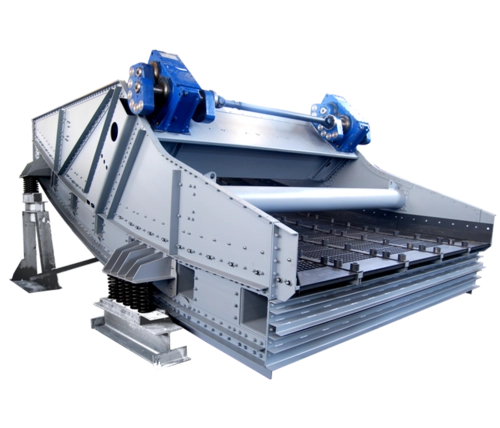

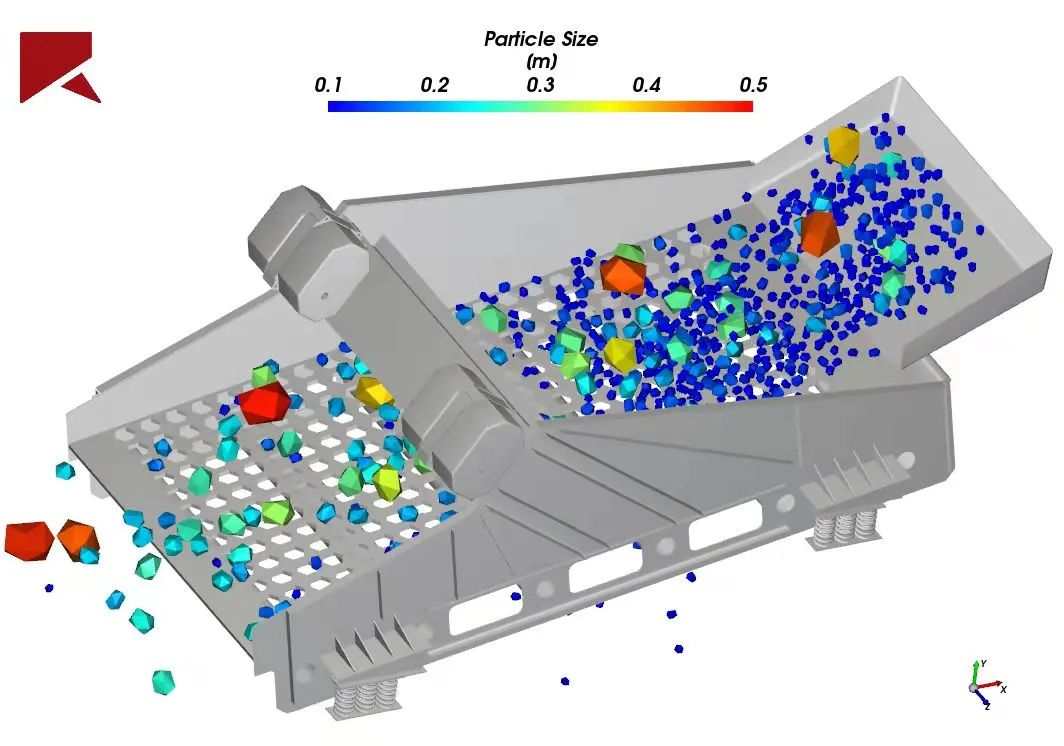

A vibrating screen is a large, heavy piece of equipment widely used in the mining industry. Unfortunately, the difficulty of daily maintenance and upkeep of vibrating screens leads to frequent equipment failures. The fundamental reason for this is that vibrating screens are products that scientifically utilize the destructive power of vibration.

For traditional machinery, unconventional vibrations generated during equipment operation are one of the precursors of equipment failure. However, vibrating screens use vibration to change the material's motion trajectory and achieve screening effects. Although the vibration industry has never stopped designing and researching optimization structures to combat destructive forces, an effective solution has yet to be found. As a result, equipment failures for vibrating equipment still occur frequently.

