Applicable Ore Types: Lithium Ore, Nickel Ore, Coal (Ash and Multi-Element), Lead-Zinc Ore, Copper Ore, Iron Ore, Phosphate Ore, etc.

1. Research and Development Background

In 2022, China continued to increase its research and development (R&D) investment, with a continuous emphasis on research intensity. The R&D expenditure for the mining industry reached 46.6 billion yuan, setting a new high in the past decade. Specifically, the R&D expenditure for non-ferrous metal ore mining was 3.56 billion yuan, black metal ore mining was 4.41 billion yuan, coal mining and beneficiation was 18.26 billion yuan, and non-metallic mineral ore mining was 3.22 billion yuan, totaling 29.4 billion yuan. Against the backdrop of increased national investment in R&D, HOT (Chengdu) Industries Co.,Ltd developed an intelligent sensing system for flotation reagent addition based on real-time measurement of ore slurry elemental grades. The most urgent need in intelligent sensing is the online measurement of multi-element ore grade.

2. Knowledge Overview

Current elemental detection methods can be categorized as active and passive:

·Active: Gamma-ray methods such as dual-energy gamma-ray transmission and neutron activation measurements.

·Passive: Natural gamma-ray measurements, Laser-Induced Breakdown Spectroscopy (LIBS) for coal composition analysis, X-ray fluorescence analysis (XRF), and multi-energy X-ray absorption (XRT). Passive radiation has lower energy intensity and is much less harmful to humans compared to active radiation. LIBS technology can analyze industrial components, composition, and elemental content.

3. Current Challenges

Intelligent flotation plays a crucial role in the construction of intelligent concentrators. On the one hand, online slurry ash measurement is a key technical issue for grade control in intelligent flotation control systems, with grade being an important parameter for determining ore dressing parameters and evaluating ore dressing efficiency. On the other hand, online detection and real-time feedback of slurry grade are beneficial for guiding the production process, controlling reagent dosages to achieve cost savings, product quality control, and improving recovery rates. To achieve the intelligence of the entire concentrator system, intelligent flotation system must be implemented, and to achieve intelligent flotation system, the key problem of online slurry ash measurement must be solved.

4. Research Background

Real-time elemental analysis is the foundation of intelligent flotation.

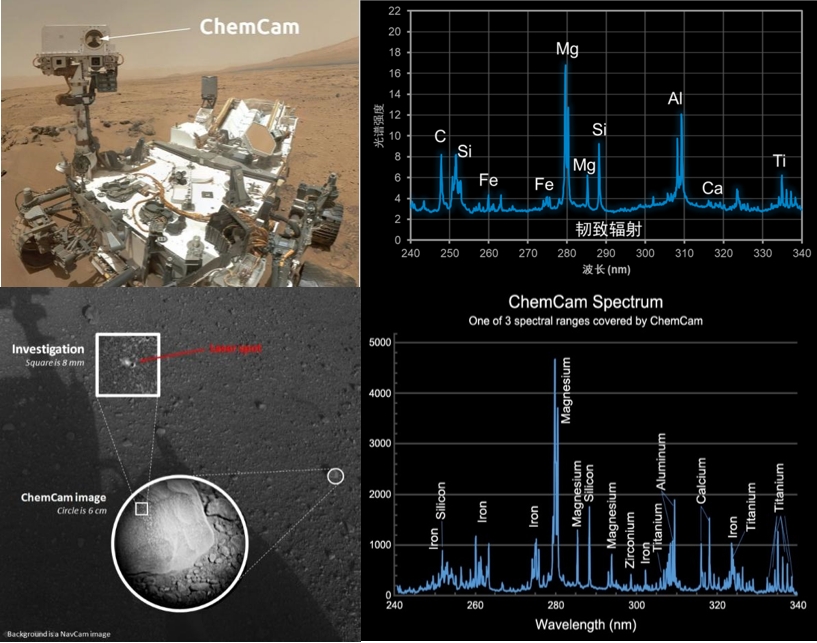

Laser-Induced Breakdown Spectroscopy (LIBS) technology is an emerging technology for mineral element analysis (originally used in Mars rovers).

