Project Overview:

Committed to providing comprehensive "One-Stop" services and mineral processing consultancy services, HOT(Chengdu) Industries Co., Ltd undertook a technologically advanced project to improve the efficiency of concentrate loading through automation transformation and pollution prevention for a prominent copper dressing plant in Peru. This project demonstrates HOT Industries' technical capabilities and the innovative solutions devised to address pressing challenges encountered during the loading and transportation of mineral concentrate.

Identifying Challenges:

In this plant site, the final copper concentrate powder is stored in an inventory first, loaded into containers, and transported by trucks. Before the vehicles carrying the concentrate powder containers enter the loading area, forklift operators remove the container lids from the trucks and place them on racks. Once the concentrate powder loading is completed and the container tops are cleaned, the caps will be put back onto the containers similarly. This process requires high precision in operation and relies on experienced personnel, leading to low efficiency and significant labor intensity. Moreover, a small amount of concentrate powder residue may remain on the edge of the container tops in this process. Both the vehicles and the containers may also become contaminated with concentrate powder. The concentrate that falls from the containers may eventually disperse onto roads or transportation routes when attempting to fill containers using traditional methods (manual and imprecise operations), resulting in uncontrolled environmental impact and waste of resources. The left-over concentrate will also affect the accurate installation of the container tops.

Container Lid Removal

Truck Loading

Traditionally, high-pressure water guns have been used on-site for cleaning. However, this process heavily relies on experienced personnel to prevent water from entering the interior of the containers. Not only is this process inefficient, but it also causes significant dust pollution, posing occupational health risks. As for the concentrate contamination on both the vehicles and the containers, an ideal solution has yet to be found on-site. Therefore, an imperative need arose for a technology-driven resolution to improve loading efficiency, reduce labor intensity, mitigate worker risks, and minimize dependence on specific experienced personnel.

Traditional Cleaning Method with High-Pressure Water Gun

Designing Solutions:

Drawing upon technical expertise, HOT Industries designed innovative solutions to meet customers' demands regarding truck cleaning and container lid moving. The first task consists of a pre-cleaning stage and an entire washing stage. Although they both require an automated truck cleaning system, the former will be achieved using the waterless technique to clean the top part of the containers to avoid water entering the interior of the containers. On the other hand, the complete washing stage will be accomplished through high-pressure water washing to ensure thorough cleaning of the trucks' top, bottom, and sides, leaving no trace of the concentrated powder concentrate behind.

