Optimizing the efficiency and effectiveness of coal preparation processes is crucial for the mining industry, and one key aspect that plays a significant role is the utilization of filter presses. Filter presses are essential equipment for separating solids from liquids in the coal preparation process, aiding in the production of refined coal, tail coal, and unsorted slime filter.

Fig1.Filter Press HOT

1. Filter Press Type Selection

At present, the type selection of filter press in the field of coal preparation is relatively simple. The flow filter press for flotation refined coal, the 30kg medium pressure filter press for tail coal, and the ultra-high pressure filter press for unsorted slime filter are roughly this concept.

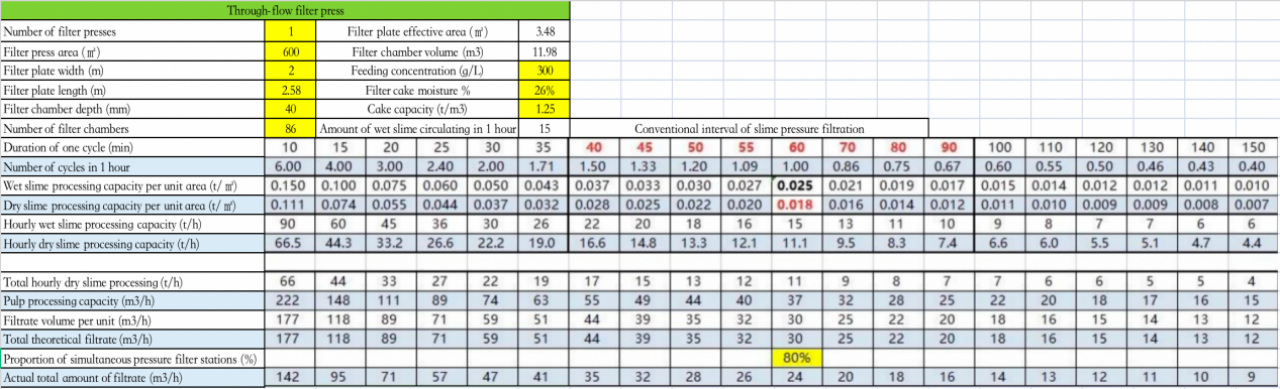

First look at the selection of conventional filter press and medium pressure diaphragm filter press reference table.

The above is an example of a 600-square-meter filter press, the depth of the filter chamber is 40mm, and the filtration time of a cycle varies from 10 minutes to 150 minutes. In the field of coal preparation, it is difficult to see a cycle time that can be completed in 20 minutes, but it can be achieved in some cases, such as the sand and aggregate industry, to do such a large range of table calculations, mainly to deal with some special cases. Coal slime filter conventional flotation refined coal for more than 40 minutes, so a 600 square meters filter press, the processing capacity is about 16t/h, the flotation tail coal filter time is much longer, such as 1 hour, the same area of processing capacity is 11t/h. Some extreme cases have reached 2 hours, then the processing capacity is 5.5t/h, and the coal slime with high tail coal ash content is not only difficult to press, but also high water after pressing. At the same time, you can pay attention to other parameters in the table, such as the concentration of feed, the amount of filtrate, etc., are for easy understanding and easy query during design.