Figure: Mars Rover Exploration and Spectrum Analysis

5. Solution

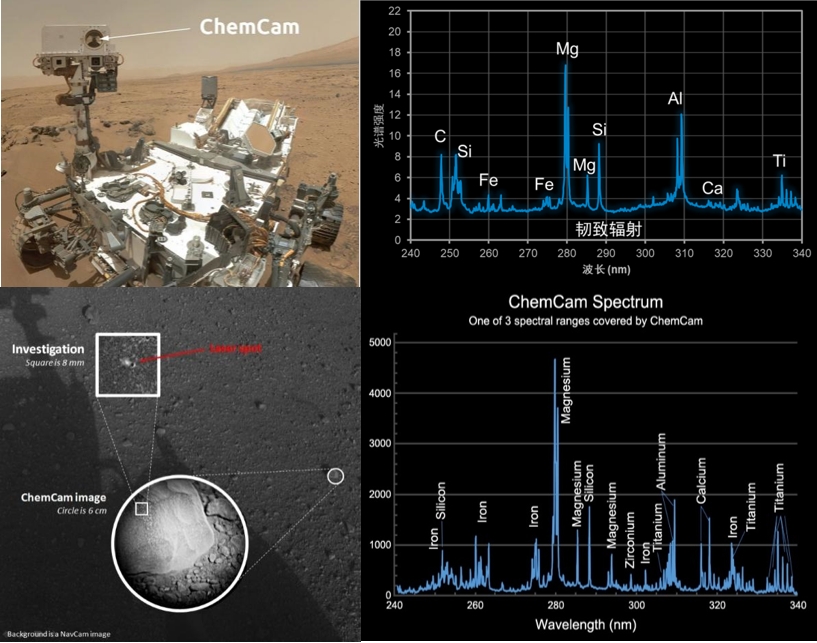

Technical Principle of the solution: Excited-state atoms (i.e., ions) have a one-to-one correspondence with atomic spectra and can be used for element identification.