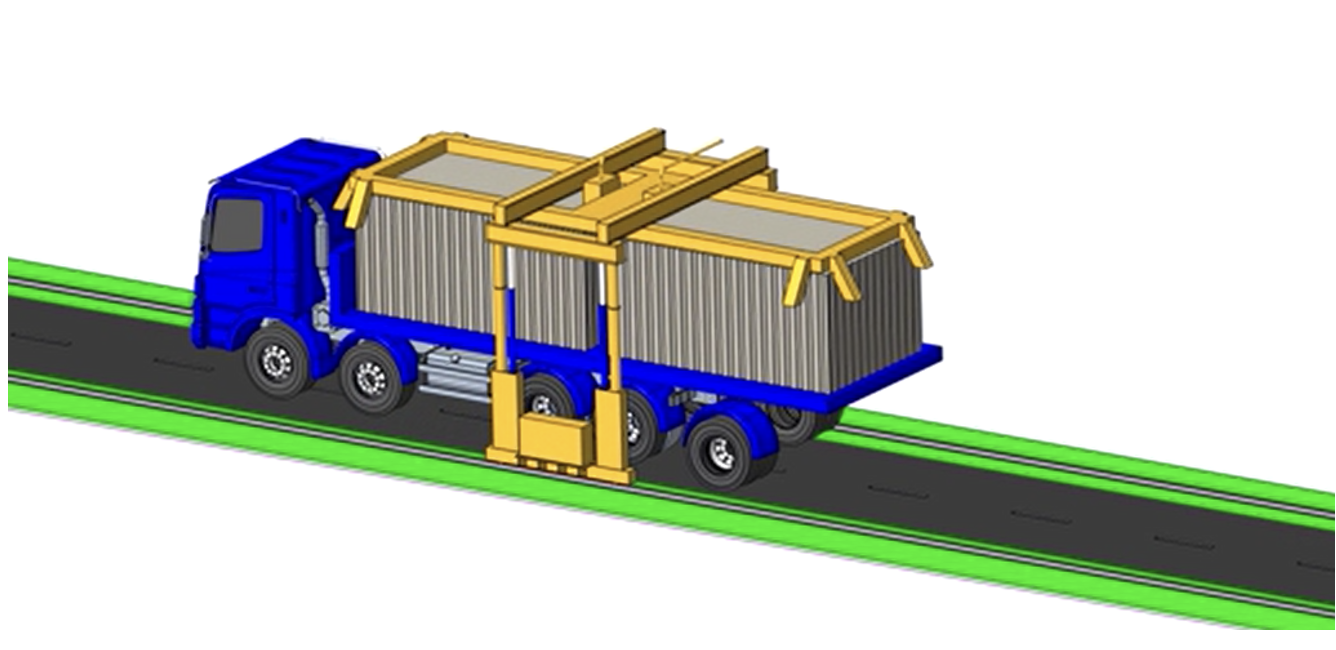

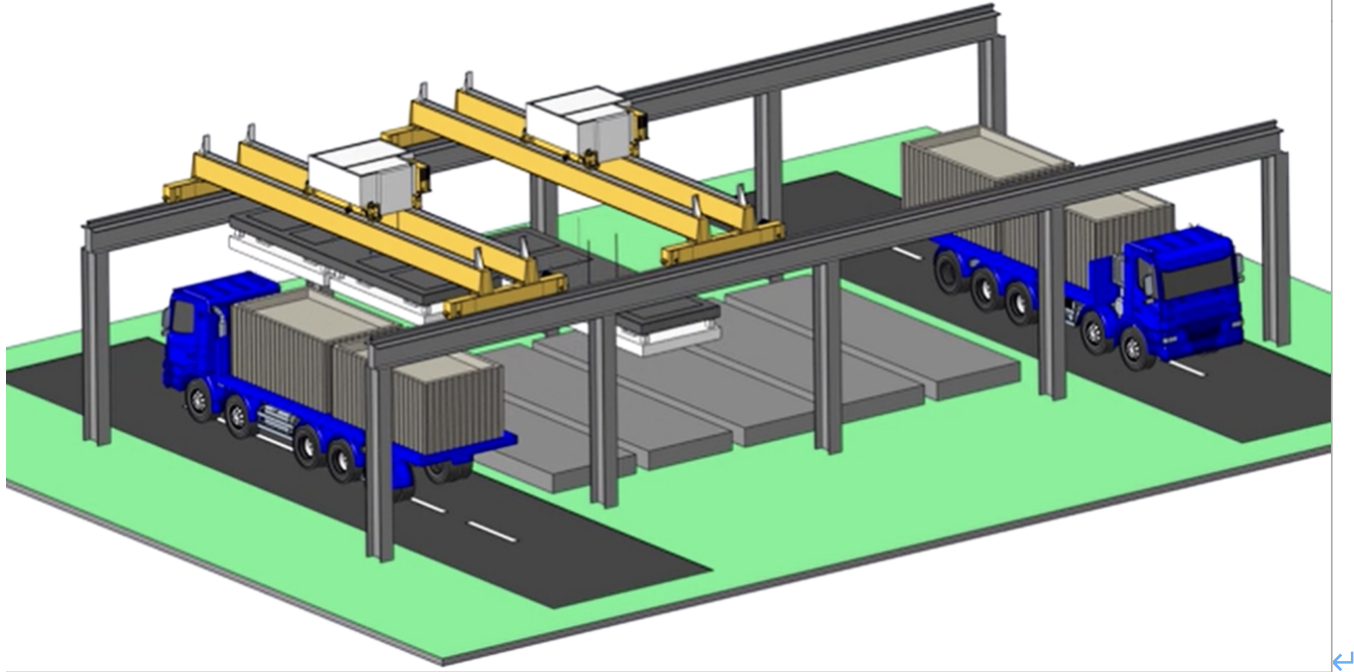

The system for moving container lids should be capable of removing the caps from both containers and placing them in the intermediate area of the lid holder. After loading the empty trucks, the lids should be collected from the lid holder and placed back onto the full trucks. All processes must comply with local requirements and be compatible with the existing mining facilities, including power needs and concrete structures.

