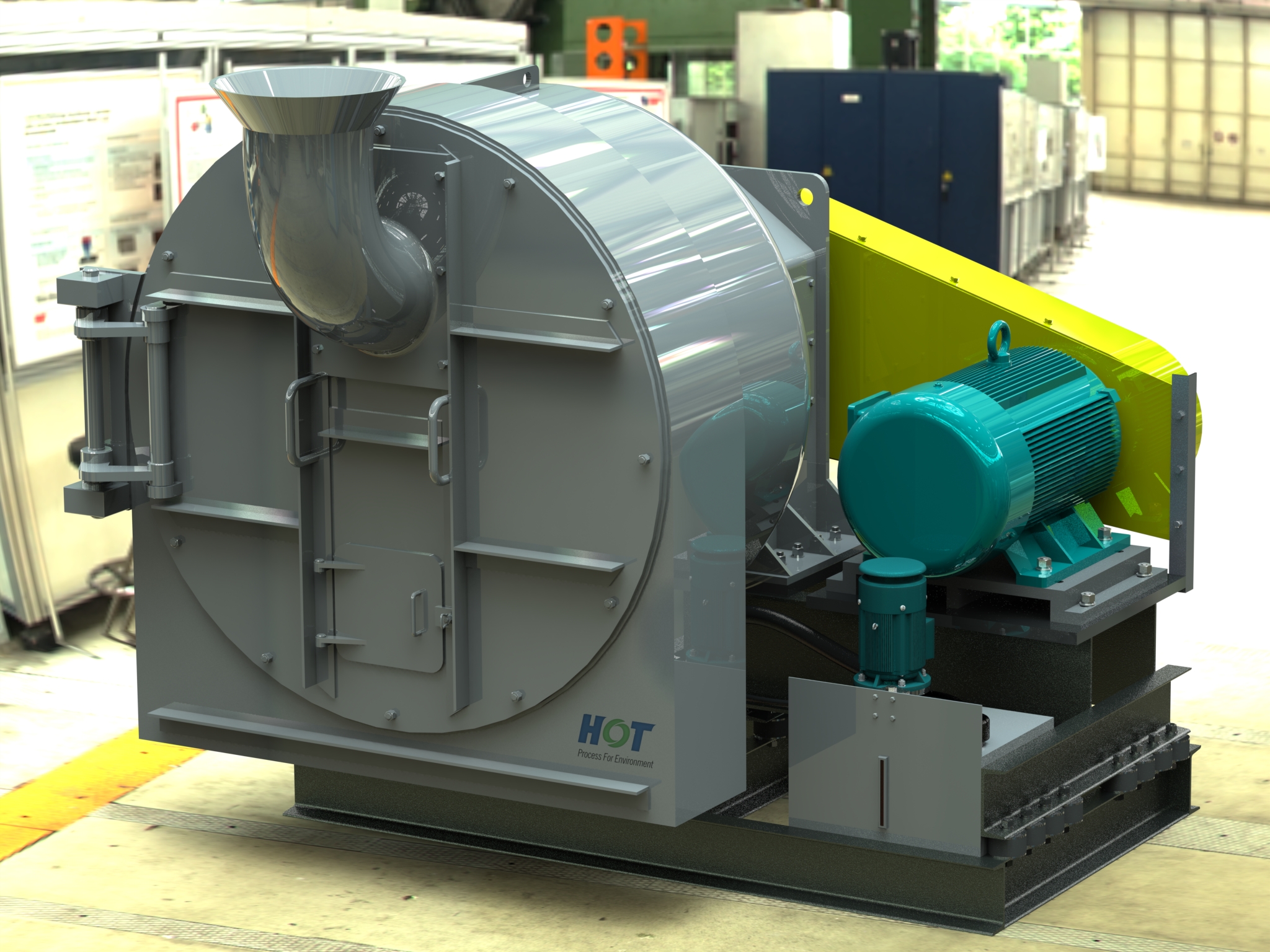

1. Working Principle of HFC1200 Centrifuge

HFC1200 Fine Coal Centrifuge is a horizontal scraper fine coal centrifuge with high centrifugal force and screen basket. The slime to be dewatered enters the screen basket through the feeding barrel on the door, and the liquid in the pulp is separated from the target solid particle layer under the centrifugal force generated by high-speed rotation; the slime cake formed on the screen basket is scraped and continuously moved from the small end of the screen basket to the large end, so as to achieve the functions of screening and dehydration.