Vibrating screens are usually arranged in the throat of the production process system. If several minor problems during equipment operation cannot be detected promptly, the vibrating screen may cause significant failures. This can result in the entire production system shutting down, causing substantial customer losses. In mining, coal, metallurgy, and other industries, sudden accidents and shutdowns directly affect production schedules. The loss of profits ranges from tens of thousands to millions of yuan. Most importantly, premature failures of vibrating screens during operation will directly threaten the safety of inspection personnel's lives.

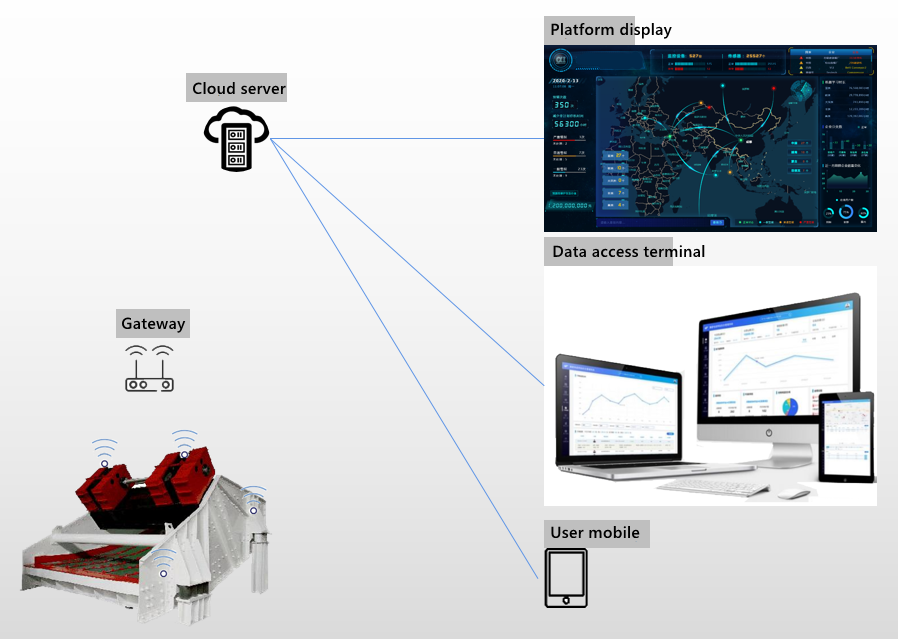

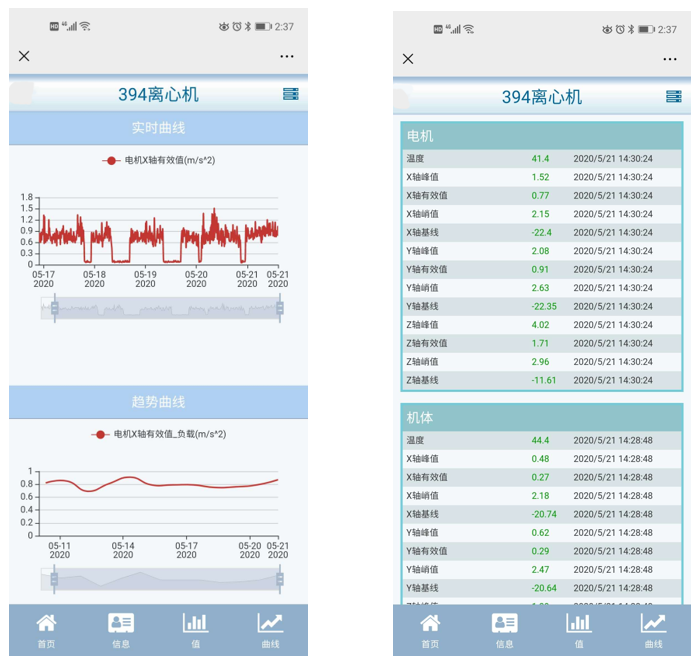

The PHM maintenance system for vibrating screens developed by HOT Industries uses sensor technology, automatic control technology, Internet of Things technology, and big data technology to monitor various operating parameters of vibrating screens in real-time online. In addition, the system uses intelligent extensive data analysis to analyze equipment performance status and provide early warning of faults. In the factory, the system promotes products to the market and offers better services to customers by understanding the usage of the products in the enterprise in real time. For customers, the system can arrange equipment maintenance time reasonably according to equipment operation monitoring, reduce the staffing, material, and financial resources invested in emergency equipment repairs, and improve production efficiency and benefits.