Implementation and Execution:

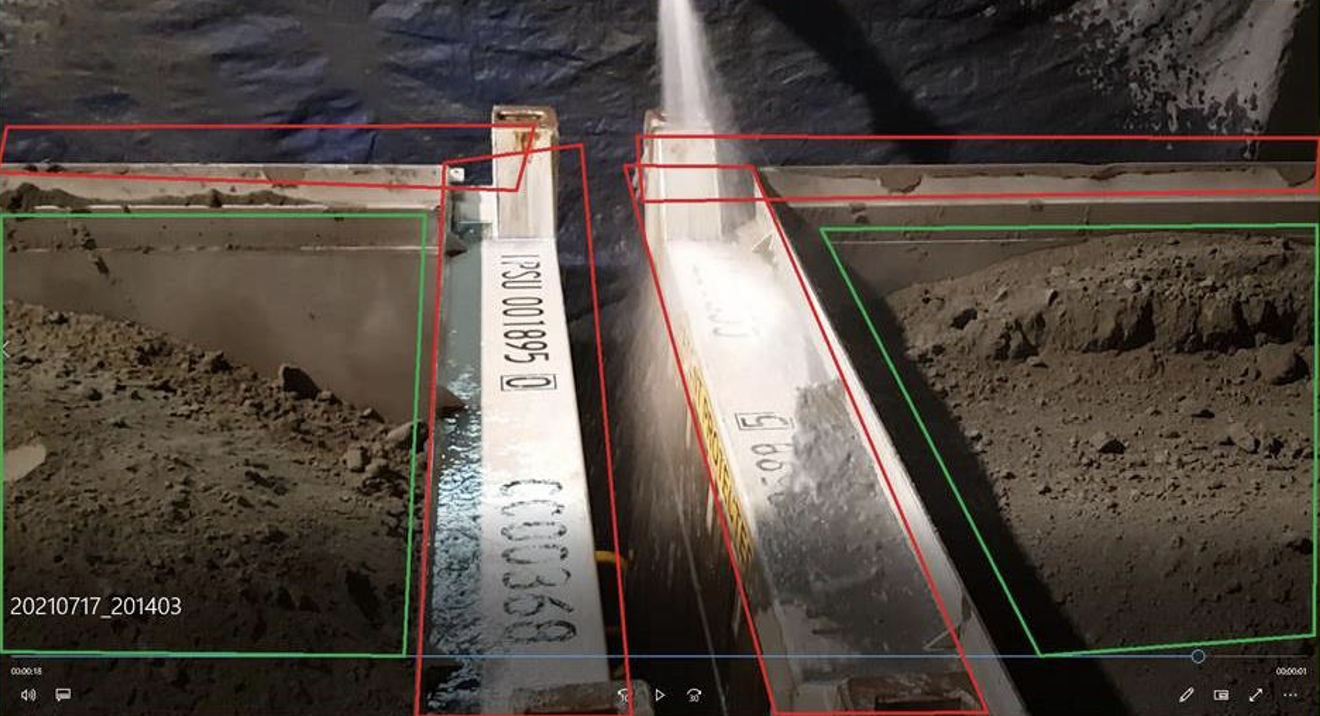

HOT Industries puts forward an air cleaning system with a unique design for the pre-cleaning operation. The copper concentrate residue on the upper surface and edges, as shown in the picture as the red areas, will be cleaned so that the container lid can be correctly placed afterward. Meanwhile, the green space where the concentrated powder will be loaded remains dry, and a dust-collection system is implemented to avoid generating dust particles and discharging concentrates into the surrounding areas. A truck cleaning station with high-pressure water guns will be installed outside the construction site, where trucks will be cleaned after loading.

HOT Industries Customized Container Top Pneumatic Cleaning System (Enclosed Workshop and Dust Collector not shown)

HOT Industries Supplied Fully Automated Whole Vehicle High-Pressure Water Washing System

Top area of the containers

Considering the existing design of the pillars and roof might not be sufficient to withstand additional loads and the limited space between the trucks and the roof columns, a fully automated overhead crane system that could be controlled remotely will be installed independently in which no operator was needed. The system moves container lids back and forth between the empty truck path and the full truck path. The crane has a rotating mast mechanism to ensure a flexible and precise operation. The system can operate in full automation or semi-automation mode, significantly reducing the labor intensity for personnel and improving loading efficiency. All designs can continue operations even during thunderstorms, rain, or adverse weather conditions.

HOT Industries Customized Top Cover Automated Continuous Loading and Unloading System

Conclusion:

This groundbreaking project exemplifies the technical capabilities and unwavering dedication of HOT Industries toward catalyzing transformative change within the mining sector. The company provided satisfactory and innovative services through automation and the integration of advanced technologies, achieving commendable results for the client. Looking forward, this project serves as a seminal precedent for the future transformation of the resource industry. HOT Industries remains steadfast in pioneering innovative solutions encompassing eco-friendly practices, workflow optimization, and favorable industry impact. Envisioning further collaborations and projects, the organization redefines industry standards and establishes new benchmarks for sustainable mining practices.