2. Equipment Structure

1) Base assembly: The base is fixed to the ground with bolts, and supports the oil pump and oil tank components. The upper base supports the gearbox, the screen basket support drive assembly, the drive motor, and the V-belt protection assembly.

2)Feeding:the feeding barrel is embedded to the door of the centrifuge, which facilitates the removal and replacement of the screen basket.

3)Gearbox: the gearbox consists of differential mechanism, main bearing, seal and bearing components, and the main bearing supports the screen basket;

4)Lubrication system: oil pump, motor, filter, fuel tank, pressure switch, etc. The oil pump sends oil into the bearing and circulating gear system.

5)Drive device: The main drive device consists of a fixed motor pulley and a V-belt. The main drive motor is mounted on the motor frame. The oil pump motor assembly is mounted on the oil tank unit.

3. Evaluation of the dehydration effect of HFC1200 centrifuge

(1) Dehydrated product moisture (mass percentage, %): It is the most direct indicator to judge the effect of dehydration.

(2) The solid concentration of centrifugal liquid (g / L): It refers to the solid content in the centrifugal liquid per unit volume.

(3) Dehydration speed (L / min): It is usually expressed by the volume of the centrifuged liquid obtained within a certain period of time.

The process factors that affect the dewatering effect of the centrifuge are usually the concentration of the material, the particle size composition of the material, the gap between the scraper and screen basket.

It can be seen from the above table that with the increase of the feed concentration, the product moisture significantly decreases, the dehydration speed slows down, and the concentration of the centrifuged liquid decreases, but the change is not obvious.

Influence of different particle size on the dehydration effect

It can be known from Table 3 that the particle size composition has an influence on various indexes for evaluating the dehydration effect. With the increase of the fine particle content in the feed, the indexes have a tendency to worsen. The reason is that as the particle size becomes finer, the fine particles are fully filled in the pores of the material layer formed by the large particles.

Note:Under the situation of 48.6% feeding concentration,15.3% fine coal(<0.25mm) content and 8mm distance between scraper and screen basket.

It can be known from Table 4 that as the sieve gap is enlarged, the moisture content of the product is greatly reduced, and the dehydration speed is accelerated, but the concentration of the centrifuge solution is also rapidly increased. The actual production conditions show that with the increase of the sieve slot, the product moisture no longer drops significantly because, with the discharge of fine particles and water, the centrifugal force is not enough to overcome the water molecules in the later stage of dehydration (discharge end) and the adsorption of coal surface.

5 Conclusion

In summary, the concentration of raw materials, the granular composition of raw materials, the gap between the screen basket and the scraper, and the gap between the screen seams have different degrees of influence on the dewatering effect of the centrifuge. Therefore, in actual production, it must be:

(1)Appropriate concentration of feeding material is best if the concentration of feeding material is about 50%;

(2) It is best to ensure a suitable particle size composition of the material, and the content of <0.25mm grade does not exceed 20%;

(3) To ensure the appropriate scraper and screen basket. The gap between the 6 and 10mm is the best;

(4) to ensure a suitable screen seam;≤ 0.5mm is the best.

In addition, the speed of the feed rate has a great impact on the dehydration effect of the centrifuge. The feed rate is too fast, the product moisture is too high, the dehydration rate becomes lower, and the concentration of the centrifuge solution is reduced; otherwise, the feed rate is too slow, and the product moisture is reduced. , The dehydration speed increases, and the concentration of the centrifuge liquid increases. Therefore, in the production process, the feed rate should be adjusted reasonably according to the actual situation, so that the centrifuge can achieve the best usage effect.