(Continuing from the previous section...)

Disadvantages of XRT Technology:

1. High Equipment Costs: XRT technology requires high-precision instrumentation, resulting in higher equipment costs.

2. High Ore Requirements: XRT technology has high requirements for ore morphology and density and may need to perform better with some challenging-to-sort ores.

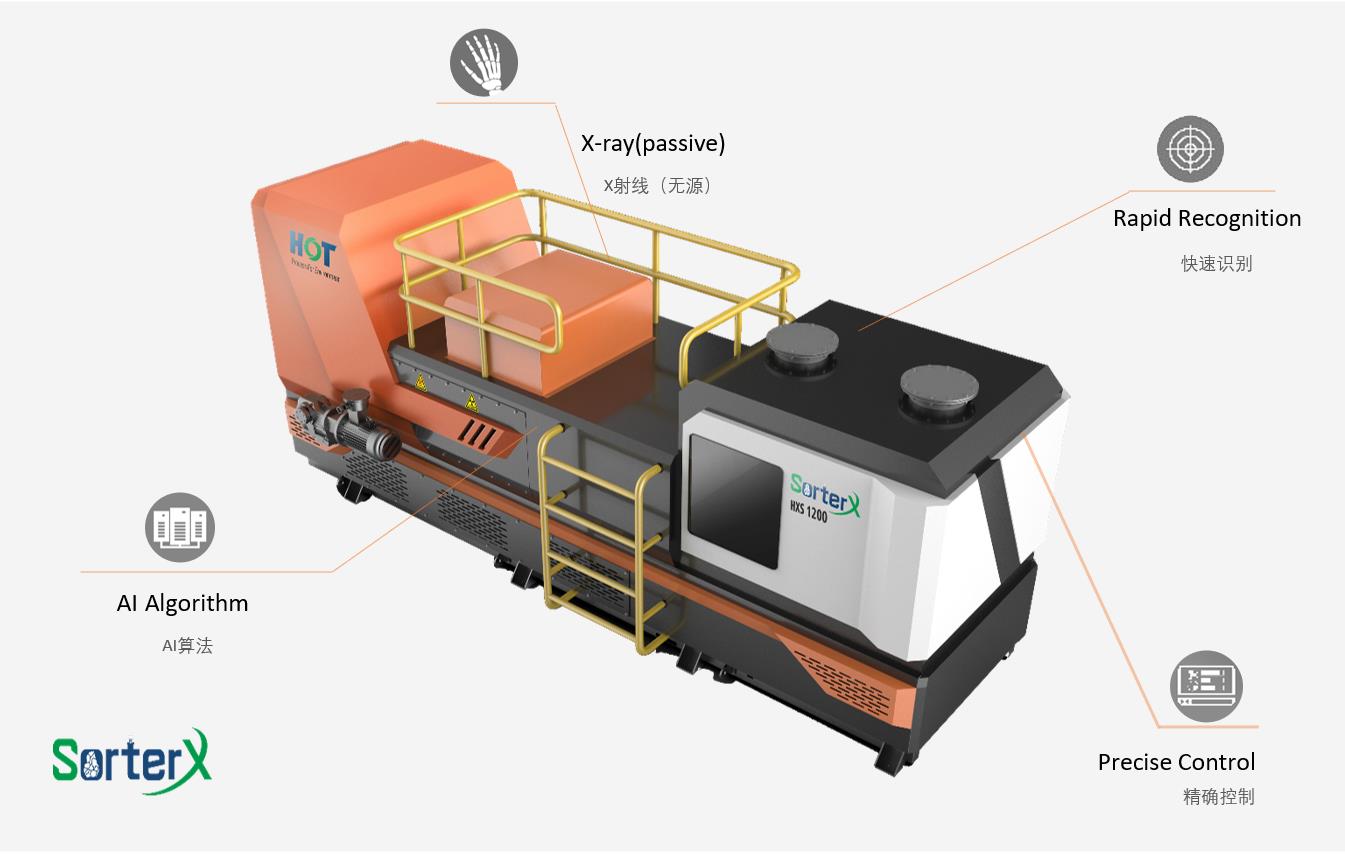

Over time, XRT Pre-Concentration (Sorting) equipment has progressed beyond the research and development stage. Today, XRT Pre-Concentration (Sorting) equipment typically uses an array of high-frequency air valves to control compressed air blowing onto different areas of the target material, achieving the separation of target minerals from waste rock. This type of equipment is usually compact in structure with a small cross-sectional area, making it adaptable to various site conditions. Therefore, it can also be installed underground during mining operations to pre-select ores, leaving waste rock underground for backfilling and reducing ore transportation volumes.

