Background:

Coal is a significant energy and chemical engineering resource in the world. The reasonable development and utilization of coal resources have meaningful significance to the economy and environment of the world, especially for countries with extensive production and consumption of coal, such as China. Ash content is a crucial evaluation parameter of coal quality and a standard that guides the reasonable utilization of coal. However, the conventional ash content measurement is to heat the coal in a muffle furnace at a temperature higher than 800 °C, which causes increased consumption of energy and time. Additionally, timely adjustment of operating parameters in the coal preparation plant could not be achieved due to the delay of ash content result that was usually obtained after several hours. Therefore, coal industry researchers need to seek real-time ash content measurement techniques.

Thus, HOT (Chengdu) Industries Co., Ltd has developed real-time ash content measurement, which is the fundamental condition for the timely adjustment and intelligent control of operating parameters in the coal preparation and utilization industry. In the present work, a real-time ash content analyzer based on dual-energy X-Ray Diffraction was developed. The feasibility of this X-Ray ash content analyzer was validated by the linear relationship between ash content and five characteristic parameters of X-Ray.

Furthermore, the wave filter, tube voltage, and current tube conditions were optimized. So what advantages of XRD outweigh the devices that applied XRF and γ-Ray?

The difference between XRF and XRD

The difference between XRF and XRD is simple: XRF analyzes Chemistry while XRD determines the mineralogy.

XRD identifies and measures the presence and amounts of minerals and their species in the sample and identifies phases.

XRF will produce an assay by giving information on the chemical composition of your sample without indicating what phases are present in your sample.

X-Ray Fluorescence (XRF) and X-Ray Diffraction (XRD) Analyzers provide qualitative and quantitative material characterization for detection, identification, analysis, quality control, process control, regulatory compliance, and screening for metals and alloys, mining and geology, scrap and recycling, environmental and consumer safety, education and research, and general manufacturing.

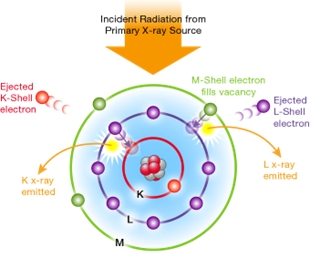

Moreover, X-Ray fluorescence (XRF) is a non-destructive analytical technique used to identify the elemental composition of materials. The XRF analyzer measures the fluorescence (or secondary) X-Rays emitted by the sample after being excited by a primary X-Ray source. Each element in the sample produces a characteristic set of fluorescent X-Rays, also known as a "unique fingerprint." The fingerprint of each component is different, making XRF analysis an excellent tool for quantitative and qualitative measurements.

X-Ray diffraction (XRD) is a non-destructive analytical technique that provides crystal structure information (crystallite size, % crystallinity, etc.), phase identification (e.g., minerals), and quantification of phases present in a sample. Modern XRD equipment is easy to use, can measure samples in minutes, and provides automated, quantitative analysis. As a result, XRD can quickly and efficiently determine coal quality, total ash, and amorphous carbon content in coal without needing standards, monitors, and calibrations.

In addition, X-Ray diffraction (XRD) is one of the most effective non-destructive tools for identifying and characterizing the crystalline structure, polymorphic structure, phase, and crystallinity changes of polycrystalline materials. By measuring the diffraction angle of a primary X-Ray beam according to Bragg's law (λ = 2d sinθ, where λ is the wavelength, d is the spacing between crystal planes, and θ is the diffraction angle), various polycrystalline materials in many research and industrial applications can be characterized and identified.

Comparison between XRD and Gamma-Ray ash analyzer:

More secure, easier to manage, and higher detection accuracy

- The X-Ray ash analyzer does not produce radiation after power is off, making maintenance safer.

- The X-Ray device is an electronic device and not a radioactive substance. Therefore, there is no half-life and no special requirements for transportation, storage, and recovery.

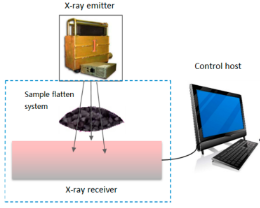

- The gamma-ray ash analyzer is a dual-source single-point sampling detection that can only detect a point area on the tape cross-section. If the material distribution on the tape is uneven, the detection accuracy will decrease. The fan-shaped detection of the X-Ray ash analyzer has a wide detection area, strong sample representativeness, and higher detection accuracy.

- Through the "self-learning" algorithm, the model is continuously automatically corrected to maintain a high level of detection accuracy at all times, and there will be no drifting phenomenon after a period of use.

Comparison with X-Ray fluorescence (XRF) ash analyzer:

- The detection area is vast. The X-Ray Diffraction is fan-shaped detection, and the detection area is extensive. At the same time, the fluorescent reflection is spot detection, and the detection area is small, with a single detection area only the size of a coin.

- Strong sample representativeness. Firstly, when the material's particle size, thickness, and bulk density change, the transmission has less impact, but X-Ray fluorescence detection accuracy is greatly affected. Secondly, in the complex environment of diverse coal types and significant fluctuations in coal quality, there will be differences in the coal quality between the surface and the inside of the coal flow. Only collecting surface signals will affect the detection accuracy.

- Strong environmental adaptability. X-Ray Diffraction technology has low ecological requirements and has been widely used in security checks, medical treatment, mineral sorting, and other environments. However, X-Ray fluorescence detection technology is best applied in a vacuum environment and is sensitive to dust and water vapor, affecting fluorescence reflectivity and reducing detection accuracy.

- Explosion-proof requirements. HOT's X-Ray ash analyzer has passed and obtained an explosion-proof certification. It can choose whether to be explosion-proof according to the actual site conditions.