Application of Artificial Intelligence in the Selection of Nonmetallic Mines!

The CCD Color-Sorting machine can apply to pre-concentration of nonmetallic ore; it is used to identify the differences in physical properties (optical, radioactive, magnetic, electric, etc.) that are easily detected according to the different components of ore and separate the ore or waste rock by specific external features.

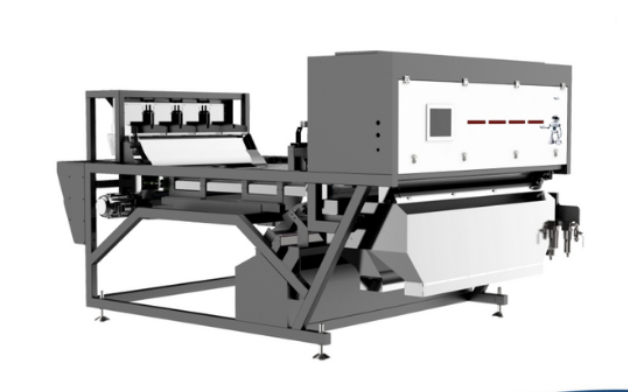

Color sorting machines can be classified and compared according to their architecture: belt and trough types. The belt color sorting device has many materials, high color sorting accuracy, low damage, high yield, small take-off ratio, and can be directly packed after selection. The damage to materials is relatively minor, and the damage is negligible. In addition, the speed is controllable, the yield can be adjusted, and the design can be done precisely according to the customer's production, but the cost is relatively high. The trough color sorter is suitable for traditional materials. However, the color sorting effect could be better for materials with significant differences in shape and size. After the color sorting is completed, the material will still be accelerated for a long time, increasing the damage to the material and resulting in a high breakage rate. In addition, the structure of the trough color sorter is fixed, the speed is set, and the output is also fixed.

Application of color sorters in the nonmetallic industry Color sorters can not only be used for the selection of agricultural products but also the selection of many nonmetallic mines, such as potassium feldspar, heavy spar, quartz sand, fused quartz, calcium carbonate, marble, dolomite, wolframite, and phosphorus ore. Here, we take potassium feldspar and quartz sand as examples to introduce the application of color-sorting machines in nonmetallic minerals.

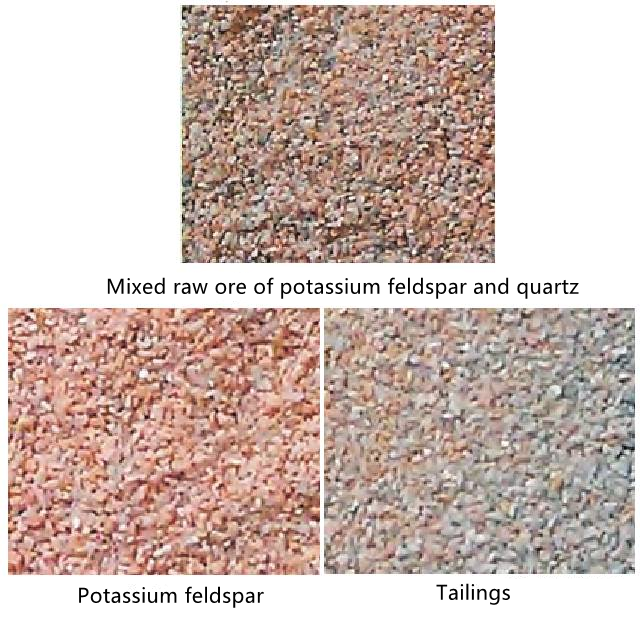

Application of color sorters in the selection of potassium feldspar Taking the mixture of potassium feldspar and quartz as the sorting object, using the apparent differences of potassium feldspar with reddish flesh color and quartz with transparent or milky white color, color sorters are used for the selection.

For potassium feldspar as the sorting target, the ore particle size is controlled between 3-10mm, and a certain sorting threshold is set for sorting. By measuring the potassium grades of the original ore before sorting and the enriched potassium feldspar after sorting, it was found that the enrichment ratio of potassium was 1.3, and 35% of the waste rock was discarded, which had an excellent sorting effect.

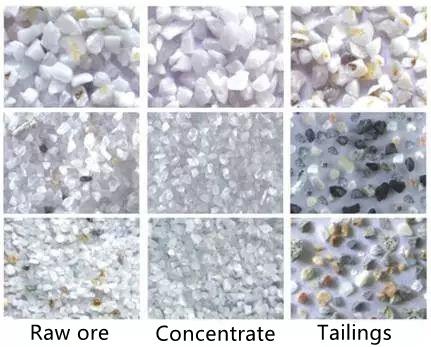

The application of color sorter in quartz sand ore sorting Quartz sand ore in the raw ore, the purer quartz sand is white or milky white, iron impurity or its vein minerals have light yellow, light yellow or light brown and gray color, quartz sand and iron impurities, or vein minerals color difference is the key of color sorting.

Quartz sand and vein mineral jet separation

The main factors affecting the color sorting effect are camera resolution, software algorithm for distinguishing color differences, feeding system, and nozzle working performance. The camera is equivalent to the "eyes" of the color sorter. The higher the camera's resolution, the clearer the color sorter will "see" and provide the basis for accurate judgment of the materials the color sorter. The software is equivalent to the "brain" of the color sorter, determining its ability to distinguish color differences. The software algorithm analyzes the data seen by the camera, to a certain extent determining the intelligence of the color sorter and the "ideas" of the color sorter for the materials. The feeding system determines how the material enters the "field of view" of the color sorter and leaves after sorting. Finally, the nozzle is the "hand" of the color sorter, and the command is sent to the nozzle to execute after the "brain" of the color sorter judges the color of the material, so the flexibility and stability of the nozzle finally determine the sorting effect of the color sorter.