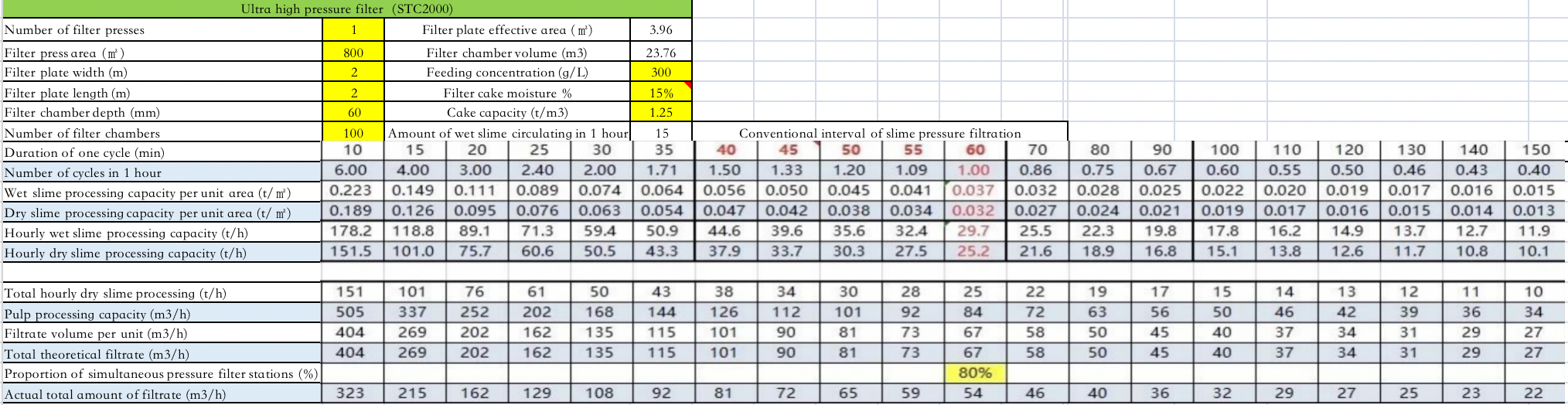

And here is an Ultra-high pressure filter press basic process parameters table:

Ultra-high-pressure-filter-press-process-parameters-HOT

The ultra-high pressure filter press has a large processing capacity per unit area due to the thickness of its filter chamber reaching 60mm. The above is the basic situation of STC2000, if the slime is good pressure, water 12%, if the water is not good pressure 20%, this depends on the nature of the slime, of course, the ultra-high pressure filter press mainly filters the unsorted slime, the ash content is less than 30%, in order to reduce the water and increase the heat for the purpose. In general, one cycle of pressure per hour, that is, 25t/h. This makes selection easy.

The most difficult thing to judge is how long it takes to press a cycle, which is mainly solved by doing pre-pressure tests, investigating the production situation of surrounding coal preparation plants, or accumulating different coal slime ash and coal slime particle size composition. Manufacturers should also accumulate the special features of each project in order to provide better selection guidance.

It is worth mentioning that when there are coarse particles in the filter cake, it will break when it is removed from the filter press to the scraper. The material is basically loose. After the tail coal is filtered by high pressure, the filter cake is laminated, and it is not easy to break, and the block is too large, so it needs to be broken, and then mixed into the final coal. The better the filtered material, the easier the filter cake is to break, like flotation cleaned coal, generally do not need to add slime crusher, tail coal is difficult to filter, filter cake compaction, if you want to blend, you need to add slime crusher.

Fig.1 HOT Filter Press

Fig.2 HOT Intelligent Filter Press

2.Filter Press Feed Pump

The feed pump of the filter press is very critical. Some flotation cleaned coal filtration speed is fast, the pump selection is small, the press filtration process is slow, can not keep up with the rhythm, and the press filtration time is longer. Tail coal press filtration, slow filtration speed, large selection of feed pump high energy consumption, late feed, the pump in idling, increasing wear. The lift of the pump is high, and the filter plate of the filter press can't stand it. However, in most cases, the selection of the filter press feed pump has not attracted the attention of the relevant personnel. According to the speed of filtration, the size of the filter press area, select the feed pump. It is not that the flow of the feed pump is large, the filtration speed is fast, it should be the other way around, the pump should adapt to the nature of the material.

