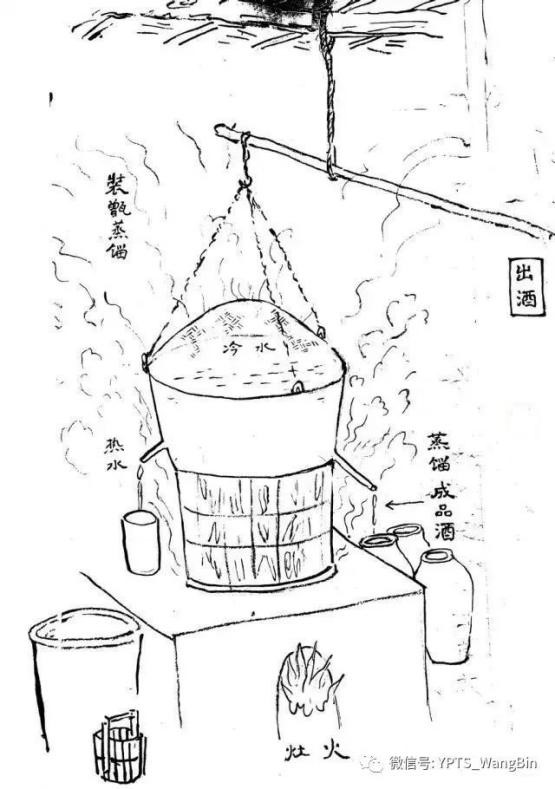

In ancient China, there were simple filter presses, marking the earliest appearance of filter presses in history. During the Han Dynasty, relatively simple filtration and filtering equipment was used in brewing, where wine was consumed with the dregs. This was a way of drinking, as recorded in the "Han Shi Wai Zhuan" by the Han Dynasty scholar Han Ying: "The tyrant revels in wine, turning ponds to navigate, the fermented dregs form hills that can be seen for miles" This record reflects that the society at that time had awakened to a particular scale of wine production and had learned how to separate wine from the wine trough.

In 1965, the Ministry of Light Industry organized a yellow wine filter press trial, and the BKY54/820 air-mode plate and frame filter press appeared. This marked the end of China's traditional manual pressing and filtering method.

In the early 19th century, Germans had a great fondness for drinking, which drove the development of the German wine industry. Local enterprises invented the world's first plate-and-frame filter press to enable rapid wine production, thus causing the industry to grow.

Development of Filter Press:

The first-generation filter press is suitable for dewatering high-ash, fine-grained, high-viscosity coal slurry and fine coal. The product moisture and concentration are good, but it has many disadvantages, such as low processing capacity, long processing time, large volume, and complex operation.

Second-generation Filter Press: It is an improvement for the problems of the first generation.

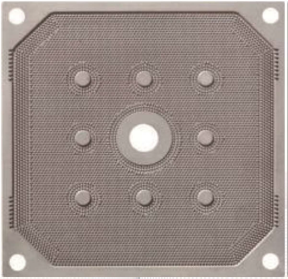

(1) Filter Plate Material: The number and size of filter plates must be increased to increase processing capacity and filter area. In addition to cast iron filter plates, new chemical material filter plates have appeared.

1250-Type Diaphragm Filter Plate

(2) Filter Plate Structure: New steel-reinforced filter plates are used, with a thin rubber film pressed on the surface and around the rubber. This type of filter plate is lightweight, easy to repair, and has good anti-yield properties.

(3) Safety Facilities: An optoelectronic safety shield is installed on the side of the filter plate to monitor and ensure safety. When the operator's body interrupts the light beam of the optoelectronic tube, the filter plate stops moving. When the person leaves the light beam, the equipment starts automatically.

(4)Automation: Some manufacturers have developed fully automated filter presses for continuous production.

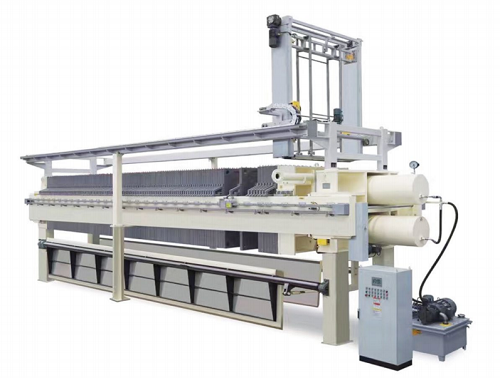

Third-generation Filter Press: The VPA filter press developed by the American company Denver Sala is representative of the third-generation filter press. Compared with traditional second-generation filter presses, it has more robust and durable filter plates, larger model size, increased filtration pressure, and reduced cycle time.

Fourth-generation Filter Press: The APN filter press produced by the Spanish company TH is representative of the current new generation of filter presses. Compared with the third-generation filter press, its notable differences are smaller machine size, more straightforward structure, less space occupation, fewer filter plates, faster cycles, and mechanical extrusion process.

High-Pressure Diaphragm Automatic Cleaning Filter Press-HOT Industries

Regarding the development and current advanced technology of filter presses, we welcome everyone to add comments!

Contact us:

WhatsApp: +86 15756877473

Email: sales@hot-mining.com