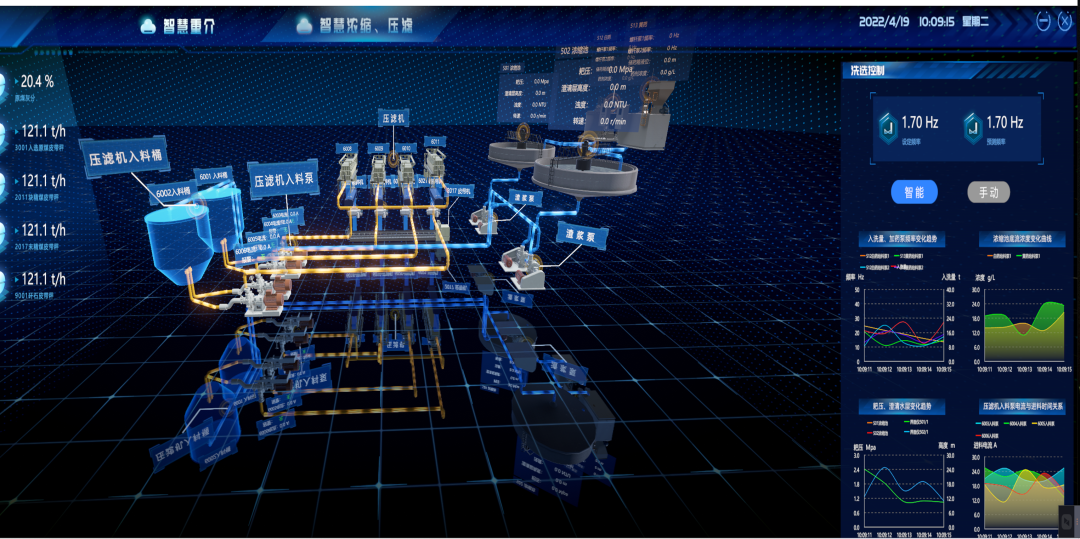

HOT has implemented an intelligent filtration system at the Tucheng coal washing plant, which mainly includes modules such as filter press monitoring, automatic feeding, automatic end of the feeding, automatic queue unloading, filtration production statistics, system auxiliary equipment monitoring, etc.

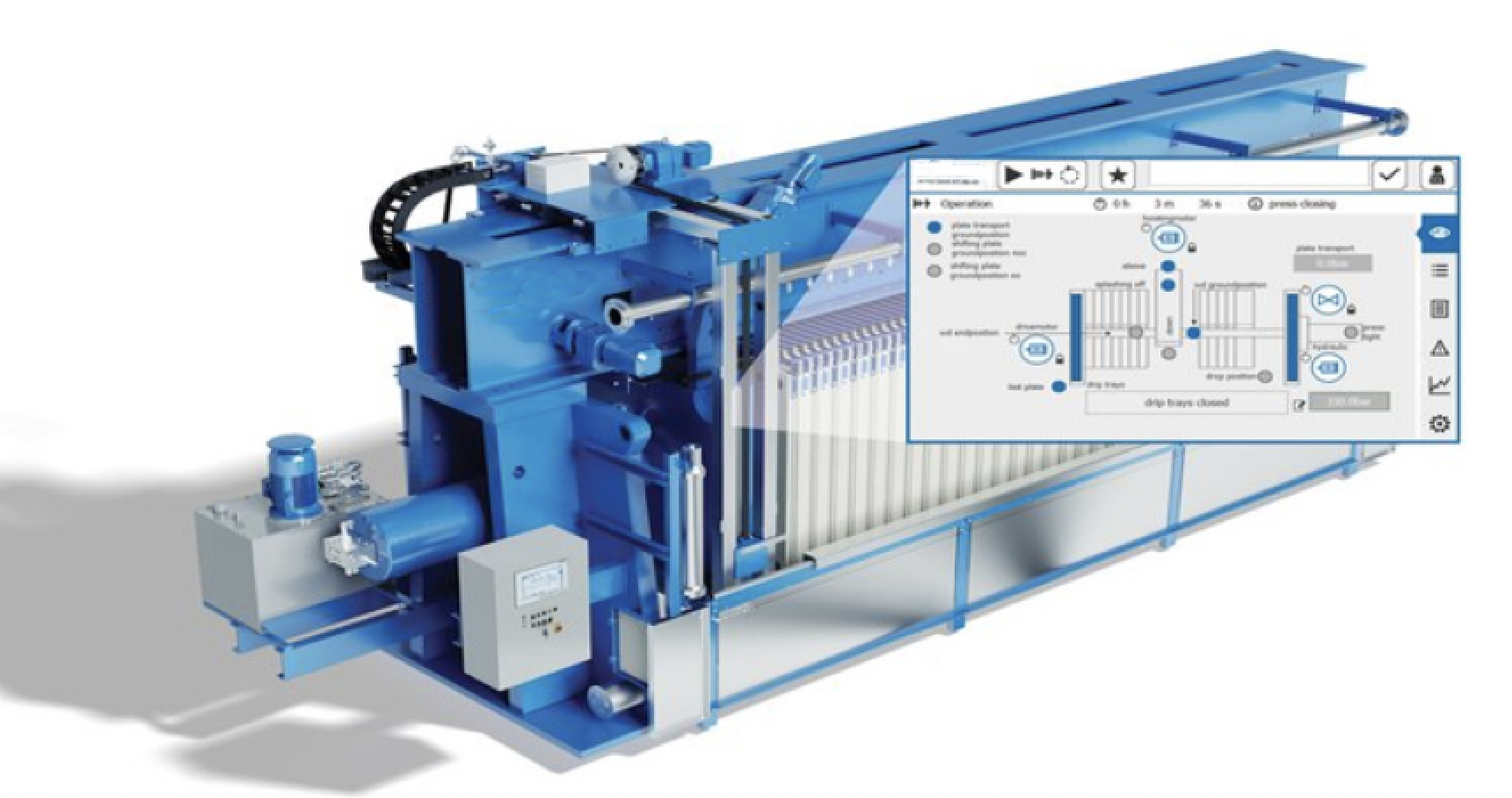

The intelligent filtration system is based on parameters such as time, flow, and pressure, and a pressure transmitter and flow meter are installed on the site filter press. When the feeding requirements or liquid level alarm are reached, the filtration control system will link multiple filter presses. The filter presses will be queued for feeding, realizing automatic and intelligent feeding. The unloading status monitoring device will monitor the filter plate opening and closing according to the filter cake attachment on the filter plate. The system will automatically assist in cleaning the unloading through the vibrator installed on the filter press to achieve automatic and intelligent unloading. It is understood that the system will connect the PLC signal of the filter press to the server background, and the collection control system will be connected with the filtration system, taking the collected filtration system data as the control node. Through the automatic filtration control system, the linkage control between the filter press and the scraper machine, and the filter press and the filter press can be realized, ensuring that the entire cycle control of the filter press is unmanned.

After the intelligent upgrade of the filtration system, it replaced the traditional personnel on-site control of the filter press operation, overcoming the problems of significant personnel demand, high work intensity, strong experience dependence, and low system efficiency of the coal preparation plant filtration system. The system can automatically feed, automatically judge the end of the feeding, automatically queue for unloading, and perform other functions, improving the filtration system's overall working efficiency.

"There are four filter presses in the coal preparation plant. After the comprehensive intelligence of the filtration system, the same raw coal in washing quantity was used as the basis for statistics. After the intelligentization, the mud produced by each shift increased by 12 boards. As a result, the personnel on duty decreased from 3 to 1, and the production efficiency was greatly improved", Camus Zhang, the R&D Director, introduced.