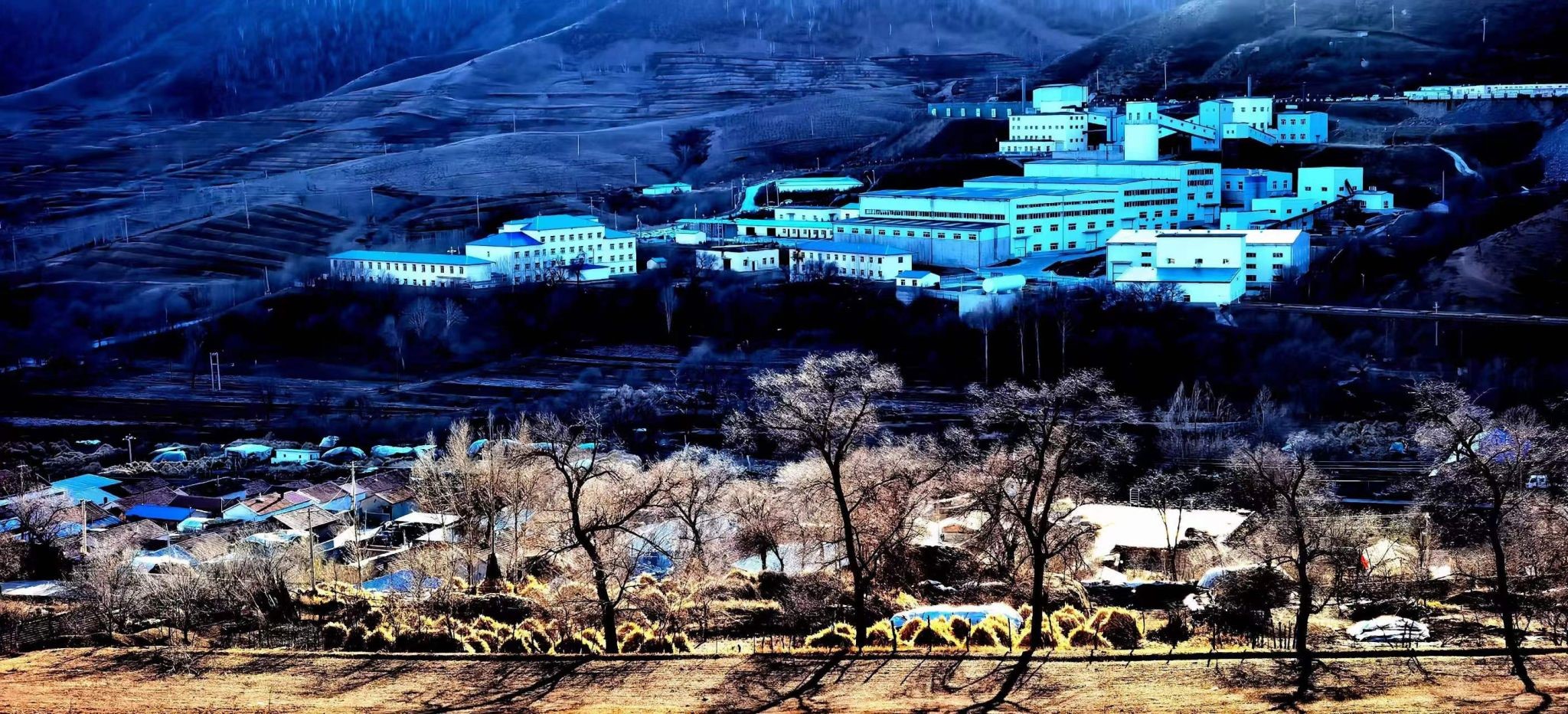

The processing plant is transforming to be different in the future. The primary drive is that improved value outcomes constantly change. Recently, change has been driven by the demand for more efficient water and power use and reducing greenhouse gas emissions. Only in the last two to three years have mining companies come to us saying that they need a greenhouse gas evaluation on their projects. For most projects, we are looking at greenhouse gas emissions.

Rapid progress for the mining industry is a reasonably fast change in approach, and it all needs to be managed carefully. However, the bottom-line objective remains unchanged: improved shareholder value within the environmental, social, and governance frameworks set by the government and society.

Rapid progress for the mining industry is a reasonably fast change in approach, and it all needs to be managed carefully. However, the bottom-line objective remains unchanged: improved shareholder value within the environmental, social, and governance frameworks set by the government and society.

Unwilling to deny that energy and water consumption is more urgent than others.

Low energy efficiency and massive water consumption have become the predominant issue in numerous processing plants worldwide, especially in China, Mongolia, and other water-deficient areas. There are fundamental social reasons for this. Processing projects can have an actual and perceived impact on the water supply for rural regions. As a result, there is a move to increase the use of sensor-based sorting methods like XRT and CCD color or bulk sorting for pre-concentration that can discharge many rejects at the very beginning. With this technology, mineral processing plants can save much energy for grinding, flotation, and tailing systems. Indeed, it also helps to minimize water consumption.

HOT is already seeing changes across the whole mining and processing chain, from screening to tailing. We are endeavoring to develop more environment-friendly technology to improve concentrate yield during processing.

Contact us

Email: sales@hot-mining.com

Linkedin: Click here