XRT Water-free Pre-Concentration (Sorting) Machine Schematic Diagram

XRT Water-free Pre-Concentration (Sorting) Machine Model

3.2 CCD Color Sorting Process

CCD color sorting technology is a widely applied sorting technique, especially in mineral sorting. Its principle involves using CCD cameras to capture images of materials, analyzing the fabrics through an image processing system, and ultimately achieving the sorting of materials. This technology offers advantages such as high sorting accuracy, efficiency, and broad applicability. However, it has disadvantages, such as high costs and stringent material requirements.

Standard CCD color sorting equipment includes X-ray, laser, high-frequency vibration sorters, and more. These devices have different applications in various scenarios, and users can choose them based on their specific needs.

In summary, applying CCD color sorting technology has brought convenience and efficiency to mineral sorting. However, it is essential to consider its pros and cons and select the appropriate equipment and solutions for specific applications.

3.3 XRF Open-Pit Mining Area Modeling and Pre-Concentration (Sorting)

This technology typically combines X-ray fluorescence (XRF) detection with particle size distribution estimation to visualize ore information in target mining areas, enabling Pre-Concentration (Sorting) or pre-marking within the mining site.

By installing high-speed XRF sensors on mining equipment and utilizing XRT (X-ray transmission) technology along with software algorithms, this method assesses the ore grade in a specific mining area during excavation operations. It then models this area and marks ore information for different blocks. This guidance allows mining trucks to separate waste rock, surrounding rock, and high-grade ore during ore loading and transport. Waste rock and surrounding rock are directed to waste rock processing, while valuable minerals are selected. The entire detection, analysis, marking, and transport guidance process runs in real-time without human intervention.

This process can also provide information about the distribution of harmful elements, thereby enhancing product quality.

Through this technology, unnecessary mining and sorting operations can be reduced, ore grade at the processing plant can be improved, and the amount of ore entering the mill can be reduced, ultimately increasing the efficiency of the processing plant.

XRF Open-Pit Mining Area Modeling and Pre-Concentration (Sorting)

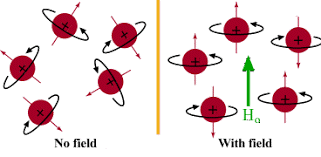

3.4 Belt-Based NMR Batch Pre-Concentration (Sorting) Technology

This technology utilizes real-time transmission analysis techniques to analyze large ore blocks, such as NMR (Nuclear Magnetic Resonance), to analyze the initial ore blocks extracted from open-pit mining sites. It assesses the ore grade within a specific length of the moving conveyor belt, marking different segments (waste rock, ore) accordingly. Subsequently, it uses ore flow adjustment mechanisms such as active flap valves and rotating buckets to direct materials with different markings to their respective flow paths, thereby achieving significant tailings within the mining site.

This approach is typically applied in open-pit mining operations, allowing for continuous and large-scale Pre-Concentration (Sorting) and dry tailings disposal. It significantly enhances the ore grade from the pit, eliminating the influence of waste rock and surrounding rock contamination on the processing plant's production.

NMR analysis technology is suitable for a wide range of particle sizes without strict limitations on ore particle size. As a result, belt-based batch Pre-Concentration (Sorting) technology is a relatively coarse sorting technique and holds promising prospects for large-scale ore processing applications.

Principle of NMR

4. HOT's Pre-Concentration (Sorting) Technology Solution System

HOT (Chengdu) is committed to innovating and developing mining technology, providing advanced, reliable, cost-effective, intelligent Pre-Concentration (Sorting) products and technical services to the mining industry. HOT offers tailored solutions for different types of ores, mining methods, and scale applications.