The system functions

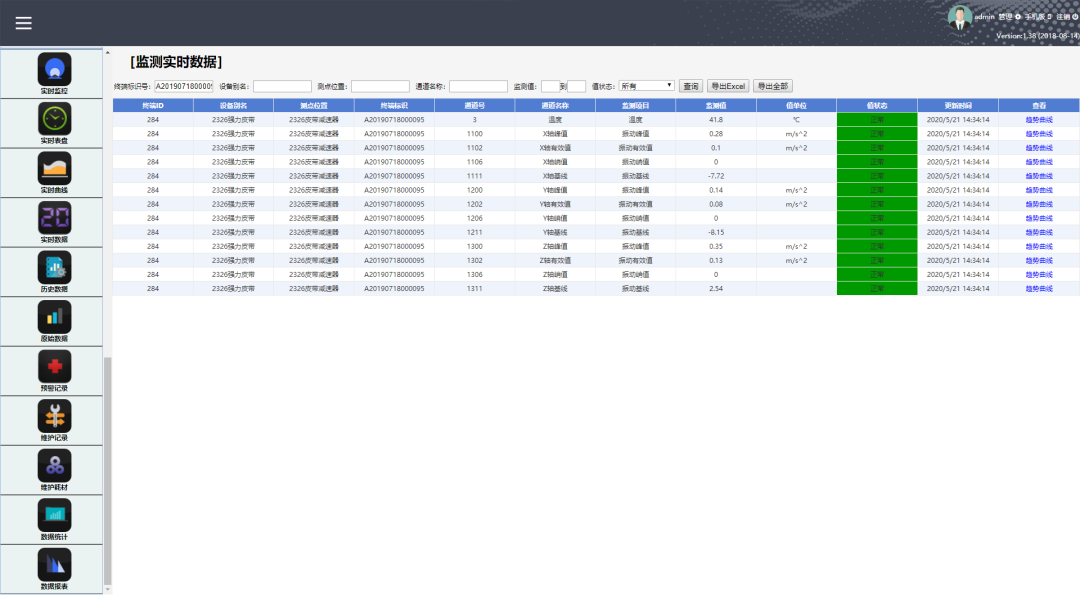

1) Monitoring function: continuous status monitoring and browsing historical data.

2) Alarm function: automatic warning, automatic alarm, WeChat push alarm information.

3) Analysis function: equipment condition prediction, maintenance plan push.

4) Auxiliary function: equipment QR code management.

5) Push function: AI algorithm analysis and report generation push to WeChat client.

6) Monitoring parameters: motor vibration temperature, screen body vibration intensity, screen body vibration angle, screen body vibration balance, exciter operating bearing temperature, lubricant temperature, etc.