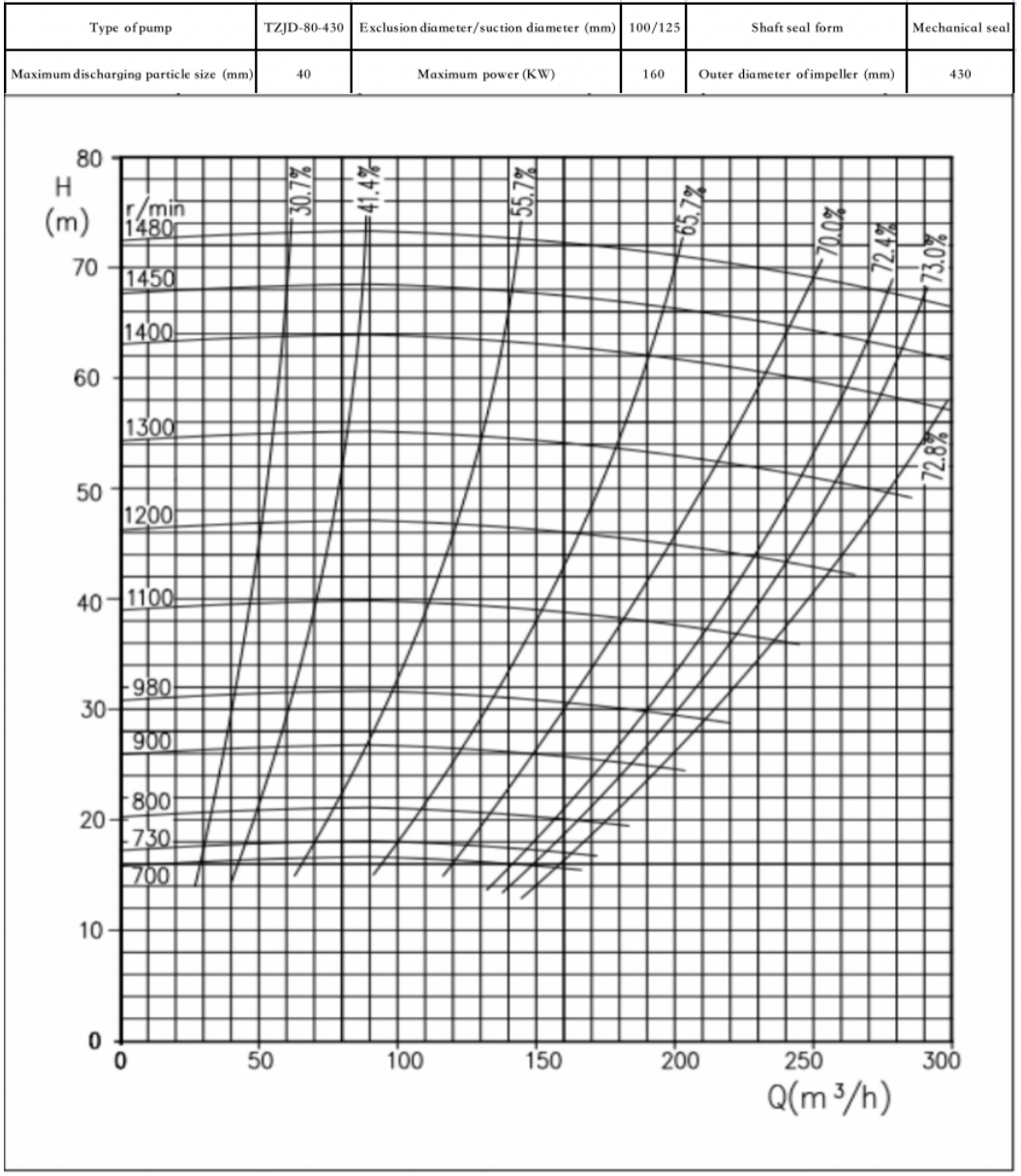

In terms of the conventional 600m2 clean coal filter press, it is reasonable to choose a centrifugal pump with 240m³/h and a head of 65m.

Taking the slurry pump curve of Zhanggu as an example, when the flow rate of the pump will become smaller and the pressure will increase in the later stage of feeding, the following pump can be selected, the performance curve is gentle, and the head change caused by the flow rate change is small. Of course, 65 meters is not considered the height of the layout. The pressure of the feeding pump can not be too high, otherwise the cylinder can not be topped, and high pressure pressing can be achieved, mainly with a locking device, rather than the cylinder.

