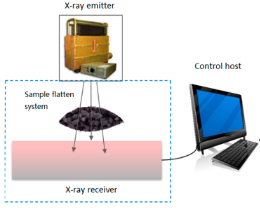

As shown in Figure 1, when the coal sample enters the X-Ray Ash Moisture Analyzer testing area, the X-Ray dual-energy source emits high-energy X-Rays and low-energy X-Rays. The receiver at the bottom of the tape receives the attenuation value after the high-energy X-Rays, and low-energy X-Rays transmit the coal sample and then send it to the control host. According to the preset model, the control host calculates the coal sample ash.

Unlike the traditional gamma ray ash meter double-source single-point sampling detection, the X-Ray Ash Moisture Analyzer adopts fan-shaped detection, so the detection area is vast. In addition, the X-Ray Ash Moisture Analyzer can also adjust and optimize itself according to the field coal characteristics through a self-learning algorithm, thus significantly improving the detection accuracy.

X-Ray Ash Moisture Analyzer Testing Effect

The particle size of heavy medium coal in the coal preparation plant of JiangZhuang Coal Mine is below 50mm, and the width of the belt conveyor is 1200mm. According to the production practice, the HOTGPX® X-Ray Ash-Moisture Analyzer was selected. From January 2 to February 22, 2023, the ash meter detected 108 groups of data. The ash meter detected ash, artificial assay ash curve, and two ash absolute errors are shown in the following Figure. It can be seen from the Figure that the minimum ash of the fine coal is 9.40% (artificial assay value), and the maximum is 11.39% (artificial assay value). In production, the ash content of the fine coal products should be controlled between 10.50%-11.00%, so when the ash content of the fine coal is lower than the required ash content, the yield of the fine coal will inevitably be reduced. In comparison, when the ash content of the fine coal is higher than the required ash content, the quality of the fine coal will be unqualified. Due to the severe lagging of the artificial assay results, it is impossible to guide the production (adjustment and control of separation density, referred to as "density control") in an exhibition.

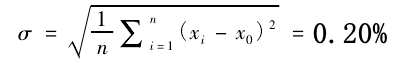

This Figure shows that the ash detected by the ash meter and the artificial assay ash are almost consistent, and the maximum and minimum absolute errors of the two are 0.47% and -0.48%, respectively. Therefore, the probability of fundamental error between the artificial assay ash and the ash detected by the ash meter being less than 0.25% is 78.45%, and the standard deviation (σ) is:

According to this, the probability that the absolute error between the artificial assay ash and the ash detected by the ash meter is less than σ is 67.77%, and it is less than 2σ is 95.65%.