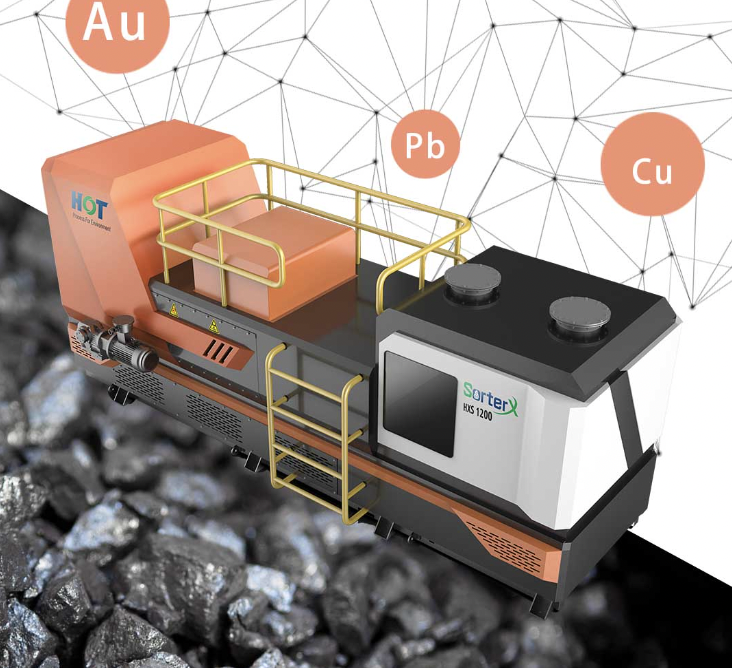

A difficult-to-select fluorite mine in Inner Mongolia has introduced HOT XRT Sorter, transforming fluorite lump ore from traditional manual selection and conventional processing to AI separation.

Through HOT XRT Sorter, fluorite lump ore can be sorted into concentrate, middling, and waste rock. The concentrate is directly sold as metallurgical-grade lump ore, while the waste rock is sold as sand and gravel aggregates. The middling is re-ground and re-selected, which can significantly reduce the amount of wet separation and greatly improve the economic benefits of the mine.

RUN OF MINE ORE

This difficult-to-select fluorite mine is a sedimentary transformed fluorite deposit, with the primary ore type being fine crystal block-like (sugar-like) fluorite ore. The ore color is grayish, making distinguishing ore grade by color challenging. Moreover, obtaining 97% grade fluorite powder through flotation is not easy, which belongs to a difficult-to-select fluorite mine.

HOT provides sampling guidance, free trials, on-site surveys, engineering design, installation, commissioning, and other services for this mine.

A three-product sorting process is used on-site. One piece of equipment achieves photoelectric sorting of 20-80mm (other particle sizes can be selected according to demand) fluorite ore blocks, selecting concentrate, middling, and tailings. Based on the high-grade ore grade in the original ore, the algorithm package can be chosen to obtain block concentrate with a grade of 60-80%, and the grade of middling is between that of concentrate and tailings. The concentrate is sold directly, the middling is re-ground and re-selected, and the tailings grade is 2-5%, sold as sand and gravel aggregates.

Midlling Ore Concentrate Ore Tailing Ore

Benefits of applying HOT XRT Sorter to the fluorite mine:

Taking 80% fluorite ore blocks and 97% flotation fluorite powder as examples, the two prices are similar. However, suppose 80% fluorite lump ore is directly selected from the original ore, compared with grinding and setting 97% fluorite powder. In that case, the yield will significantly increase (about 1.4t of 80% fluorite lump ore is selected to produce 1t of 97% fluorite powder). Photoelectric sorting costs less than CNY 5/t, much lower than flotation, and the benefits are much higher than flotation.

HOT XRT Sorter can pre-discard low-grade ore (2-5%) on-site during the crushing stage, with a discard ratio of 15-30% (related to the original ore grade). This part does not need to be re-ground and re-selected, saving processing costs. The on-site waste rock has a high hardness and can be sold as sand and gravel aggregates while reducing the discharge of tailings, which has comprehensive advantages.