Filter-press-feed-pump-parameters-HOT

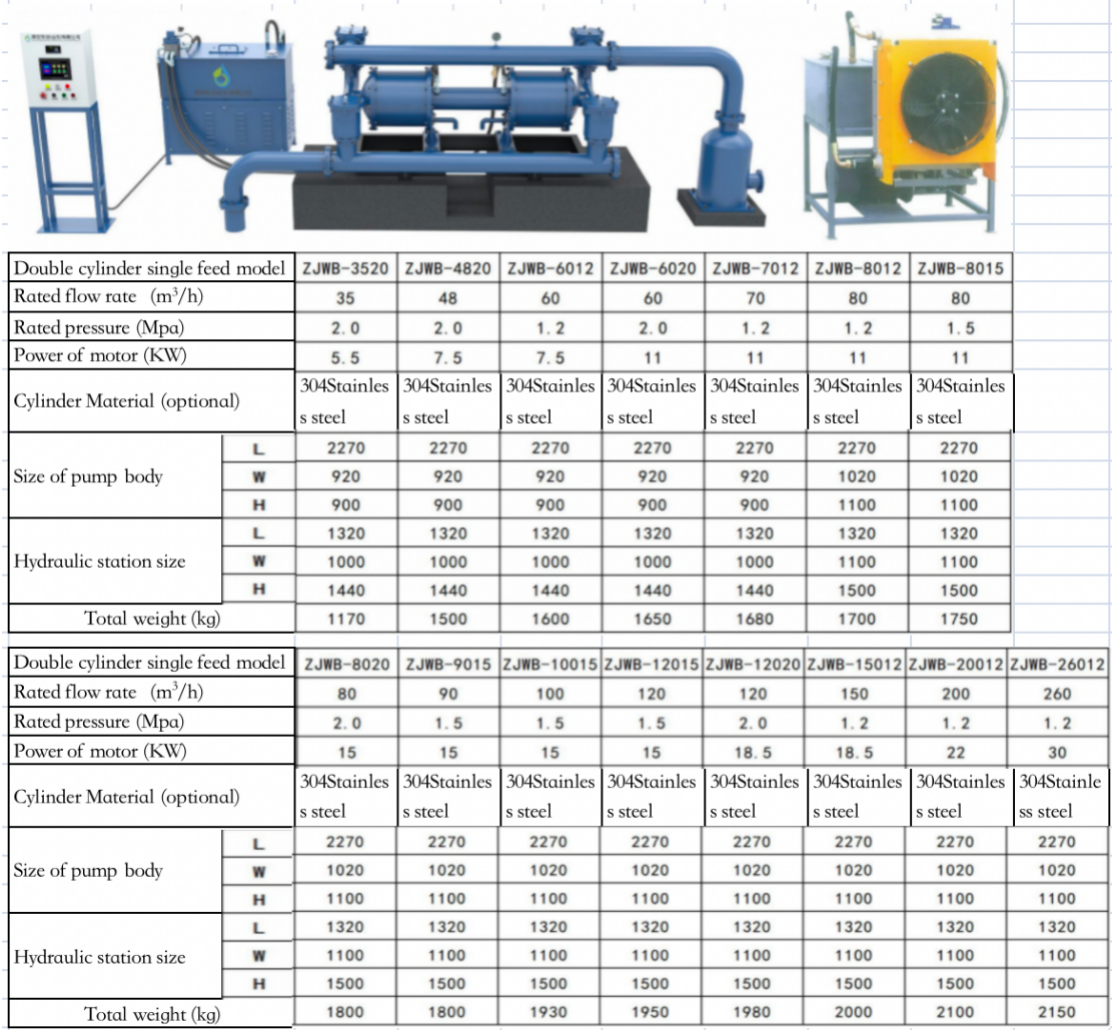

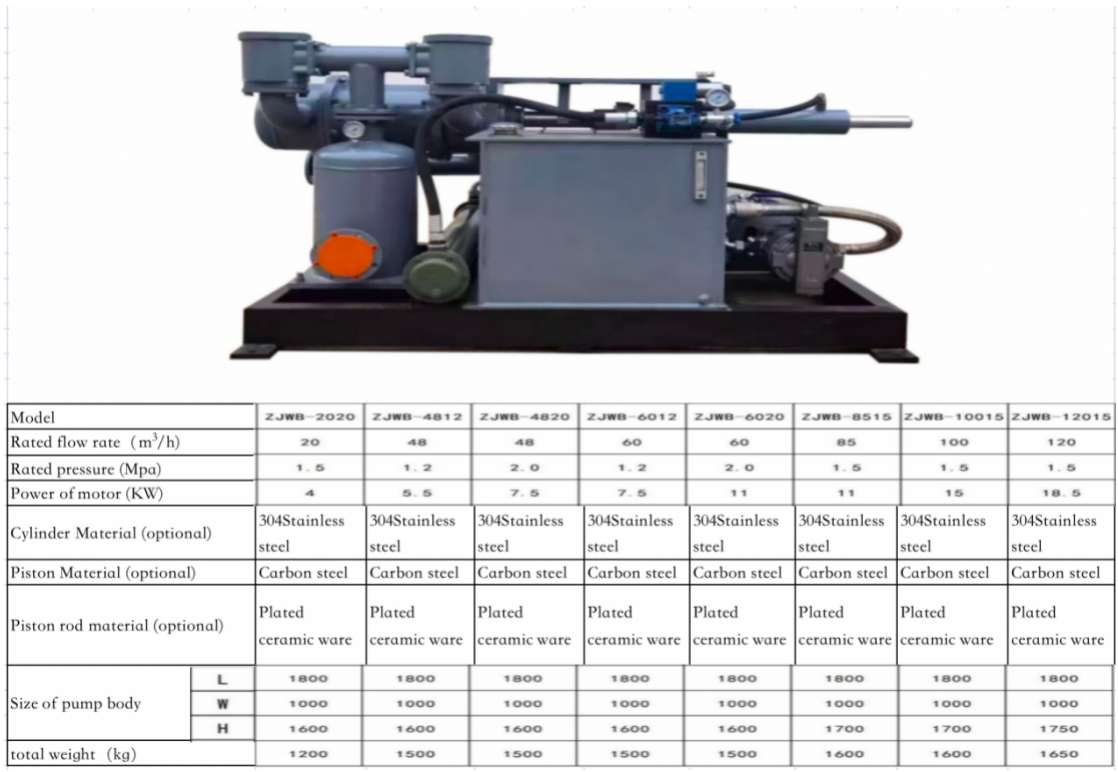

For 600 square meters of tail coal filter press,it is more reasonable to choose 120m³/h and 0.8Mpa piston pump (variable frequency adjustable).

The biggest advantage is low power and energy saving. According to 120m³/h selection, the power is only 18.5kw, and some unreasonable selection 240m³/h, H=80m³/h, its power is 110kw, or 132kw, this gap is quite large. The following figures are the two cylinder piston pump and the single cylinder piston pump, the rated pressure is adjustable.

3.Transformation of Filter Press

In recent years, the level of China's filter press has improved significantly. The main performance is the reduction of product moisture, and the reduction of the price of filter press equipment, which is a good thing. Flotation clean coal external water 20% ~ 22%, this indicator a few years ago was 26% ~ 28%. Floatation tail coal filter cake moisture is now 25% ~ 28%, this index was 36% a few years ago. With the gradual reduction of coal resources and the progress of filter press technology, in the huge stock market, customers want to achieve low slime moisture and do not want to invest too much. Therefore, the transformation of the filter press is a feasible way.

3.1 Clean coal press filtration reform

In 2012, a coal preparation plant installed two HMZG800/2000-U type high-efficiency diaphragm filter press for flotation clean coal filter, according to the technical requirements of the old process design, the product moisture is about 26%~27%, and the filter cake moisture is high. Under the condition that the basic conditions of the original equipment remain unchanged, the water content of floating cleaned coal after the transformation is about 20%~22%.

There are three methods of transformation:

Transform on the original filter plate, install the blower function, and increase the capacity of the gas storage tank (20~30m³). The tail plate opens a blow hole, and the hole is reformed in the coal preparation plant, the transformation cost is low, the transformation period is short, and the effect is visible, and the production of the original coal plant is not affected or the impact is small.