Figure: Ion-Induced Excitation Principle

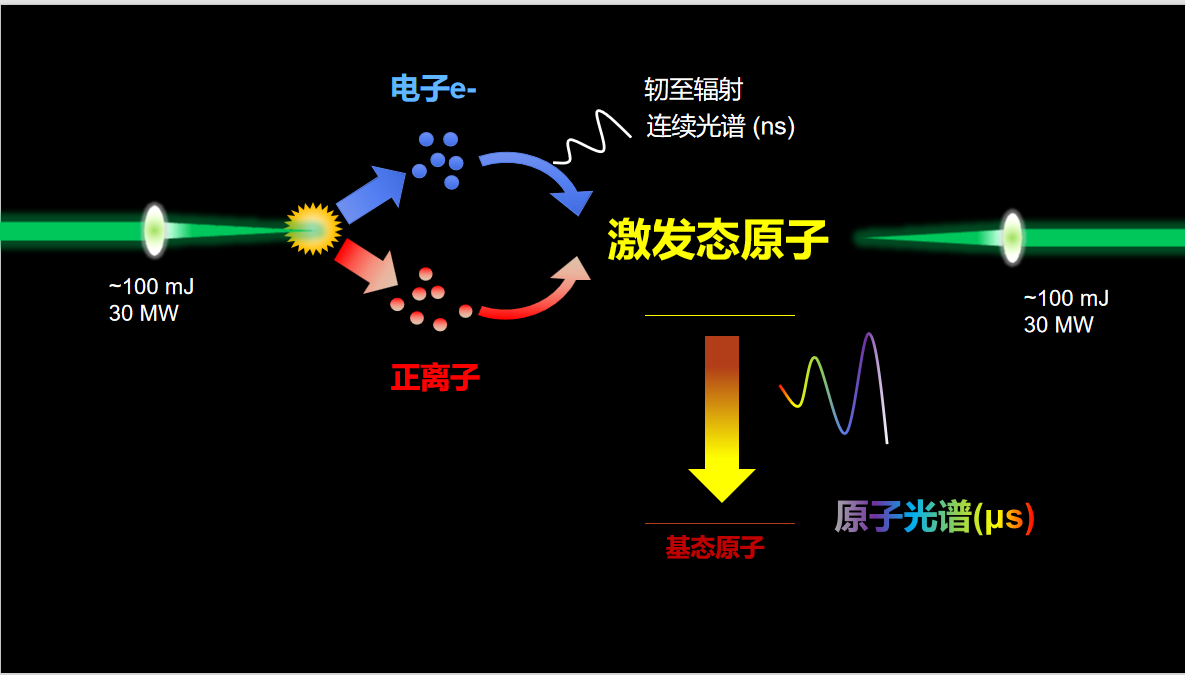

Figure: Measurement Principle

The technology is now applied to real-time slurry grade detection, as follows:

Figure: Real-time Detection Scheme

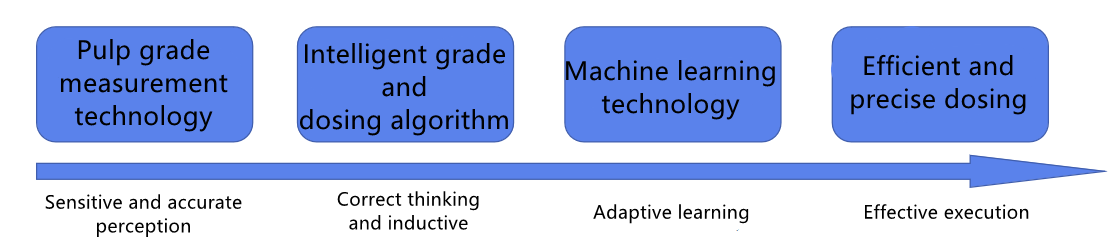

5.1 Technical Route:

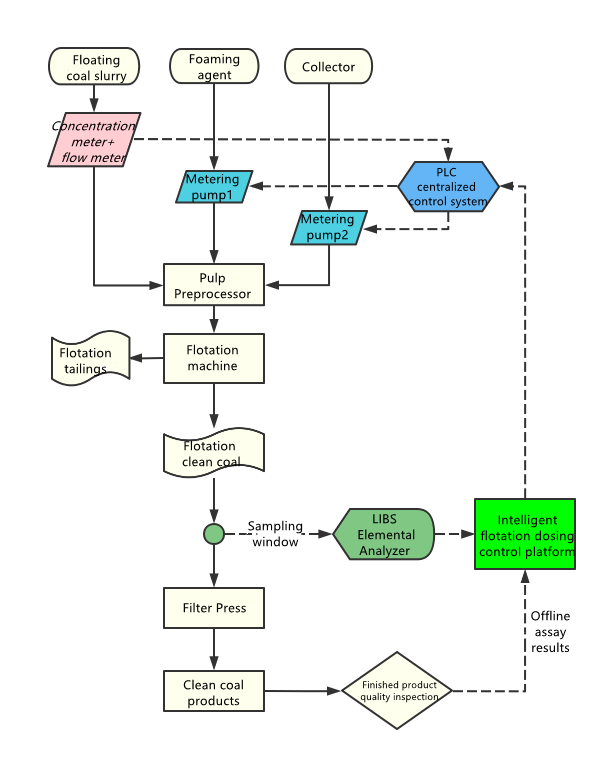

1. The LIBS elemental analyzer obtains the grade through a sampling window on the pipeline and transmits it to the intelligent flotation reagent control platform.

2. The PLC centralized control system obtains the concentration and flow rate of the incoming ore slurry through density and flow meters, calculates the slurry volume, and transmits it to the intelligent flotation reagent control platform.