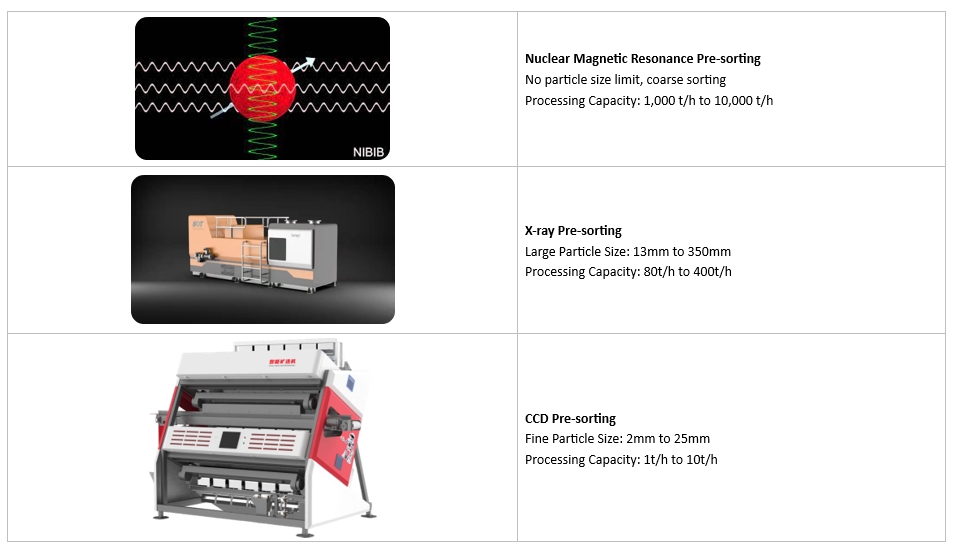

Modular Pre-Concentration (Sorting) system provided by HOT: Large Batch Pre-Concentration (Sorting) + Coarse Particle Water-free sorting + Fine Particle Water-free sorting

HOT's Pre-Concentration (Sorting) technology system covers various stages of ore Pre-Concentration (Sorting), including the waste disposal phase at the mining site, coarse particle Pre-Concentration (Sorting), and fine particle Pre-Concentration (Sorting). In the waste disposal phase at the mining site, HOT employs NMR analysis Pre-Concentration (Sorting) technology, allowing for selective redirection of materials from different conveyor belt sections at a polar-effective cost, achieving the Pre-Concentration (Sorting) of large quantities of ore. During the coarse particle Pre-Concentration (Sorting) stage, HOT's XRT water-free Pre-Concentration (Sorting) technology offers high precision, ensuring continuous and efficient coarse ore sorting. In the fine particle Pre-Concentration (Sorting) stage, HOT's CCD color sorting technology provides precise material separation at a small particle size scale, enabling efficient sorting under small particle sizes.

The various Pre-Concentration (Sorting) techniques within HOT's Pre-Concentration (Sorting) technology system can be deployed in combination or individually, depending on the ore type, mining conditions, and processing plant requirements. This flexibility allows for coverage of different stages of ore Pre-Concentration (Sorting), ultimately contributing to sustained profitability for businesses.

The technical value of HOT's Pre-Concentration (Sorting) system includes:

1) Increased resource utilization and extended mine life:

Pre-Concentration (Sorting) technology improves the ore grade entering the mill, allowing mining operations to continue below the boundary grade.

2) Reduced tailings volume:

Most waste rock is removed in advance, preventing it from entering subsequent milling and flotation processes, resulting in reduced tailings volume.

3) Optimal resource utilization:

Waste rock and surrounding rock removed during Pre-Concentration (Sorting) can be used as construction aggregates or fill materials, maximizing resource utilization.

4) Lower milling costs:

Increasing ore grade and reducing the amount of ore entering the mill reduces energy consumption and costs associated with milling processes.

5) Lower mining costs:

Pre-sorting reduces the ore's demands on mining processes, lowering mining costs.

6) Reduced average ore transportation costs:

Pre-sorting removes waste rock, reducing the tonnage of raw ore transported to the processing plant.

7) Process optimization and reduced capital investment for new beneficiation plants:

Ore Pre-Concentration (Sorting) leads to process optimization, reducing the amount of ore to be processed in subsequent stages such as milling and tailings handling. This significantly lowers the capital investment required for new beneficiation plants.

5. Conclusion

In the current mining industry, mining companies are increasingly focused on achieving precision and maximizing the value of their operations. To achieve this, it is essential to consider ore Pre-Concentration (Sorting) techniques either during the early planning stages of a mining project, including the research and development and construction preparation phases, or during regular production years through technical and economic analysis to select the optimal Pre-Concentration (Sorting) techniques or process upgrades..

Pre-Concentration (Sorting) methods based on ore properties often have more pronounced limitations based on ore type. In contrast, Pre-Concentration (Sorting) methods based on sensors and algorithms offer a broader range of applicability. They can be flexibly configured and integrated into various stages, including mining sites, mines, processing plants, and ore transportation sections. Additionally, these methods offer high levels of automation, efficiency, and controllable sorting metrics. Therefore, enterprises should carefully conduct necessary analyses and trials to select the most suitable Pre-Concentration (Sorting) techniques for their specific needs when considering Pre-Concentration (Sorting) technologies.

(The End)