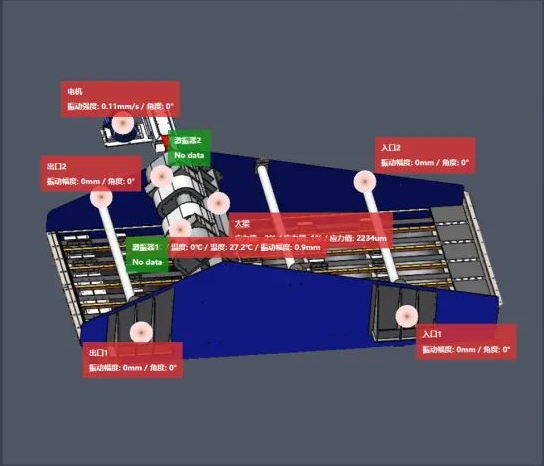

Real-time online monitoring

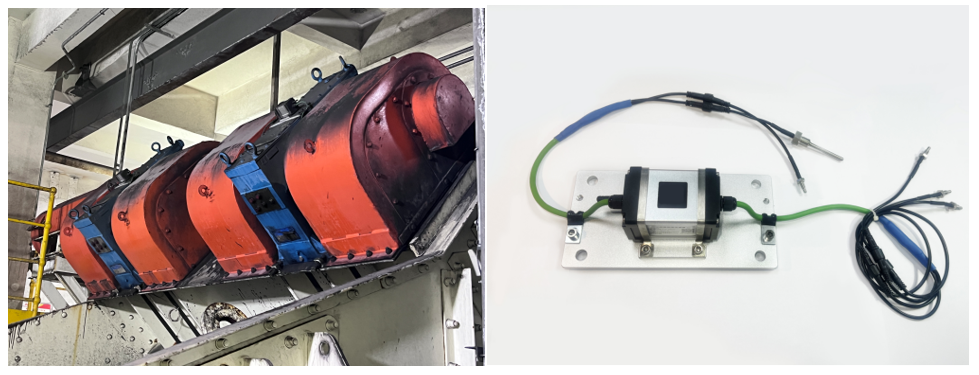

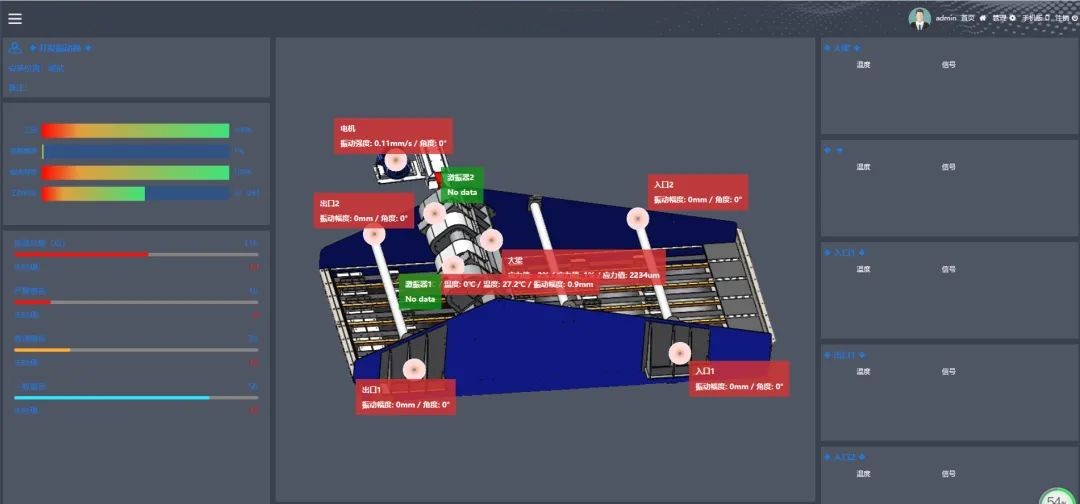

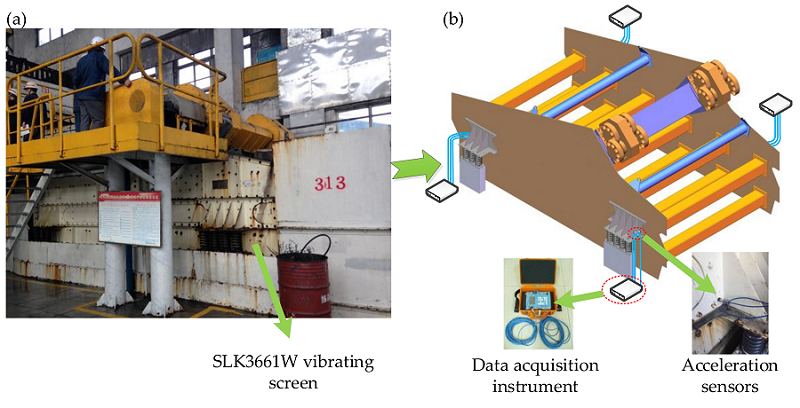

Real-time online monitoring is conducted on the core components of the vibrating screen, primarily focusing on monitoring the motor vibration temperature, vibration balance of the feed inlet before and after the screen, vibrator vibration, four bearing temperatures, and lubricating oil temperature. To ensure accessible data collection and reduce implementation difficulty, on-site sensors are battery-powered and utilize wireless data transmission. The sensors monitor and collect vibration and temperature data for a particular duration at set intervals and wirelessly transmit the data. A relay is deployed near the vibrating screen to receive data from multiple sensors and send the data to the enterprise cloud platform for data analysis via the on-site or 4G/5G network. Real-time online monitoring can effectively monitor the vibration balance of the screen during equipment operation, uneven feeding, and vibrator bearing faults, allowing timely detection of equipment failures and corresponding measures to avoid accidents.

