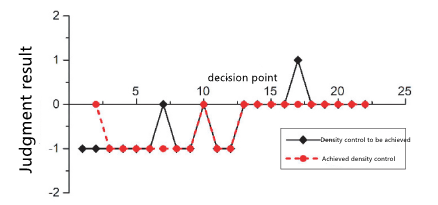

To effectively reduce manual sampling, guide the operator to adjust the density, and solve the problem of the extensive and lagging manual test, an intelligent density control system based on an X-Ray ash analyzer was developed and connected to the production system to adjust the production parameters directly. They randomly sample the ash data within 48h of the above-detected ash data, according to the preset density control algorithm for density control adjustment judgment. As shown in the figure below, the judging result of 0 indicates that the fine coal ash is within the target range; Judging result 1 demonstrates that the fine coal ash is slightly higher and needs to be adjusted down by one density step; Judging result 2 indicates that the fine coal ash is more elevated and needs to be adjusted down by two density steps; Judging result -1 demonstrates that the fine coal ash is slightly lower and needs to be adjusted up by one density step; Judging result -2 indicates that the fine coal ash is more down and needs to be adjusted up by two density steps.

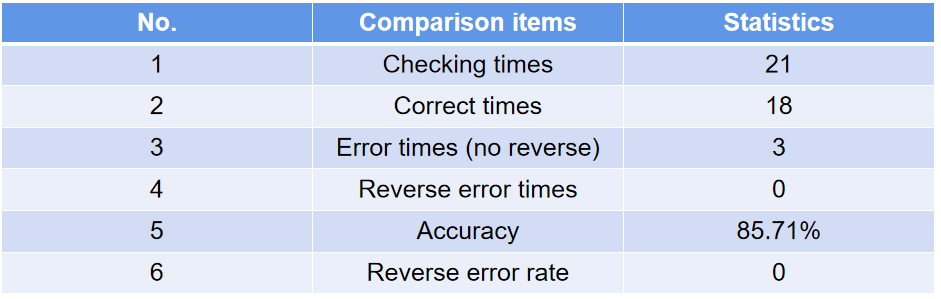

The Table below shows a comparison table of ash content detected by an ash analyzer and human manual density adjustment. The below Table shows that in the 21 times of human density adjustment decisions, the intelligent density control system based on an X-Ray ash analyzer has 18 findings consistent with human decisions, with an accuracy rate of 85.71% and no reverse decisions.

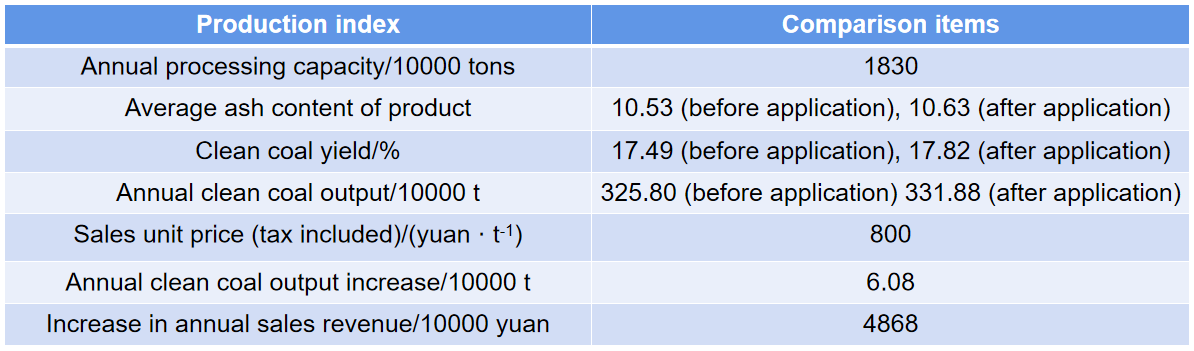

The Table below calculates the economic benefits after applying the intelligent density control system based on X-Ray ash-moisture analyzer in this plant. As shown in Table 4, due to the large scale of this plant, only one product ash content control (average ash from 10.53% to 10.63% and stably maintained) can achieve an increase of CNY 48.68 million in annual sales revenue. In addition, the intelligent density control system based on an X-Ray ash analyzer can also effectively reduce manual sampling work and human input in production.

X-Ray ash-moisture analyzer can not only avoid the radiation hazards of active ash analyzers but also make it safer to use and adopt the fan-shaped detection mode; the detection area is vast, and it can more accurately reflect the real-time fluctuation of ash content, and the detection accuracy is higher, which breaks through the limitation of the application of passive ash analyzer. Furthermore, through self-learning, the X-Ray ash analyzer can adjust and optimize itself according to the characteristics of the field coal, significantly improving the detection accuracy and applicability of the use. In addition, the intelligent density control system based on an X-Ray ash-moisture analyzer can also effectively reduce the amount of manual sampling work and timely guide the density adjustment in coal selection production, solving the problem of the extensive and lagging manual test.

Currently, the series of ash analyzer products can meet the ash detection requirements of all coal products. HOT's X-Ray ash analyzers have been widely used in coal selection plants in China, with the intelligent density control system creating considerable economic benefits for coal preparation plants.

Contact us

Email: sales@hot-mining.com

Linkedin: Click here