3. The intelligent flotation reagent control platform, using big data and artificial intelligence technology, analyzes the appropriate reagent dosage and sends control signals to the PLC centralized control system.

4. The PLC centralized control system receives the reagent dosage signal and adjusts various parameters, such as frother flow rate for flotation.

5. The original offline assay results from the laboratory are used to periodically calibrate the accuracy of the elemental analyzer's measurements.

Figure: Intelligent Coal Flotation Process Flowchart (Example for Coal Preparation Plant)

5.2 Salt Lake Lithium Solution:

Laser-Induced Plasma Technology is an advanced elemental content measurement technology that can be used for component monitoring in solid, liquid, and gas samples. It features non-destructiveness, no sample preparation, online measurement, a wide dynamic range, and high precision. In lithium chloride brine, the content of lithium chloride is very low, often ranging from hundreds to over a thousand ppm. Lithium is the third element on the periodic table, with few outer electrons (highly reactive) and a small nucleus, making it difficult to resonate with X-rays and gamma rays. However, it is easily excited to generate plasma by laser. Therefore, LIBS technology is almost the best choice for online monitoring of lithium chloride brine grade.

Technical Route: For lithium chloride brine grade monitoring, optical windows can be directly opened on the conveying pipeline to directly measure the liquid inside the pipeline using LIBS. On representative conveying pipelines in the brine refining process, a branch line is set up for measurements, with additional control valves, booster pumps, and flow meters to ensure consistency with the main pipeline flow, ensuring the "constant speed sampling" principle. The branch line is square in shape and equipped with sapphire or quartz windows for LIBS measurements. By simultaneously measuring the proportions of Li, Mg, K, Na, and H elements, the Li concentration in the brine can be provided, as well as parameters such as Mg/Li and K/Li. LIBS laser uses high-energy dual-pulse second harmonic wavelength laser to enhance excitation intensity, reduce detection limits, and reduce the influence of water matrix effects. A patented "compound eye" plasma spectral reception design greatly increases the system's light intake. The spectrometer is designed in segments, covering a wavelength range of 250-800 nm, with a resolution better than 0.1 nm, providing high detection limits.

6. Equipment Advantages:

·High degree of automation and intelligence, computerized control of sampling, measurement analysis, daily sampling, and data processing.

·Stable and reliable data analysis.

·Safe and environmentally friendly, no radioactive sources, no need for approval from environmental protection authorities.

·Convenient operation and maintenance, modular design, high integration of functions, small size, and easy operation and maintenance.

7. Economic Benefits & Technical Indicators:

7.1 Coal Mining

When producing 2# clean coal, the ash content of the floating concentrate is <9.5%, with a stability rate of over 90%. When producing 5# clean coal, the ash content of the floating concentrate is <15%, with a stability rate of over 95%.

When producing 2# clean coal, the floating concentrate extraction rate increases by 0.5%. When producing 5# clean coal, the floating concentrate extraction rate increases by 1%.

Reagent consumption reduced by 20%.

With 2 million tons per annum (Mt/a) production and 10% flotation input (raw coal slurry plus secondary coal slurry), the average increase in flotation recovery rate is 1%, resulting in an annual additional recovery of 1,980 tons of clean coal. The net price of clean coal is calculated at 1,050 yuan per ton, resulting in an economic benefit of 2.08 million yuan per year. Adding the benefit of reduced reagent consumption at 400,000 yuan per year, the project benefit is 2.48 million yuan per year.

Reduced flotation, sampling, sample preparation, and assay personnel, reducing labor costs.

7.2 Salt Lake Lithium Mining

·LiCl detection limit: 6 mg/L.

·LiCl concentration measurement accuracy: ±10 mg/L @ 1000 mg/L.

·Measurable parameters: LiCl, MgCl, KCl, NaCl concentration, and Mg/Li, K/Li, etc.

·Reduced flotation, sampling, sample preparation, and assay personnel, reducing labor costs.

·Provides analysis results every minute, or calculates results for any desired time and time interval based on user needs.