Replace the full set of filter press plate, increase the air blowing function, increase the air storage tank, and open the hole at the tail end of the filter press. Reduce the water content of floating cleaned coal. The cost is expected to be around 500,000.

Replace the new process piercing flow filter press equipment on the basis of the original equipment. The cost is estimated at; 800,000 to 1 million yuan.

3.2 Transformation of tailing coal press filtration (high ash tailing coal)

In 2011, a coal preparation plant in Shaanxi installed 5 sets of KMZG500/2000-U type efficient diaphragm filter press, which was originally used for primary filter press. After the coal slime flotation project was put into use in 2019, the properties of the feedstock slime by the filter press changed greatly, and the ash content of the feedstock slime increased from about 45% to about 70%, not only the ash content increased, but also the fine coal particles in the tail coal did not or reduced, and there was no smooth water filter bridge channel; The proportion of ultrafine components or rare earth components in the tail coal increases, the filter water bridge channel is reduced, and the filter cloth is directly pasted, resulting in high water content of the filter cake of the filter press, slow filtration and other problems. The average water content is as high as 36%-37%, and the filter press has a cycle of 2.5 hours. (In some cases, the filter mixing process can be considered) the core is serious, the belt slippage cannot be transported, and the filter cake is difficult to load and transport.

Transformation method:

Increase the pressure of the diaphragm filter plate, replace the water press filter plate, increase the press pressure to 1.6mpa, increase the blowing time, can effectively improve the filter cake sandwich condition.

The old equipment is replaced by 3.0 type filter press, and the pressure of water pressing diaphragm filter plate is increased to 3.0mpa, and the coal slime is not quantified. Thoroughly solve the problem of high water content of filter cake and difficult treatment of slime. Recycle old equipment.

Replace the energy saving plunger pump and increase the feed pressure (mentioned in the second part). The installation size of the equipment is short, simple fixed installation can be used on the ground, suitable for use in restricted locations.