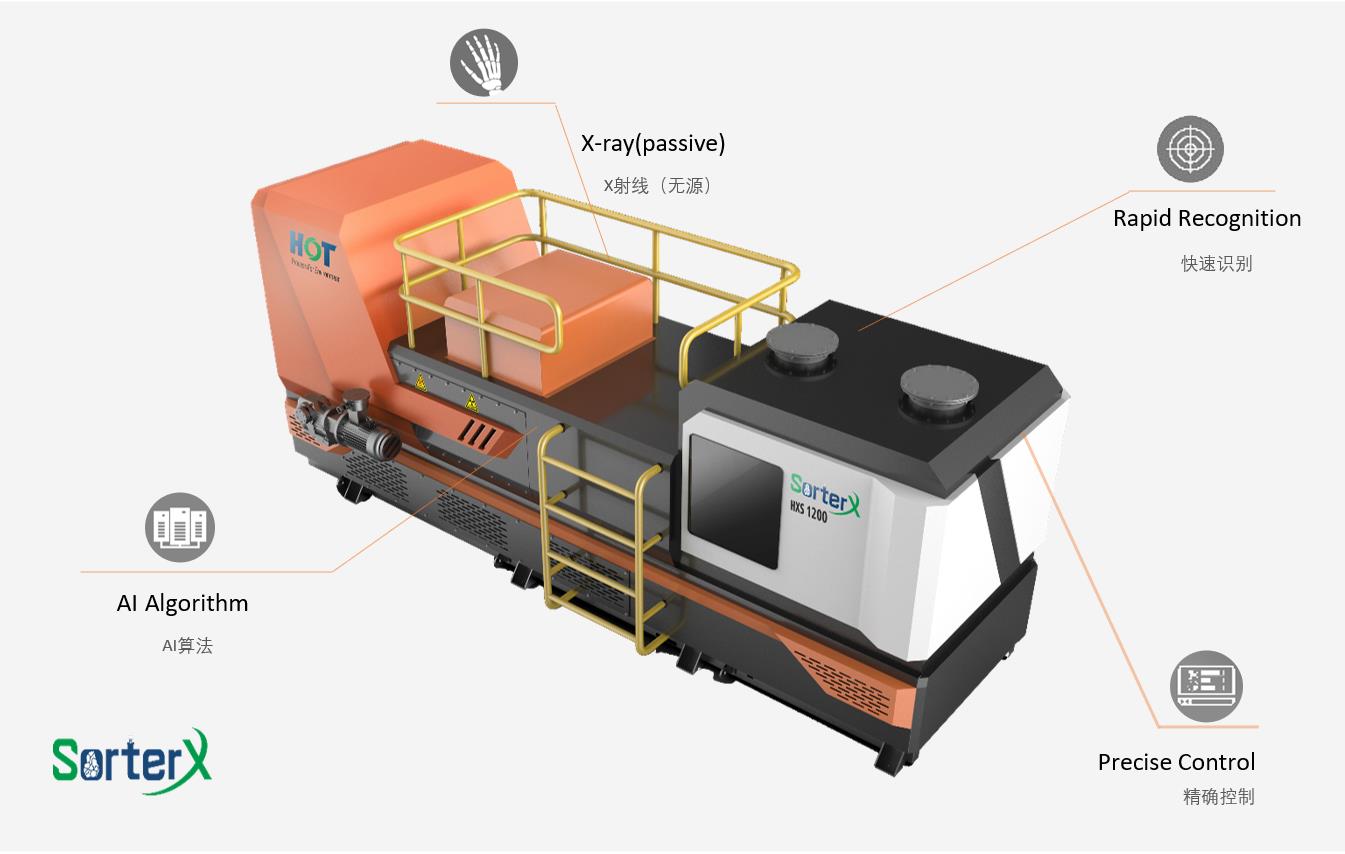

Taking an X-ray of the ore: Detecting the internal ore content, distinguishing between concentrate and tailings at a glance (sub millisecond response), and accurately sorting!

Gansu VESTA lead-zinc mine is a recognized jet-sedimentary modified ore deposit, one of the representative ore deposits in the western Qinling area. The lead-zinc ore body is in the clastic rock and carbonate contact zone, with sphalerite, galena, limonite, and chalcopyrite as the primary metal minerals. The ore structure is mainly banded reticulated, mottled, and angular gravel. After more than 30 years of development, the banded ore-free ore is less, currently dominated by sparse reticular and vein-like structures, which allows for high X-ray rejection. HOT XRT Sorter intelligent sorting equipment was introduced in 2022 with a targeted selection to improve the level and efficiency of the exploitation and utilization of mineral resources further to improve the ore grade of the mineral processing plant.

After one month of transformation and construction, HOT XRT Sorter intelligent sorting equipment was immediately put into production operation. Since it has been running for two months, the performance of the equipment is stable, and the sorting indicators are beyond the expectation of customers:

Through X-ray sorter pre-concentration, the ore grade entering the mineral processing plant can be effectively improved, the amount of ore entering the crushing and milling system can be significantly reduced, the production cost of ore dressing can be reduced, the production capacity of the mineral processing plant can be improved, and at the same time, the number of tailings entering the tailings pond can be reduced, the service life of the tailings pond can be extended, and the environmental pollution can be minimized d. It truly realizes the double promotion of economic development and environmental protection, makes a lengthy contribution to the enterprise's high-quality, green, environmental, and scientific development, and the predicted single HOT XRT Sorter can directly create an economic benefit of CNY 150 million for the mine. It is reported that the mine has adjusted its profit targets according to the operation data of the X-ray sorter.

Recently, in Tibet ZhongXin Mining, HOT XRT Sorter has been installed for three months that the sorter’s performance is also excellent and highly recognized by the cooperation partner.

The Sorting Performance On-Site (ZhongXin Mining):

Processing capacity of 75t/h (mine requirements 50t/h)

The operation rejection rate of 41.15% (Mine requirements 35.50%)

Lead-zinc tailings comprehensive grade below 0.28%

Tin tailings grade below 0.10%

HOT XRT Sorter can improve the comprehensive utilization efficiency of mineral resources, which is the key to the high-quality development of the mining industry and the specific action to practice the ecological civilization idea.

Through the intelligent sorting equipment for ore pre-concentration, it can effectively realize ore grade enrichment, reduce cost of the following process like gravity separation, froth flotation, tailing treatment and so on, improve beneficiation recovery rate, enhance the comprehensive utilization efficiency of mineral resources of mining enterprises and the risk resistance ability of enterprises, and truly achieve practical unity of resources, ecology, and approach highly ESG (Environment, Social and Governance) performance!

Contact us

Email: sales@hot-mining.com

Linkedin: Click here