Continuous state monitoring

HOT Industries' PHM system utilizes multi-channel state monitoring technology designed explicitly for the vibrator in the vibrating screen. It is cross-connected with the vibrator in the vibrating screen to detect and evaluate phase defects, examine and record bearing and gear vibration, operating oil temperature, and overall machine motion in six degrees of freedom (three translations and three rotations).

Main features:

1) Machine condition visualization.

2) Detailed view of the selected machine status.

3) Real-time push of dashboard data.

4) Responsive web design - dashboard panels adapt to screen resolution and panel interaction.

5) Time zone and language automatically adapt to the client system. 6) Alert push within the threshold limit range.

Cloud platform & cloud services

The cloud platform employs big data, artificial intelligence technology, and other technologies to establish equipment models and algorithms, continuously training and learning to improve the reliability and accuracy of equipment failure warnings. By introducing the model with long-term monitoring data and using real-time data as input, the trend of various monitoring indicators can be predicted and analyzed to determine equipment performance status and predict equipment failures. Fault information is promptly pushed to the relevant personnel through the APP or WeChat public account for timely measures, eliminating faults in the bud.

The cloud platform stores equipment monitoring data, allowing users to view equipment operating data and historical monitoring data anytime, anywhere through mobile phones, computers, and other devices. It also provides reliable operating monitoring data to optimize product design and continuously improve product quality for equipment enterprises.

Analysis of data and alert users can integrate into a BI dashboard and WeChat/APP notifications. These warnings enable customers to schedule vibrator replacements one week before a fault occurs, preventing unnecessary process downtime and saving significant maintenance costs.

Using cloud-based intelligent digital services, deviations from normal operations can be detected earlier than ever, far beyond traditional threshold warnings. It combines machine learning technology with traditional machine process knowledge, providing specific dashboards, notification indicators, and access to a machine's fault mode database for quick corrective action. In addition, this service collects and evaluates data from the overall operation, such as vibration, speed, pressure, temperature, etc., and monitors essential measurement values to prevent harm to personnel and damage to machines.

HOT Industries cloud service advantages:

1) Capture process data, including vibration, speed, pressure, temperature, etc.

2) Associate all values through artificial intelligence (machine learning).

3) Machine-specific dashboards for maximum transparency.

4) Access to the entire machine's fault mode database for quick corrective action.

5) Broad applicability to match various types of vibration screens.

Intelligent services for vibration screens include a data-driven model that predicts normal behavior based on historical data and current machine and process operations. Its powerful new feature is how it handles the differences between measured and predicted values, reflecting the degree of deviation from normal operations. Machine learning algorithms monitor not only individual values but also the correlation of all values, especially the operating mode of the machine or process at any given time.

HOT Industries' PHM maintenance system is committed to the smooth operation and intelligent operation of vibration screens, from initial real-time monitoring to industry expert support for historical equipment issues. Customers can access real-time dashboards with KPI information on mobile devices and get all relevant information anytime, anywhere.

Global overall settings and systematic layout optimization enable customers to obtain data interpretation, maintenance suggestions, and maintenance methods on the client side, supplemented by considerable historical data support at various levels, assisting the factory's workforce.

Future research directions: HOT Industries is developing a new type of vibration screen PHM system that can monitor the movement, status, and performance of vibration equipment and the rate of unbalanced vibrators driving vibration screens and feeders. With minimal installation work, a wireless sensor can be installed on the cover of the vibrator using a magnet. Once the vibrator is fatigued, the sensor picks up high-frequency signals from worn bearings and gears.

Contact us

Email: sales@hot-mining.com

Linkedin: Click here